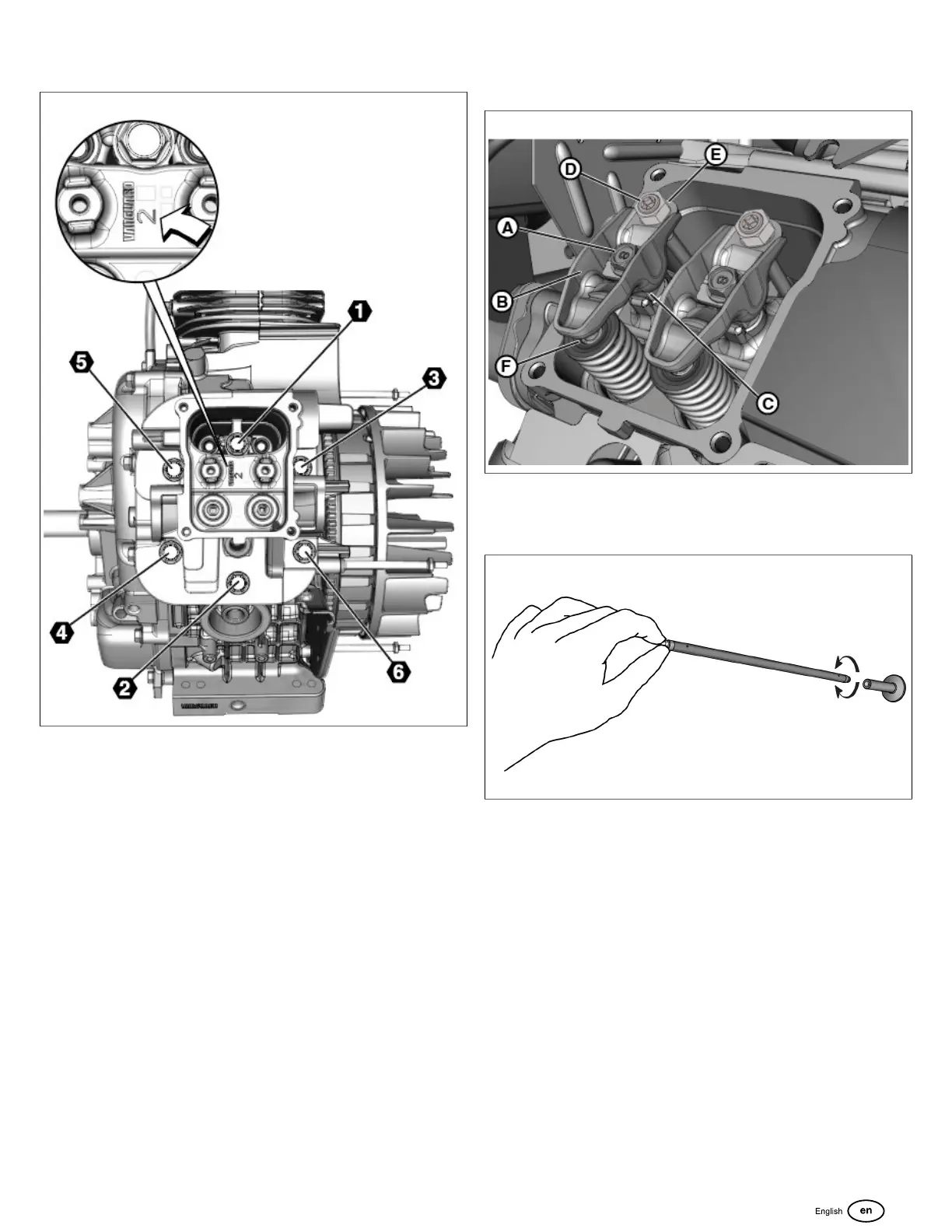

6. Tighten cylinder head bolts in sequence as shown in

Figure 164:

164

A. Tighten bolts to 116lb-in (13.1 Nm) using the

sequence shown.

B. Tighten bolts to 232lb-in (26.2 Nm) using the

sequence shown.

C. Final tighten bolts to 348 lb-in (39.3 Nm) using the

sequence shown.

NOTE: Failure to step-torque cylinder head bolts in the

proper sequence may result in gasket leaks or cause the

cylinder head to warp.

