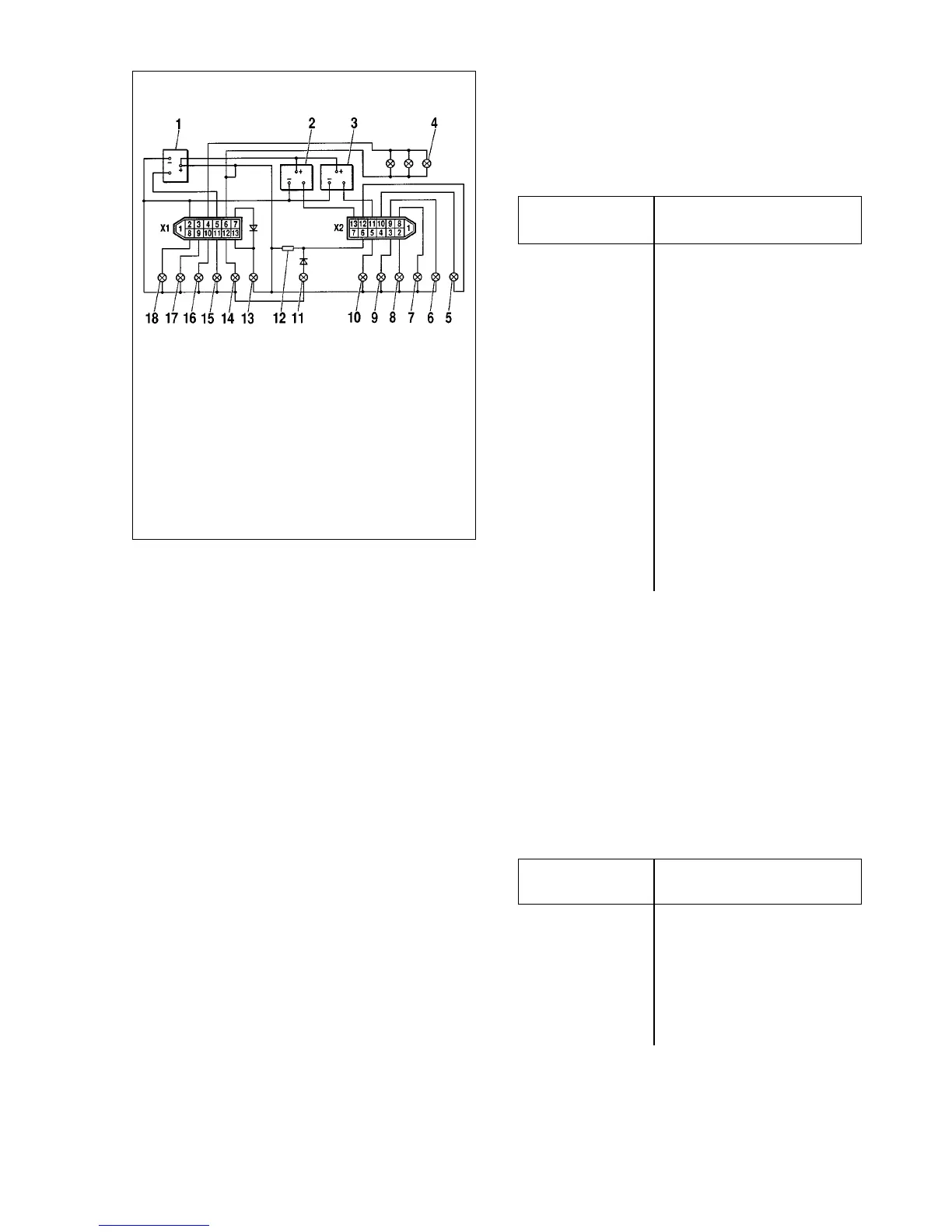

Connector ï2 (any colour, except red and amber)

1 -

2 To high beam relay

3 To exterior lighting switch

4 -

5 To indicators flasher relay

6 To alternator terminal «Ç»

7 -

8 To rear foglight switch

9 To heated rear window switch

10 To ignition switch terminal «15»

11 To fuel level sensor terminal «T»

12 To coolant temperature sender

13 To coolant temperature sender

Coolant temperature gauge - Òhecking. The coolant tem-

perature gauge is associated with the relevant sender in the

cylinder head. At the sensor resistance of 640-1320 Ohm the

needle should be at the low end of scale, at 77-89 éhm it should

rest at the front of the red area, at resistance of 40-50 Ohm the

needle should go to the end of the red area.

Fuel level gauge - Òhecking. The fuel gauge is associated

with the relevant sensor in the petrol tank. The same sensor

operates the fuel reserve warning light, when 4 to 6 litres are left

in the petrol tank. At the sensor resistance of 200-238 Ohm the

needle should at the low end of scale, at 59-71 Ohm - at the mid-

dle scale, while at 17-23 Ohm the needle should go to the high

end of scale (mark 1).

Speedometer - checking. Check the speedometer turning

its drive shaft at various speeds. The data required for checking

is shown in Fig.9-4.

Table 9-4

Speedometer specification

Speedometer Drive shaft

readings, km/h speed, rpm

30 433 - 500

40 600 - 667

50 766 - 833

60 933 - 1000

80 1250 - 1333

100 1567 - 1667

120 1883 - 2000

140 2200 - 2333

160 2517 - 2667

Tachometer - checking. The tachometer operates on the

principle of measuring the voltage pulse frequency in the alter-

nator field winding.

The tachometer is checked on a test bench simulating the

vehicle ignition system. Connect the tachometer as applicable,

apply 14 volts to the primary circuit and set the spark gap at 7

mm. Turn the ignition distributor shaft at such a speed to bring

the tachometer needle to one of main scale divisions. At this

moment the ignition distributor shaft speed should be within the

permissible limits (Refer to Table 9-5).

Table 9-5

Tachometer specification

Tachometer Ignition distributor

reading, rpm shaft speed, rpm

1000 900 - 1100

2000 1900 - 2250

3000 2950 - 3300

4000 3950 - 4300

Fuel level sender - checking. With an empty tank the sen-

sor resistance should be (250±10) Ohm, with a half-filled tank -

(66±6) Ohm, with a full tank - (20±2) Ohm.

208

Fig.9-36. Wiring diagram for instrument cluster:

1 - digital tachometer; 2 - coolant temperature gauge; 3 - fuel level gauge; 4 -

instrument illumination light; 5 - engine overheating warning light; 6 - heated

rear window warning light; 7 - rear fog light warning light; 8 - high beam warn-

ing light; 9 - exterior lighting warning light; 10 - direction indicator warning light;

11 - low battery warning light; 12 - resistor, 50 éhm, 5 W; 13 - brake failure

warning light; 14 - low oil pressure warning light; 15 - differential lock-up warn-

ing light; 16 - fuel reserve warning light; 17 - seat belt reminder; 18 - handbrake-

on warning light Connector «ï1» is red or orange

Loading...

Loading...