Chapter 6 _______________________________________________________________ Maintenance

VAISALA _______________________________________________________________________ 137

Calibration Procedure Failed

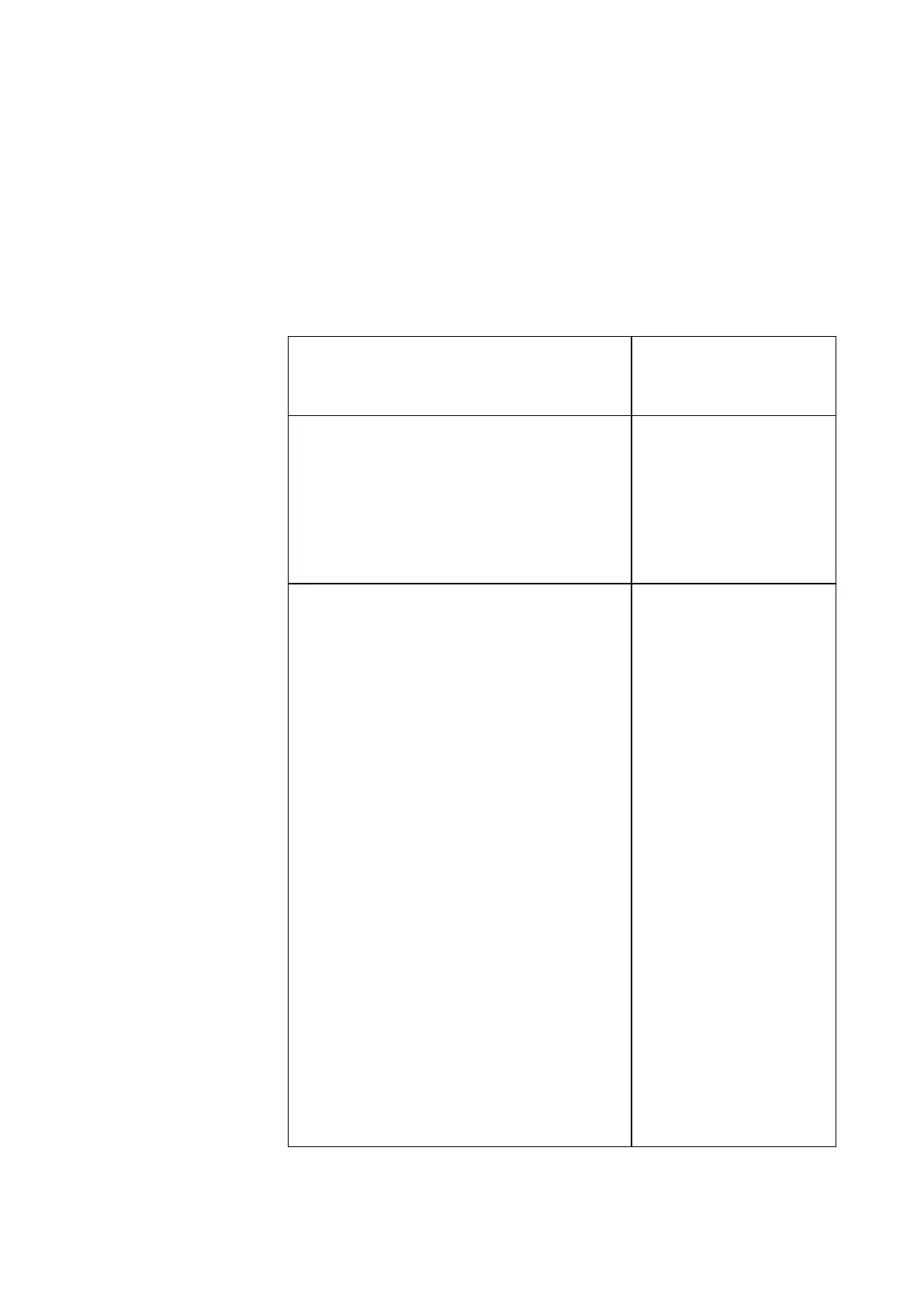

Table 25 below shows an example of a Guided Calibration Procedure

where the Scatter Signal Test (and therefore the Guided Calibration

Procedure) fails due to a too large deviation between calibration values

stored in the measurement unit and the result of the current Calibration

Procedure.

Table 25 Guided Calibration Procedure, Scatter Signal Test

Failed

Step 1/3

Clean Windows and type YES: YES

Install Zero Plugs and type YES:

YES

1st run

.......|||||||||||

Zero signal test PASSED. (0.0000)

Zero Signal Test is passed

successfully.

Remove zero plugs, install glass

plates and

enter signal value (between 0 and

10): .8856

Is signal value 0.885600 correct?

