SPEEDGATE Installation and Maintenance Manual Revision 1 - MAY 2023

9

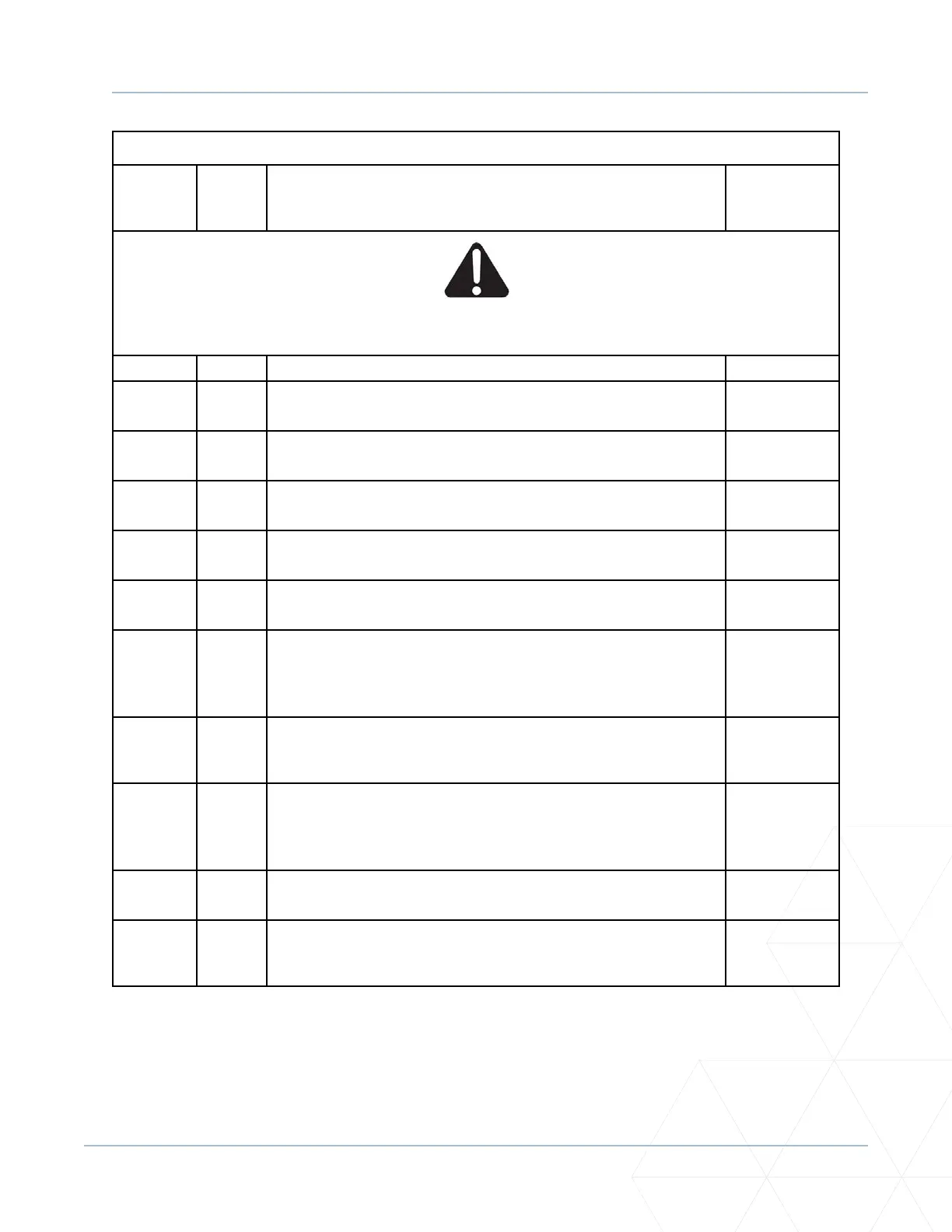

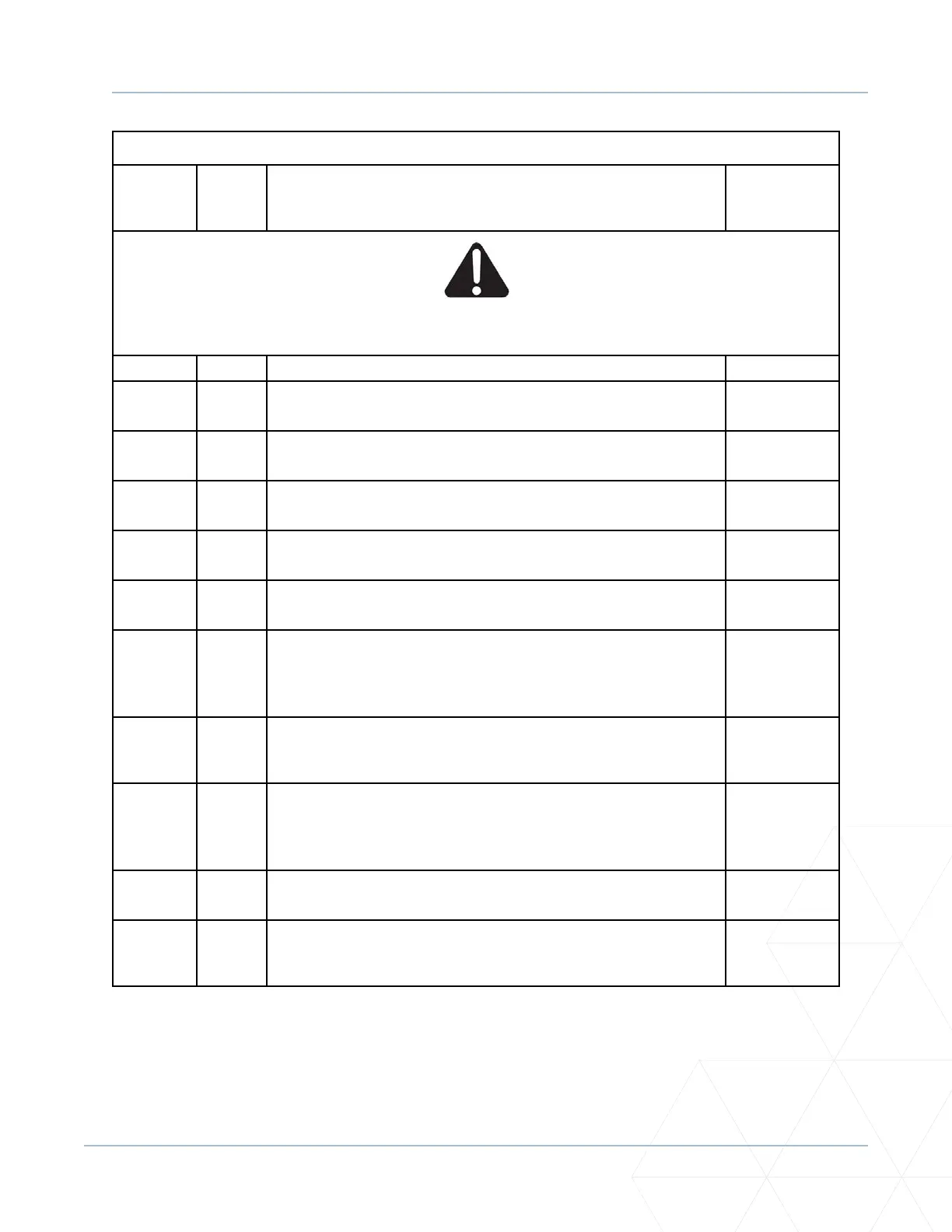

INSTALLATION AND COMMISSIONING CHECKLIST

Installaon and Commissioning Checklist

Complete Step Descripon Manual

Secon

Reference(s)

The SpeedGate should only be operated by persons that were onsite for the nal gate commissioning.

5.1 CHECK BEFORE POWERING UP THE OPERATOR:

5.1.1 All fasteners for proper tension: --

5.1.1-A. Hinge bolts at 85 -lbs (115.26 N m) --

5.1.1-B. Drive pin bolts at 90 -lbs (122.02 N m) --

5.1.1-C. Security bolts, which secure the drive housing should be ½ a turn

past hand ght.

--

5.1.1-D. All anchor bolts ghtened to 210 -lbs (284.76 N m) --

5.1.2 Safety devices for proper wire terminaon (photo eyes, sensing

edges, loop detectors).

page 70

page 73

page 75

page 80

5.1.3 All wiring secure in wiring loops in motor drive housing, no

straining at motor drive housing/column connecon, no wires

near drive mechanisms.

--

5.1.4 Grease rod end bearings (drive linkage) and all gate hinges with

lithium grease or synthec grease (as provided). Recommended

lubricant:

Castrol Pyroplex® Protecon ES

--

5.1.5 Drive housing covers have been re-installed. --

5.1.6 Ensure any tools shipped with the gate (tamper-resistant

drivers, etc.) have been stored in a secure place and gate users/

maintenance personnel made aware of their locaon.

--

Loading...

Loading...