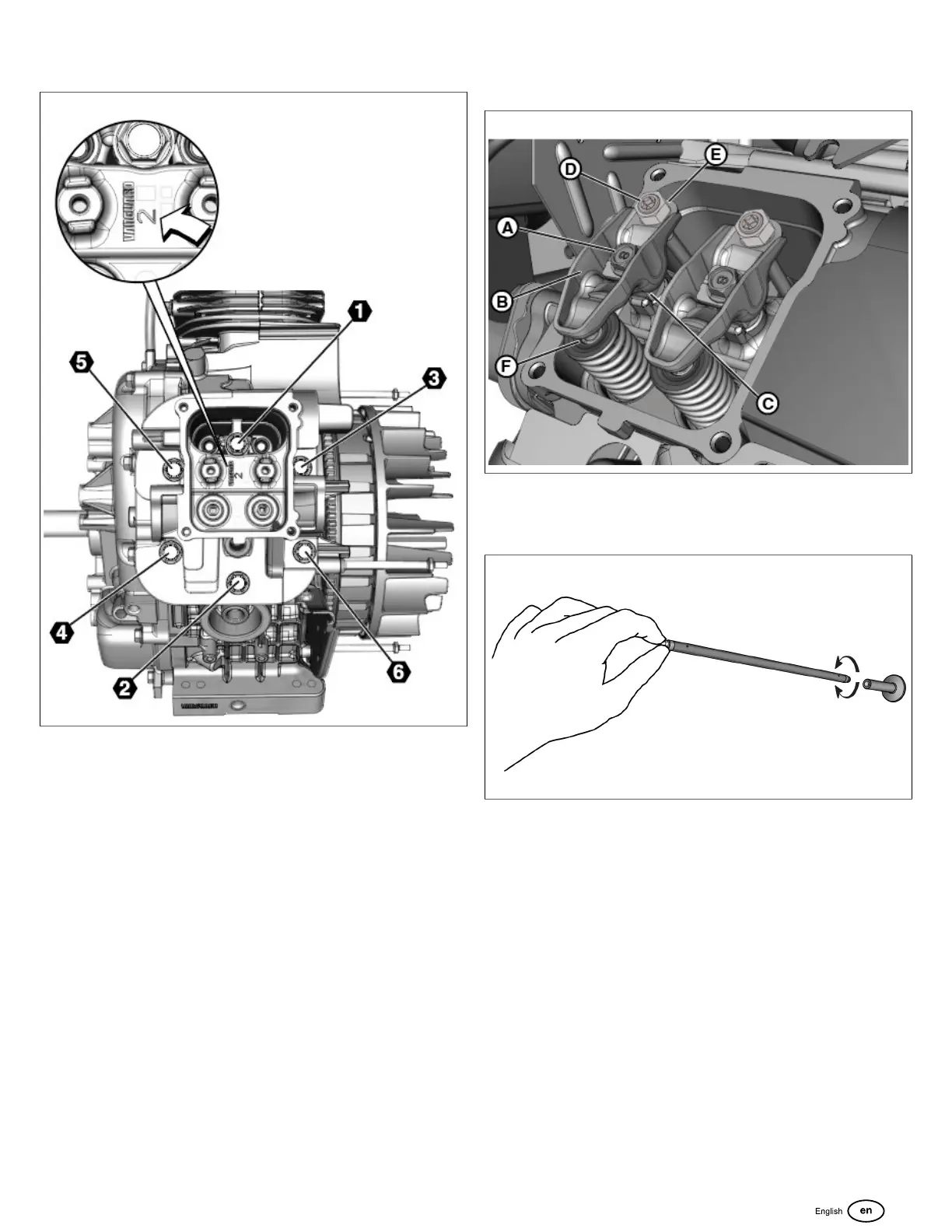

7. Start fasteners (A, Figure 165) to fasten rocker

arms(B)and fulcrums (C) to cylinder head. Tighten

fasteners to 105 lb-in (11.9 Nm).

165

8. Insert push rods into cylinder head bores to engage valve

tappets. Rotate push rods to be sure that ball ends are

seated in valve tappet sockets as shown in Figure 166.

166

9. Install adjuster screws(D, Figure 165)and lock

nuts(E)onto rocker arms.

10. Tightenadjusterscrews to obtain zero clearance

between rocker arms and valve stem tips(F).

Tightenlock nuts until snug.

11. Repeat steps 7-10 on opposite cylinder.

12. Slowly rotate crankshaft to verify proper movement of

push rods and rocker arms.

13. Adjust valve clearance. See SECTION 2 -

MAINTENANCE, CHECK/ADJUST VALVE

CLEARANCE.

14. Slowly rotate crankshaft 3 full turns to seat valve train.

15. Recheck valve clearance and adjust if necessary.

16. Verify that mating surfaces of cylinder heads and valve

covers are clean and dry. Any dust or dirt left on mating

surfaces can cause leaks.

17. Install new valve cover gaskets onto valve covers.

127

Loading...

Loading...