- position the vehicle on a lift, dismantle all relevant compo-

nents and trims which may obstruct access to box sections;

- through provisional or drain holes flush inner cavities and

the underbody with warm (40-50°ë) water (Table 8-2) until the

drained water is clean. Do not forget to fully close the windows;

- remove any water penetrated into the passenger or lug-

gage compartments; blow dry with compressed air the areas

where rust inhibitors are going to be applied;

- drive the vehicle into a corrosion treatment booth and posi-

tion it on a lift; spray the relevant rust inhibitor onto the areas

shown in Fig.8-6, Fig.8-7 and Fig.8-8;

- lower the vehicle, wipe off any dirt from the outside body

surfaces with a cloth moistened in white spirit.

Restoring corrosion-proof and sound-proof coat-

ing on underbody and wheel arches

When in service, the vehicle underbody is deteriorated by

loose gravel, sand salt and water.

As a result, undersealant and primer can be damaged and

worn thus encouraging rust.

For the purposes of noise reduction, corrosion protection and

wear resistance, the underbody and chassis arms are factory

treated with PVC plasticate - Plastisol Ñ-11Ä»- of 1-1.5 mm thick-

ness over epoxy ùî-083 primer.

174

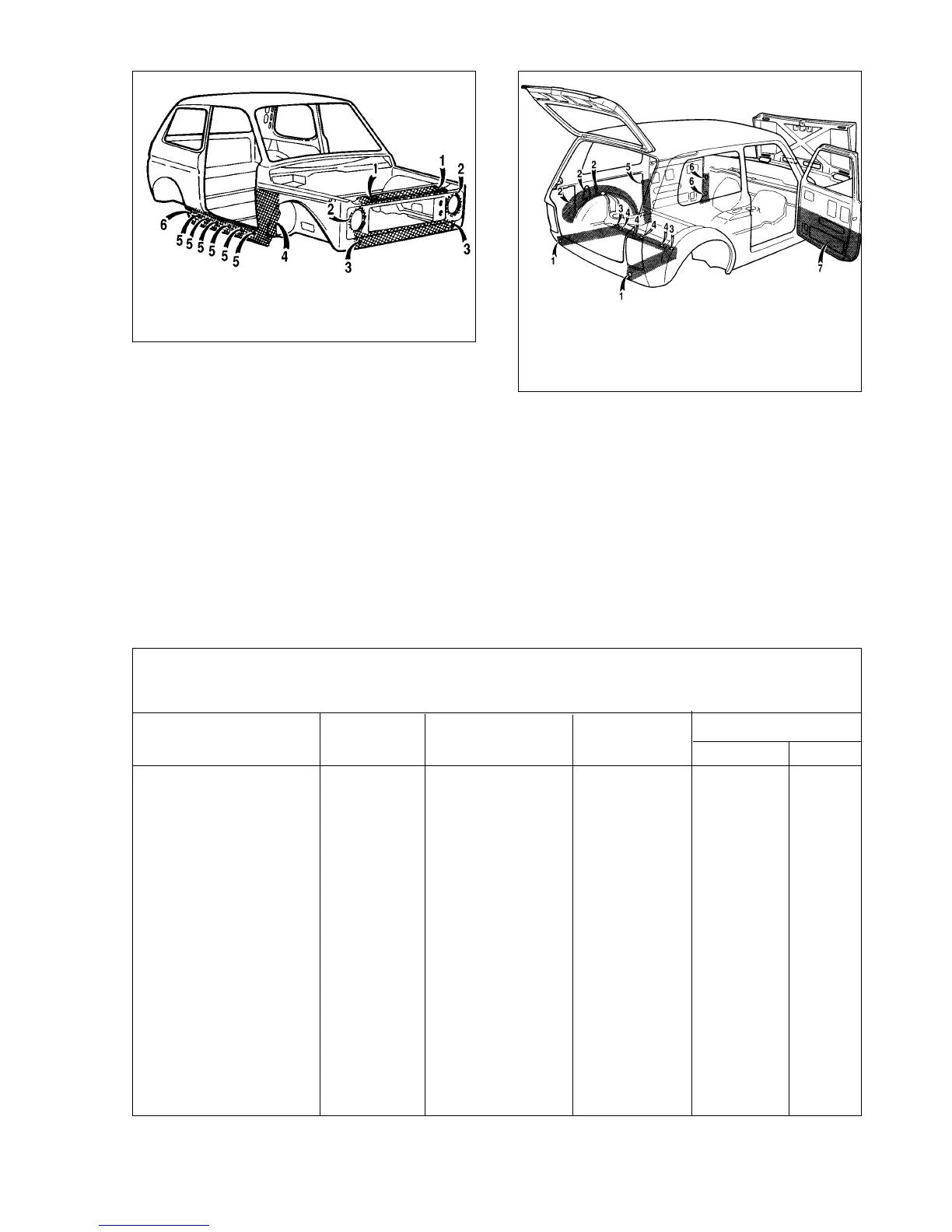

Fig.8-7. Rear view of the body. Inner cavities of:

