■ Expected steam volume, taking account of the static head of the

system

■ Pre-charge pressure

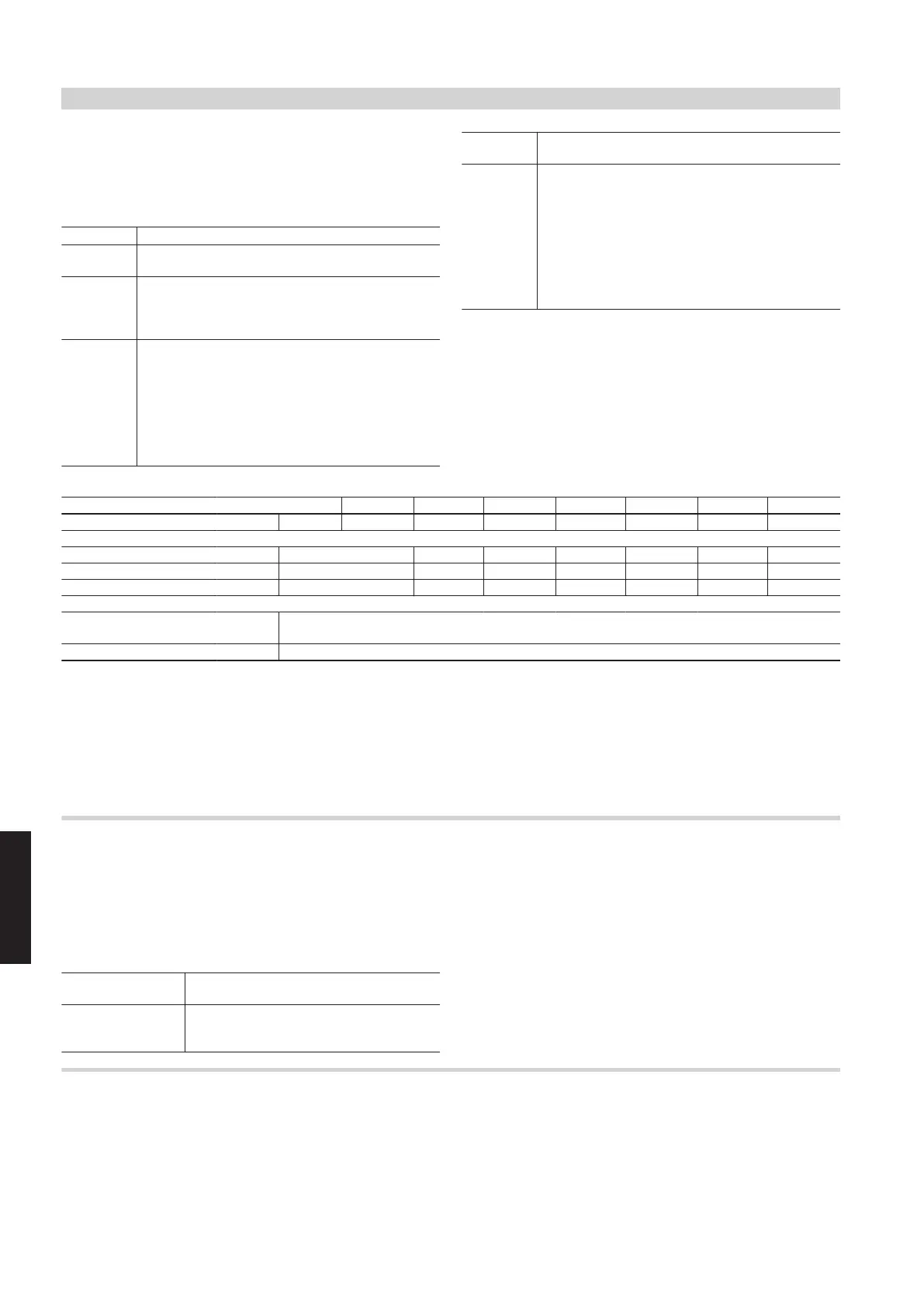

V

dev

= (V

col

+ V

dpipe

+ V

e

+ V

fv

)·Df

V

dev

Nominal volume of the expansion vessel in l

V

col

Liquid content of the collectors in l

In systems with Vitosol-FM/300-TM this value = 0

V

dpipe

Content of the pipework subject to steam loads in l

(Calculated from the steam spread and the pipework

content per m pipe length)