Type YES or NO? YES

1st run

...|||||||||||||||

Signal test FAILED. (1.3497)

Signal change too large. Verify

that glass plates are in place.

Repeat the test? Type YES: YES

2nd run

................||

Signal test FAILED. (1.3497)

Signal change too large. Verify

that glass plates are in place.

Repeat the test? Type YES: YES

3rd run

..................

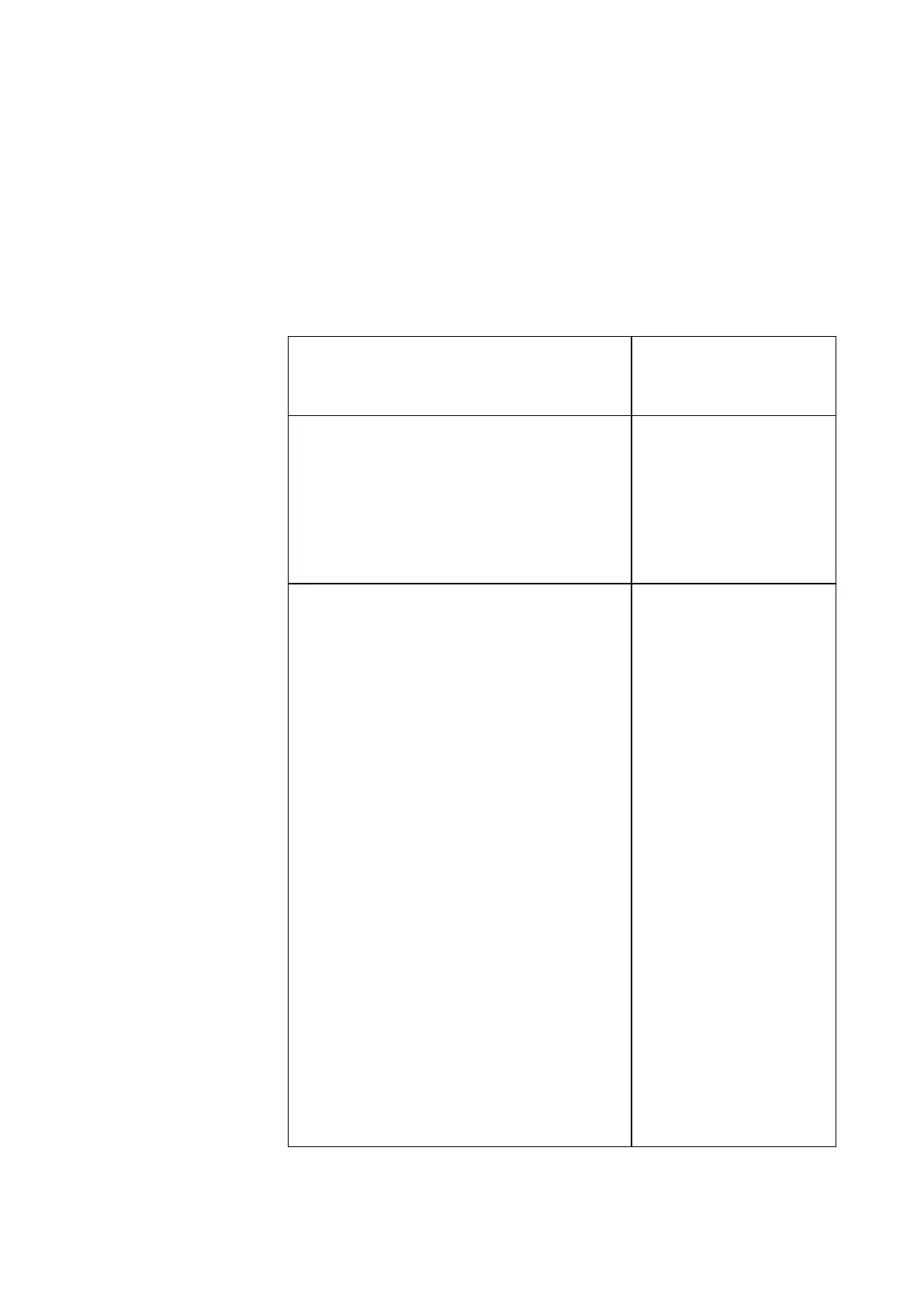

The Scatter Signal Test is

failed three times in a row.

All measured deviations are

off the limit of recalibration.

The most common

handling failure (wrong glass

plate assembly installation) is

mentioned as a hint to

successfully complete the

test.

The user has to confirm

the restart of the test.

Note that an unremoved

zero plug can also create this

failure.

Loading...

Loading...