WEILER E1650 REMIXING TRANSFER VEHICLE

5-23

Maintenance

5

Maintenance Procedures

Take care when dispensing DEF. DEF that has been spilled will attack paint and metal. Clean spills

immediately. Wipe all surfaces clean and rinse with water.

Turn engine off before filling tank. Fill tank at the end of each day.

NOTICE: Stopping the engine immediately after the engine has been working under load can result

in overheating of DEF system components. Refer to

"Machine Shutdown Procedure", page 3-13 to

allow the engine to cool and to prevent excessive temperatures in the turbocharger housing and DEF

injector.

NOTICE: Do not turn Battery Ground Disconnect Switch off while Wait to Disconnect Lamp is

illuminated. Lamp remains on approximately 2 minutes after engine is shut down.

Refer to

"Fluid Capacities", page A-4 for DEF tank capacity.

Refer to the Engine Operation and Maintenance Manual for

DEF requirements.

NOTICE: Do not use agriculture grade urea solutions.

Do not use any fluids that do not meet “ISO 22241-1”

requirements in SCR emissions reduction systems. Use of

these fluids can result in numerous problems including

damage to SCR equipment and a reduction in NOx

conversion efficiency.

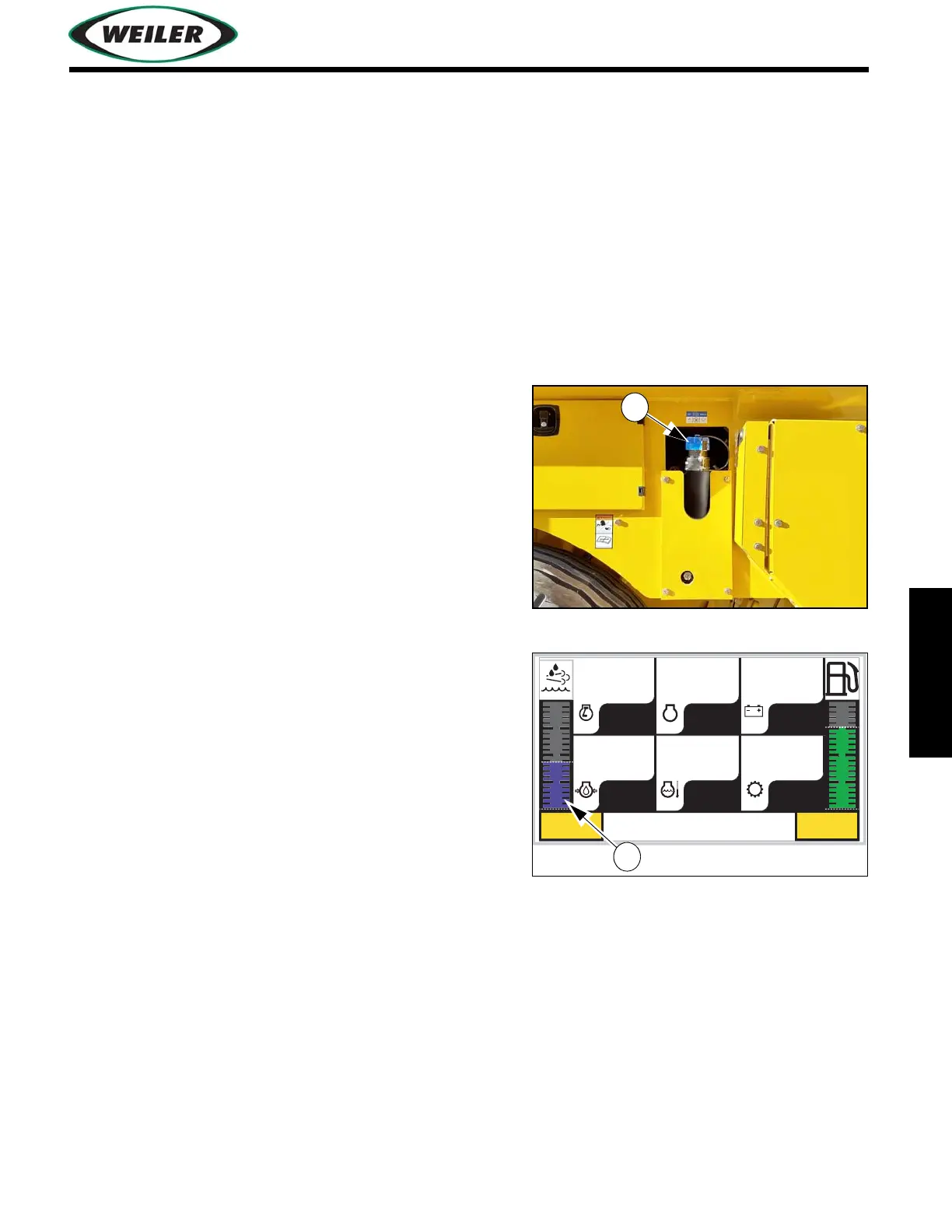

1. Remove blue DEF tank fill cap (1).

2. Fill DEF tank.

3. Install fill cap.

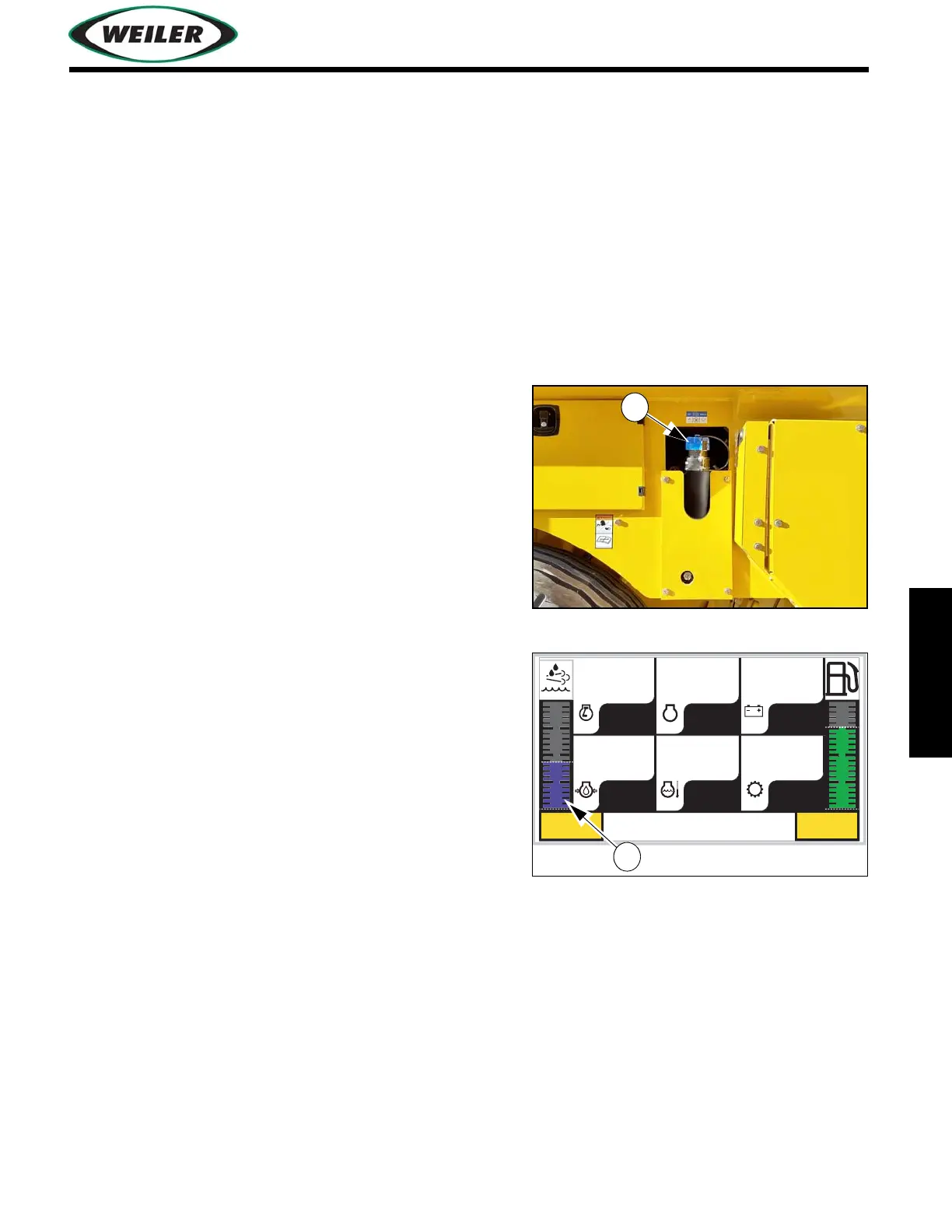

DEF level (2) is shown on main menu screen.

When DEF level is below 20%, low level notifications will

appear on Main Operating Screen. If DEF level is allowed

to reach a level of < 3.5% the engine will derate. If DEF

level = 0% the engine will be 100% derated and run at idle

speed.

%

DEF

1801 55 24.0

0125112

RPM Load VDC

PSI ° F FPM

Gauge

Data

Menu

15.0 Hours

05:35 PM 11/20/2016

Loading...

Loading...