In systems with Vitosol-FM/300-TM this value = 0

V

e

Increase in the volume of the heat transfer medium in

its liquid state in l

V

e

= V

a

· β

V

a

System volume (content of the collectors, the

heat exchanger and the pipework)

β Expansion factor

β = 0.1 to 0.13 for Viessmann heat transfer medi-

um

V

fv

Liquid seal in the expansion vessel in l

(4 % of the system volume, min. 3 l)

Df Pressure factor

(p

e

+ 1) : (p

e

− p

o

)

p

e

Max. system pressure at the safety valve in bar

(90 % of the safety valve response pressure)

p

o

System pre-charge pressure

– Vitosol 200-TM/Vitosol F:

p

o

= 1 bar + 0.1 bar/m static head

– Vitosol-FM/Vitosol 300-TM:

p

o

= 3 bar + 0.1 bar/m static head

To determine the system and steam volume in the pipework, the content per m of pipe must be taken into consideration.

Vitotrans 200, type WTT Part no. 3003 453 3003 454 3003 455 3003 456 3003 457 3003 458 3003 459

Capacity l 4 9 13 16 34 43 61

Copper pipe Dim. 12 x 1 15 x 1 18 x 1 22 x 1 28 x 1.5 35 x 1.5 42 x 1.5

DN10 DN13 DN16 DN20 DN25 DN32 DN40

Capacity l/m pipe 0.079 0.133 0.201 0.314 0.491 0.804 1.195

Corrugated stainless

steel pipe

Dim. DN 16

Capacity l/m pipe 0.25

For the liquid content of the following components see the relevant

"Specification" chapter:

■ Collectors

■ Solar-Divicon and solar pump assembly

■ DHW cylinder and heating water buffer cylinder

Note

Check the size of the expansion vessel on site.

Calculation with "Solsec" design program

The "Solsec" program is available at www.viessmann.com for calcu-

lating the residual cooling capacity and sizing the expansion vessels.

Safety valve

The heat transfer medium is drained from the solar thermal system

via the safety valve if the max. permissible system pressure is

exceeded. According to DIN 3320, the response pressure of the

safety valve is the max. system pressure +10 %.

The safety valve must comply with EN 12975 and EN 12977, be

matched to the heating output of the collectors and be able to handle

their maximum output of 900 W/m

2

.

