53

PEA-C4XL-S

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC2345334

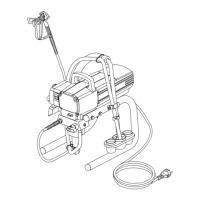

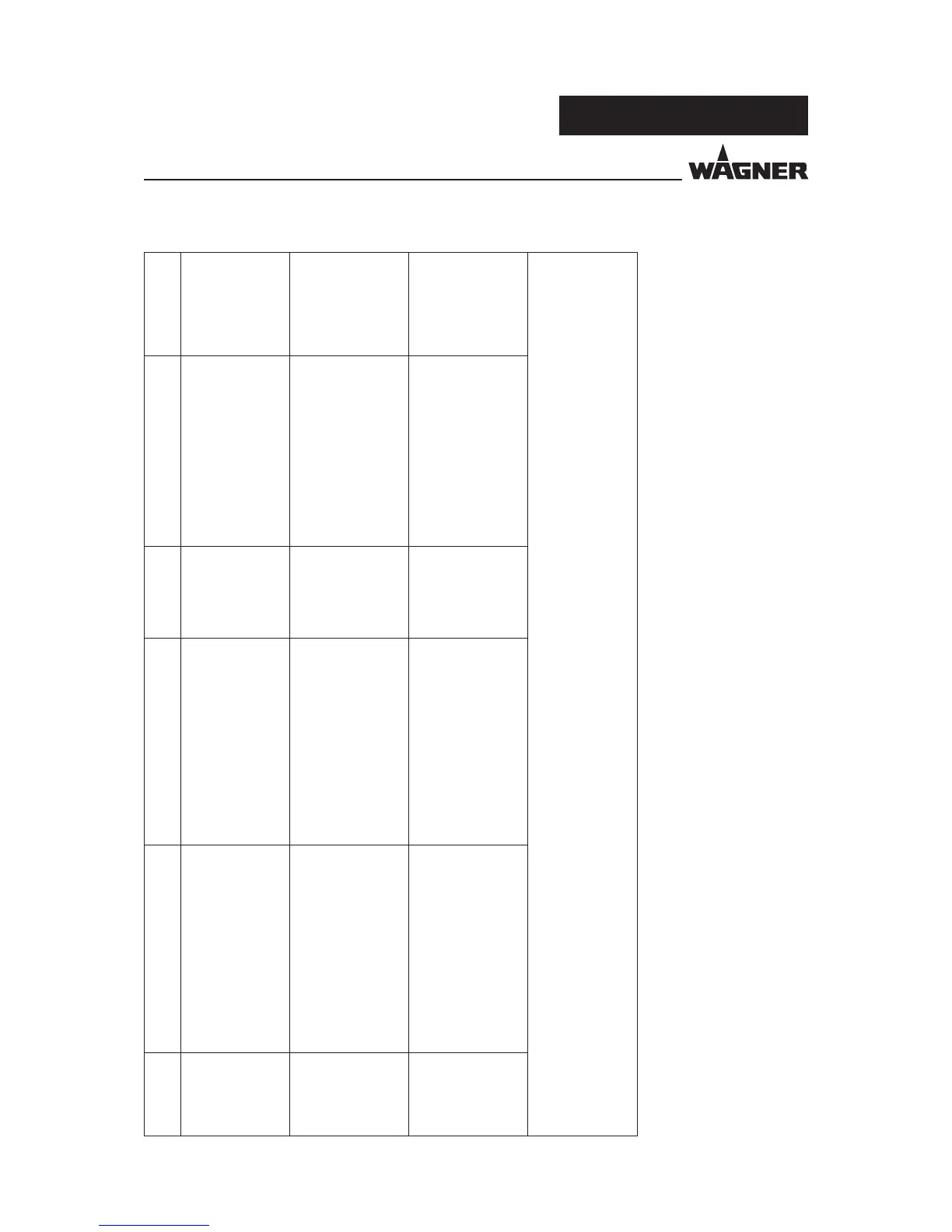

Section Type of inspection Requirements Inspection

by

Type of inspection Inspection

interval

1E ectiveness of technical

ventilation check

E ectiveness of technical

ventilation check

TP/SP ME

e.g. measurements of air ow

speed / air quantities,

checking of the di erential

pressure indicator according

to the cabin manufacturer's

instructions

continuously

according to

the booth

manufacturer's

instructions

2 Interlock between technical

ventilation and high-voltage,

compressed air and coating

product supply

The technical ventilation should

be interlocked such that the high-

voltage cannot be switched on

while the technical ventilation is

not working e ectively.

SP FI

Test whether the system is safely

stopped and the product supply,

supply air and high-voltage

are switched o when the

ventilation is shut down.

annually

3 Protection against ignition of

ammable cleaning agents

If ammable cleaning uids are

used, all parts carrying high-

voltage must be discharged to a

discharge energy of less than

0.24 mJ, once the high-voltage has

been switched o , before they can

be reached.

SP ME/FI

Function test of the residual

energy monitoring equipment

according to the manufacturer's

instructions.

according to the

manufacturer's

instructions

Legend:

MA = Manufacturer

EM = Employer

SP = Skilled person

FSE = Fire safety engineer

ELC = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

SI = Standard inspection

VI = Visual inspection

CI = Continuous inspection

TI = Technical inspection

9.1 OVERVIEW OF INSPECTIONS

Loading...

Loading...