104

Before adjusting the wheel alignment angles check the fol-

lowing:

- pressure in tyres;

- axial gap in front wheel hub bearings;

- serviceability of shock-absorbers (absence of rod jamming);

- radial and axial runout of tyres;

- gap in suspension balljoints;

- free play of steering wheel.

Rectify any detected malfunctions and make necessary

adjustments.

After placing the vehicle on a test-bench, immediately prior to

inspection, apply 2 or 3 times a downward force of 392-490 N

(40-50 kgf) first on the rear bumper and then on the front one.

The wheel alignment angle should be checked and adjusted

in the following sequence:

1. Caster angle

2. Camber angle

3. Toe-in

Caster angle. If the check will show that the angle size does

not correspond to the above data, it is necessary to change the

quantity of adjusting washers 50 (see fig. 4-1) between the upper

arm shaft and the crossmember arm (see tab. 4-2).

Table 4-2

Camber and caster angle vs. number of washers in a set

Number of washers added

to the set or withdrawn camber caster

front bolt rear bolt

+1 +1 + (8' 42'') 0

-1 -1 - (8' 42'') 0

+1 0 - (7' 30'') + (20' 24'')

-1 0 + (7' 30'') - (20' 24'')

0 +1 + (15' 18'') - (25' 18'')

0 -1 - (15' 18'') + (25' 18'')

-1 +1 + (27' 30'') - (43' 18'')

+1 -1 - (21' 36'') + (40')

Note. Data are given for washers with thickness of 0.75 mm.

Plus - adding a washer, minus - removing a washer.

To adjust the caster angle:

- undo the fastening nuts of the front suspension upper arm

shaft and replace the washers from one bolt to the other one until

a normal reading of the angle will be obtained. The caster angle

increases at rearrangement of washers from the rear bolt to the

front one and decreases at reverse swapping;

- tighten the nuts with a torque wrench and check the caster

angle.

Front wheel camber. If the camber angle differs from nor-

mal, it should be adjusted by changing the amount of washers 50

(see fig. 4-1) between the upper arm shaft and crossmember

bracket.

To reduce the camber angle remove the same amount of

washers from both bolts, and to increase - add.

Front wheel toe-in. If the toe-in differs from normal value, it

is necessary to slacken the fastening clamps on the side tie-rods

and using tool 67.7813.9504 identically turn both adjuster pins in

opposite directions; thus the pins are turned on or off and change

the length of side tie-rods.

