DISASSEMBLY

To change timing belt and/or pulleys, or to

remove spindle pulley prior to spindle removal,

proceed as follows:

1. Disconnect and lock out power source.

Remove feed assembly and reduction

head. See “Disassembly”, pages 44—52.

2. Remove cover plate and belt guard. See

“Covers & Guards”, page 38.

3. Loosen motor mount fasteners and slide

motor toward spindle until timing belt

drops. Remove timing belt.

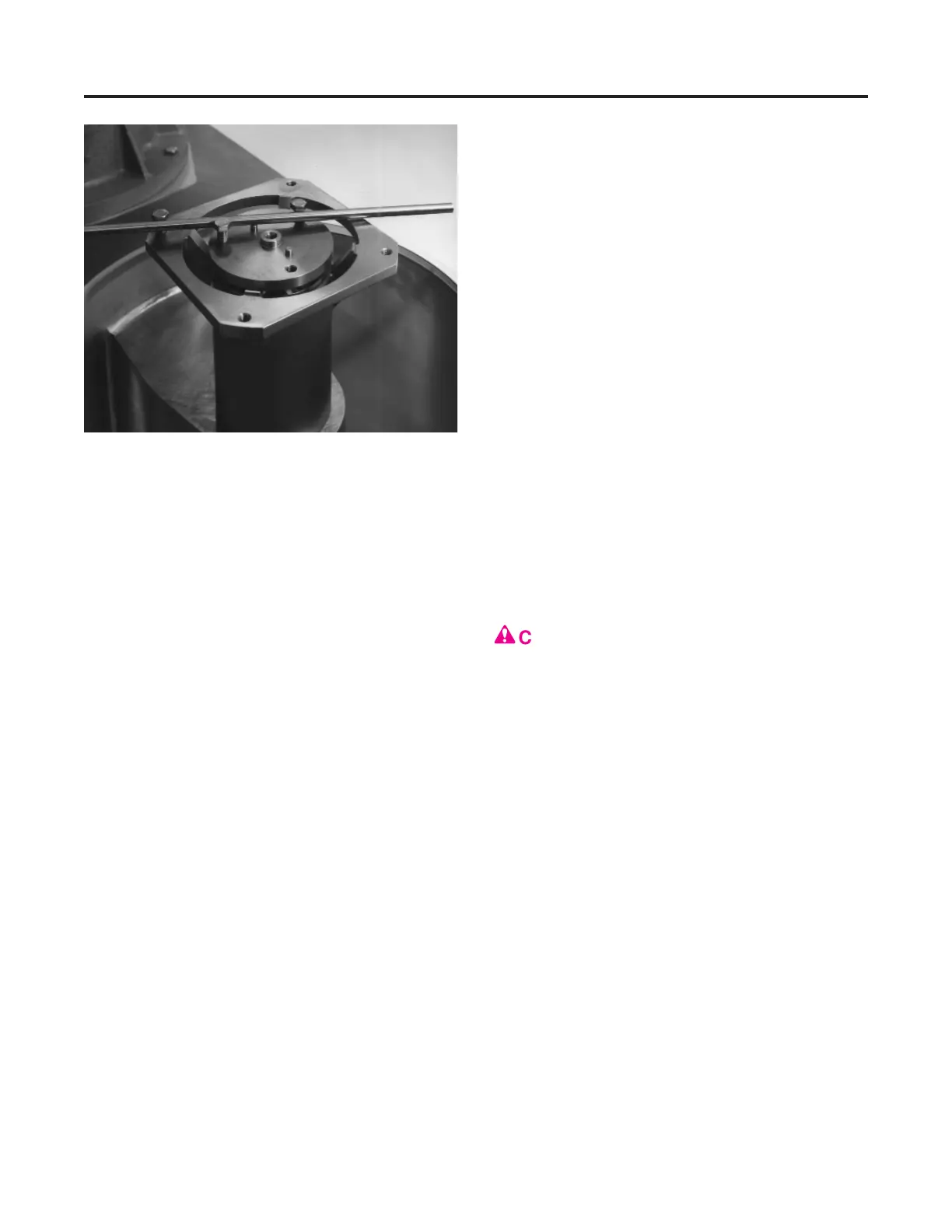

4. Remove spindle pulley. Spindle shaft

must be held stationary to remove spindle

pulley. Insert two 3/8" cap screws into

impeller shaft and one 3/8" cap screw into

spindle flange (Figure 79). Place screw-

driver or bar between screws to prevent

shaft from turning. Remove fastener and

spindle pulley. Motor pulley need not be

removed to change spindle. To remove

motor pulley, engage motor brake (Figure

34, page 46) and remove fastener.

NOTE:

A pulley puller is available if pulleys

prove difficult to remove. Remove flange on

spindle pulley and retainer on motor pulley to

attach puller. See “Tools”, page 82.

At this point drive parts can be inspected or

changed. See “Drive Chart”, page 141, for

appropriate pulleys and timing belt to obtain

desired operating speed. If spindle is to be

removed, see “Removal”, page 54.

w

CAUTION:

Operate machine at recom-

mended speeds only! Operating at other

than recommended speeds could create a

safety hazard and cause excessive wear or

damage to machine parts.

INSPECTION

Timing belt: Belt is reinforced with steel

cables and is almost free from stretch. Inspect

for wear. If timing belt fails during operation,

the steel cables may have separated from belt

and wrapped around impeller shaft above

spindle pulley. If this occurs, check shaft and

seal for damage. The lower bearings in the

spindle assembly should also be inspected for

contamination.

Pulleys and shafts: Remove any nicks or

burrs. Make sure pulley flanges are securely

attached.

MAINTENANCE

Drive Parts

74

Figure 79 — Method to prevent spindle shaft from turn-

ing while removing spindle pulley

Loading...

Loading...