1 - rear chassis arms; 2 - between rear wheel arches and body sides; 3 - rear

chassis arms; 4 - rear floor cross-member; 5 - central pillars; 6 - front door pil-

lars; 7 - door pocket

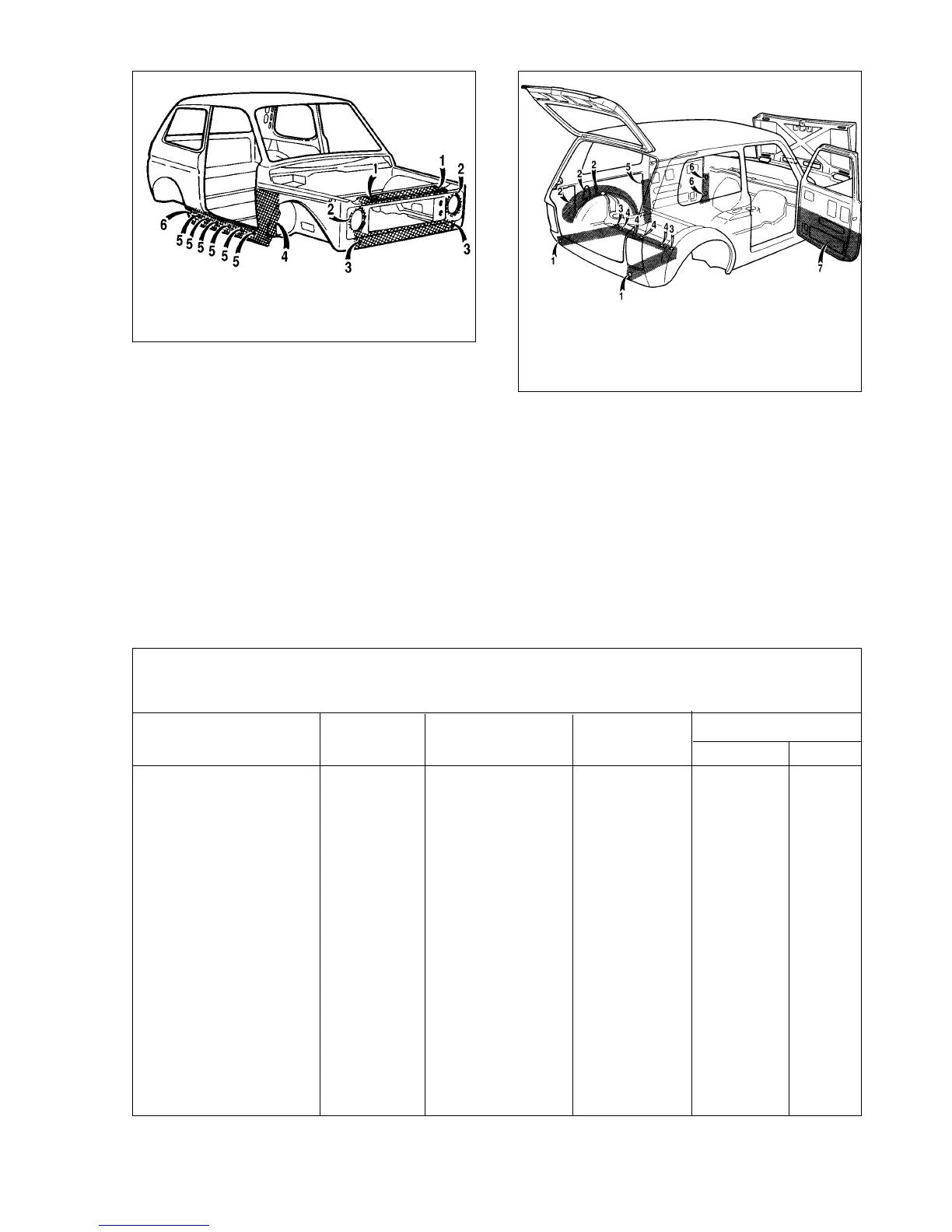

Fig.8-6. Front view of the body. Inner cavities of:

1 - top front cross-member; 2 - headlight casings; 3 - bottom front cross-mem-

ber; 4 - under front wing; 5 - outer sill; 6 - inner sill

퇷Îˈ‡ 8-1

Corrosion inhibitors for bodywork protection

Description Grade Viscosity, sec Solvent, thinner Drying conditions

at 20 °ë as per Çá-4 Temperature, °ë Time, min

Automotive sill rust inhibitor åÓ‚Ëθ

åÓ‚Ëθ-2 15 - 40 white-spirit, petrol 20 20 - 30

Protective non-drying grease çÉå-åã 45 white-spirit 20 15

Protective skin çÉ-216Å 18 - 22 white-spirit, petrol 20 20

Bitumen-type sound-proof sealant Ååè-1 high viscosity ksylol, solvent 100-110 30

PVC plasticate Plastisol Ñ-11Ä Detto – 130 30

Plasticate Plastisol Ñ-4Ä Detto – 130 30

Non-drying sealant 51-É-7 Detto – –

Loading...

Loading...