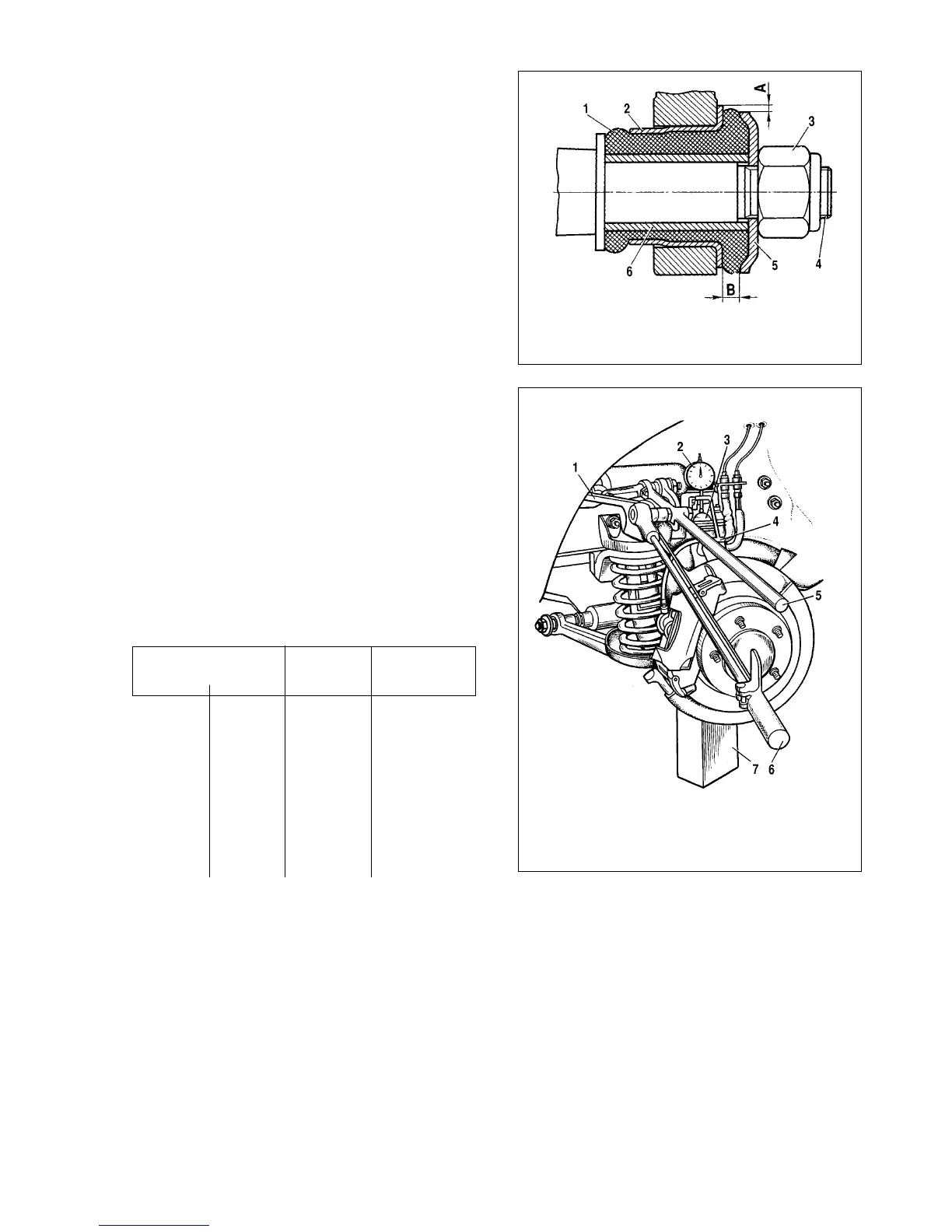

Fig. 4-2. Inspection of the front suspension arm silent block:

1 - rubber bush; 2 - outer bush; 3 - shaft securing nut; 4 - suspension arm shaft;

5 - thrust washer; 6 - inner bush

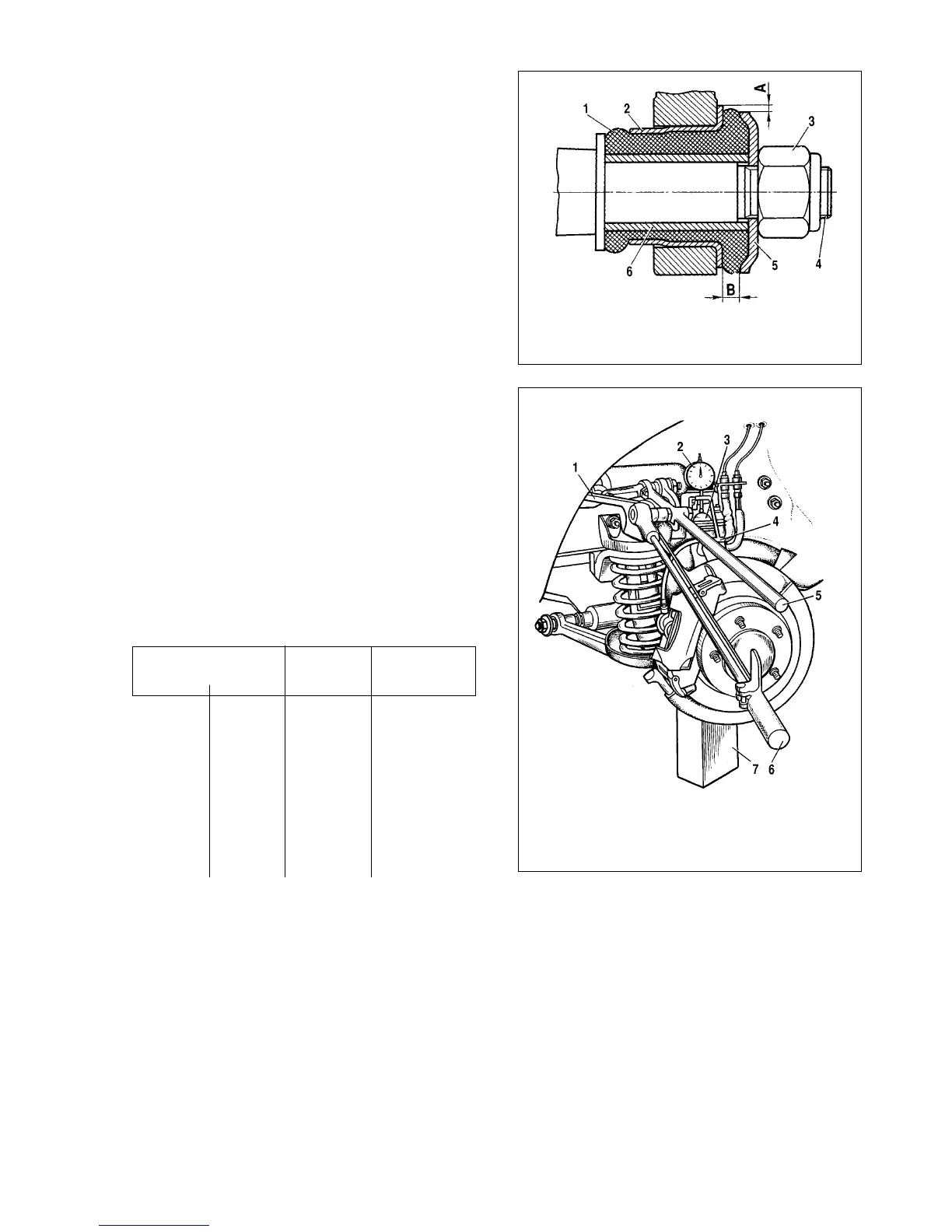

Fig. 4-3. On-vehicle check of the clearance in the suspension upper

balljoint:

1 - upper control arm; 2 - indicator; 3 - upper balljoint housing; 4 - indicator fas-

tening bracket; 5 - control arm; 6 - dynamometer; 7 - block

Loading...

Loading...