Vertiv™ | Liebert® SRC-G | User Manual

27

Mechanical Installation

2.8.1. Quick Thread Connector Installation Notes

Refer the following procedure when connecting the quick thread connector:

1. Remove dust-proof caps

2. Carefully clean the coupling seats and threaded surface of the connector with a clean cloth

3. Lubricate the male thread with lubricant oil

4. Thread the coupling halves together by hand to ensure that the threads mate properly

5. Tighten the coupling body’s hexagon nut and union valve until a definite resistance is felt

6. Use a marking pen to draw a line lengthwise from the coupling union nut to the bulkhead. Tighten the nuts an

additional quarter turn with two wrenches

7. The misalignment of the lines shows how much the coupling has been tightened

• Care must be taken while performing this operation to avoid any damage to the connector threading.

• Two wrenches must be used to cooperate with each other during connection, because one wrench can

damage the coupling copper lines easily.

The recommended torque values are listed in Table 2-10.

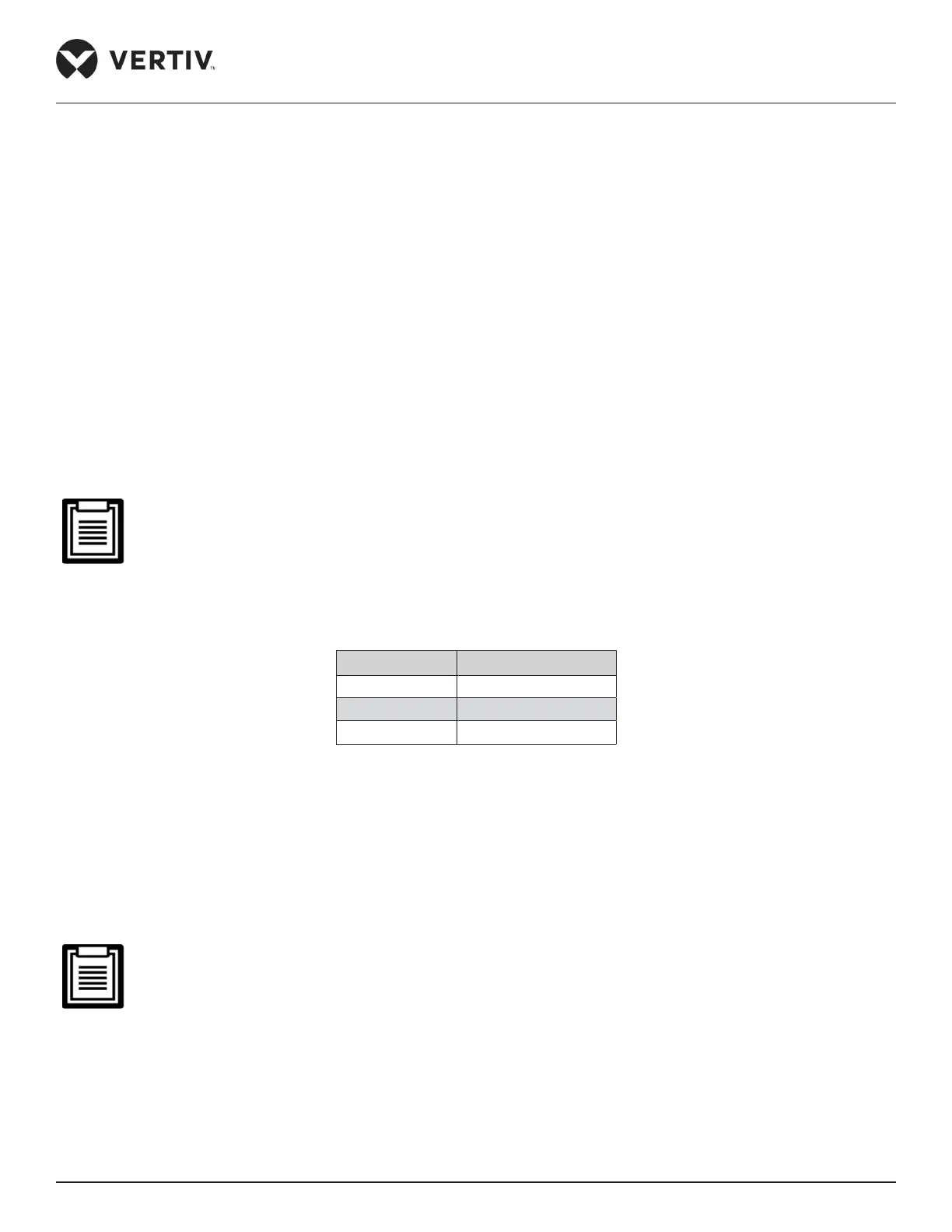

Table 2-10 Recommended Torque Value

Coupling Size Torque Value (N.m)

5/8” 7 to 8

1/2” 15 to 18

3/4”, 7/8” 25 to 32

2.8.2. Piping Connection Requirements

Refer to Figure 2-2 and Figure 2-3; the required piping connections are as follows:

• Refrigerant piping between the indoor and the outdoor units (gas and liquid piping).

• Drain piping connections of the indoor unit.

Prior to start-up, ensure that all piping connections have been completed and there is no leakage in the

system.

Loading...

Loading...