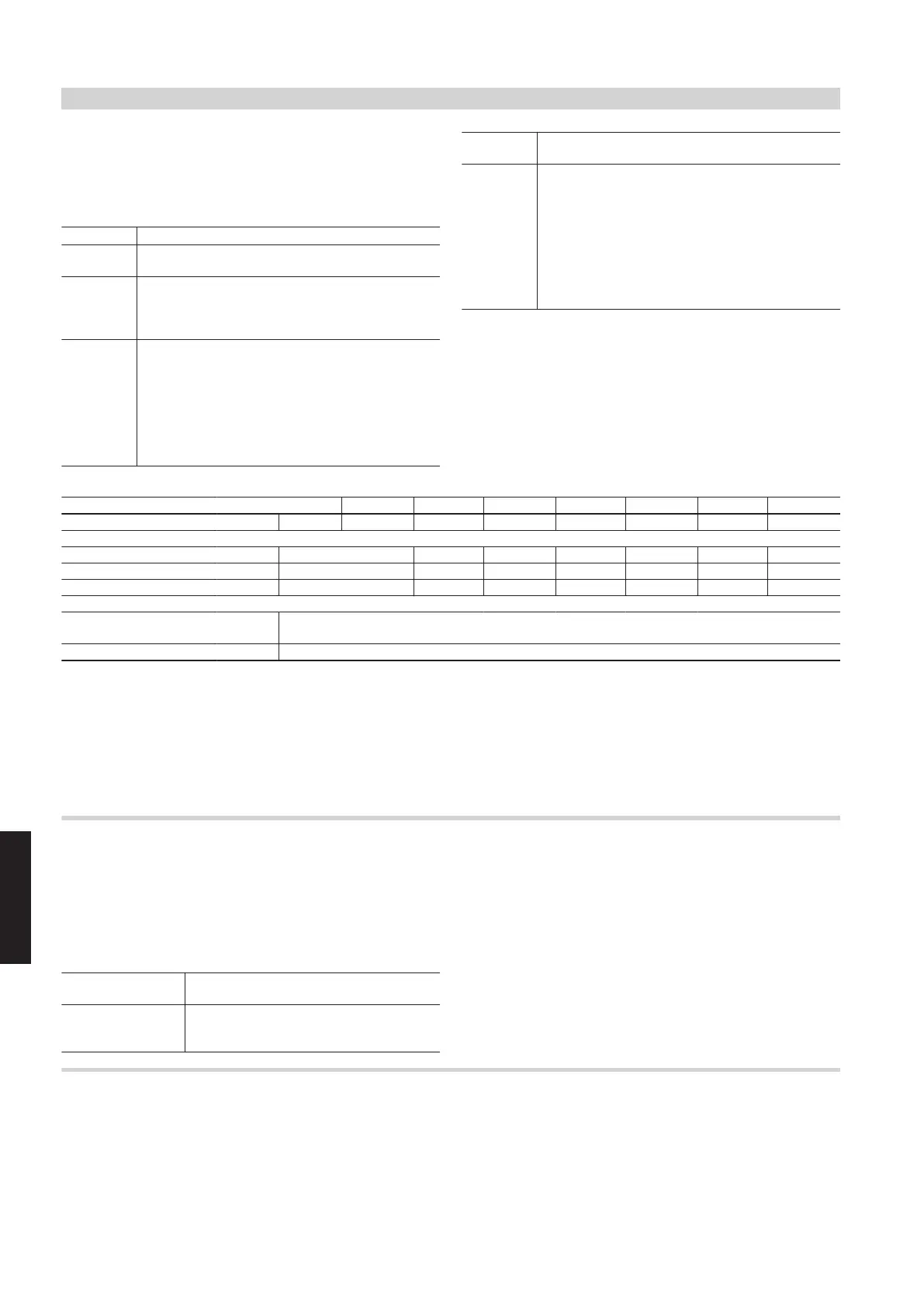

Absorber area in m

2

Valve size (size of the inlet cross-section)

DN

40 15

80 20

160 25

Discharge and drain lines must terminate in an open container,

capable of collecting the total content of the collectors.

Viessmann Solar-Divicons are equipped with 6 bar safety valves at

the factory. In solar thermal systems equipped with switching collec-

tors, the 6 bar safety valves fitted at the factory can be replaced with

8 bar valves. See accessories, page 86.

High limit safety cut-out

The solar control units Vitosolic 100 and 200 are equipped with an

electronic temperature limiter.

A high limit safety cut-out in the cylinder is required when less than

40 l cylinder capacity is available per m

2

absorber area. This reliably

prevents temperatures above 95 °C in the cylinder.

Example:

■

3 Vitosol-F flat-plate collectors, 7 m

2

absorber area

■ DHW cylinder with 300 l capacity

■

300 : 7 = 42.8 l/m

2

A high limit safety cut-out is not required.

Information regarding design and operation

(cont.)

136

VIESMANN

VITOSOL

13

5822 440 GB

Loading...

Loading...