84

wallaceperimetersecurity.comPhone: 866.300.1110

INSTALLATION INSTRUCTIONS FOR OPTIONAL VEHICLE DETECTORS

Installaon of Vehicle Detecon Ground-Loop Systems

8. If an automac exit loop is required, a third detector relay will be required. If an automac

exit loop is required, a third detector relay will be required (not supplied by Wallace Perimeter

Security). This auxiliary detector should be powered from terminals #1 and #2 and wired as a

N.O. contact to terminals #1 and #3.

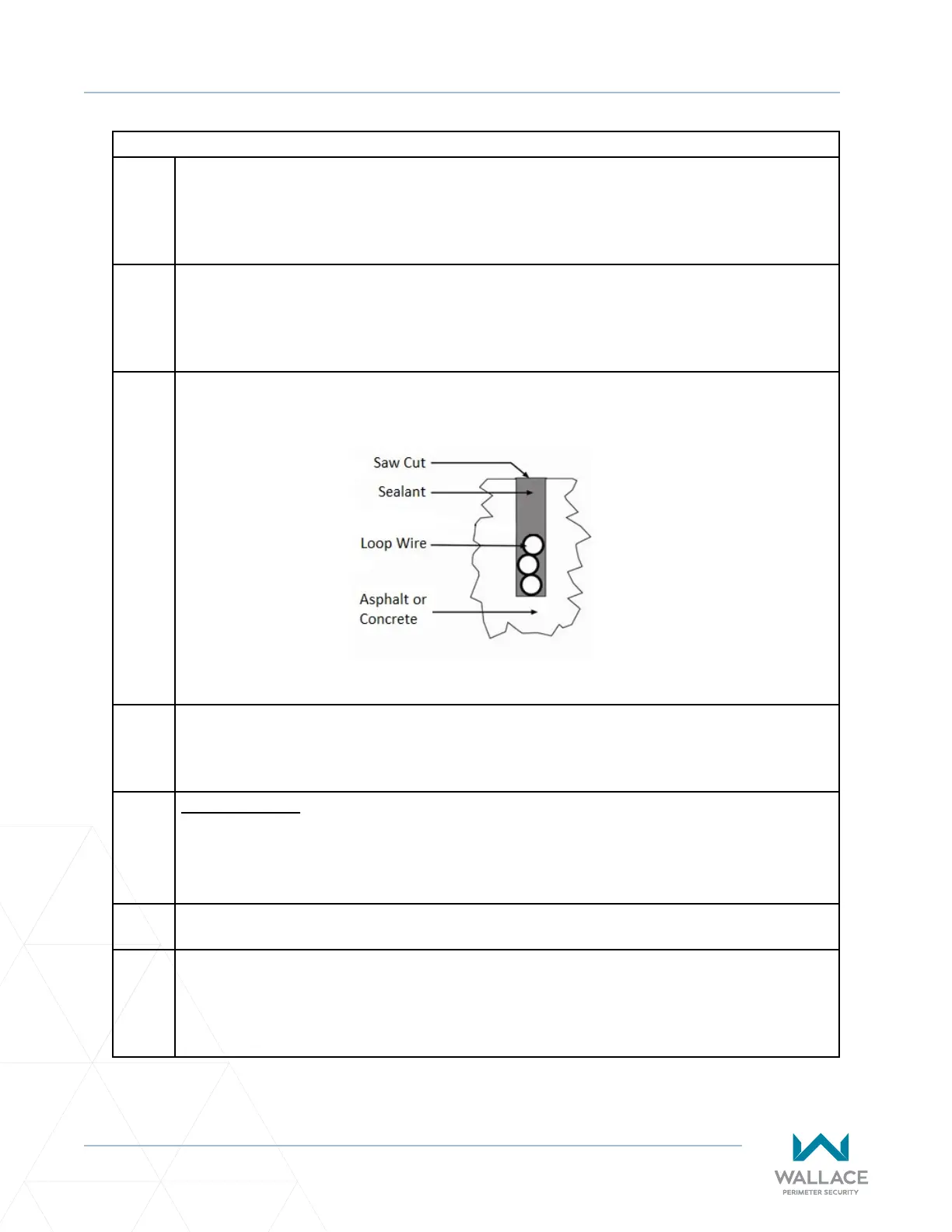

9. Choose a sealant carefully to match the applicaon and the pavement type. Hard seng

epoxies should not be used with asphalt. Cauon should be observed when using hot sealants,

as high temperatures can damage or destroy wire insulaon. Please refer to the jurisdicon/

state’s department of transportaon specs for trac light loop sealant.

9.1 When properly applied, the sealant should completely cover the loop wire(s). Since the sealant

forms a barrier between the wire and the environment, it is essenal that the wire(s) are

completely covered. See Figure 20 for the proper end result.

9.2 There MUST be no voids which might allow water to collect within the slot. The water will

freeze and expand during freezing condions. Freeze/thaw cycling will eventually push the

loop wires up and out of the slot, resulng in a loop failure.

10.

Loop Diagnoscs

The following tests cannot guarantee a funconing loop, but failure of either test means that

the loops are denitely suspect, even if sll funconal at the me of tesng.

10.1 TEST 1 - Resistance of the loop and loop lead wires should not exceed 4.0 ohms.

10.2 TEST 2 - The resistance to earth, as measured with a 500V “Megger”, should be 100 Megohms

or more. Loops may funcon at less than 100 Megohms but will not be reliable (e.g., when the

ground is wet from rainfall). Low resistance indicates broken or moisture-saturated insulaon.

This is common if inappropriate wire insulaon has been used.

Figure 20. Proper Sealant Applicaon

Loading...

Loading...