WEILER E1650 REMIXING TRANSFER VEHICLE

5-47

Maintenance

5

Maintenance Procedures

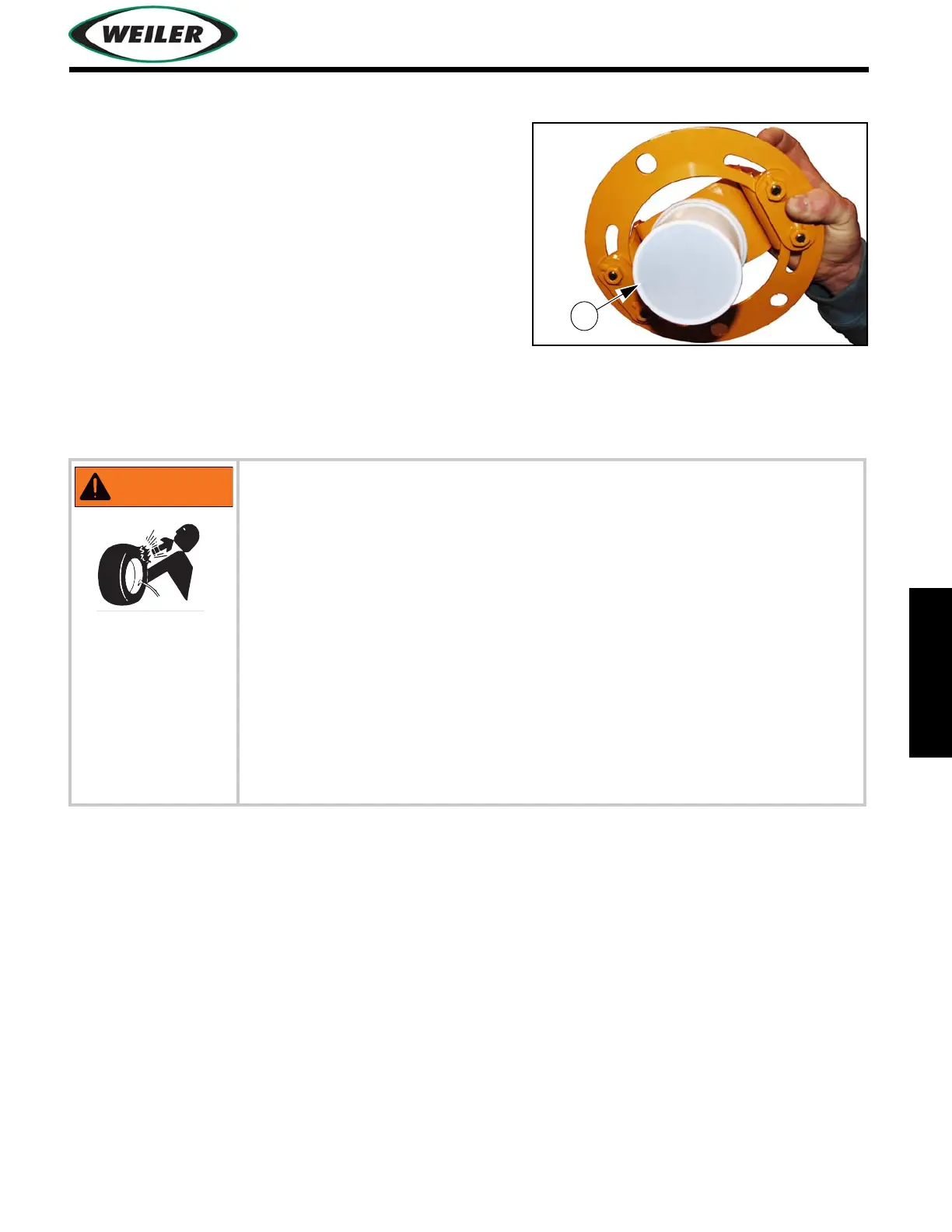

Storage Hopper Level Sensor - Check / Clean

1. Remove sensor assembly.

2. Check sensor lens (1) for debris and/or damage.

3. Clean lens with a non-abrasive, non-acidic cleaner.

4. If needed, replace sensor.

Tires - Check Pressure

Inflate tires to 94 psi (648 kPa). Check tires for excessive tread wear and sidewall damage.

Toggle Switches - Check

•Check toggle switches for freedom of movement.

•Check that non-detented toggle switches spring return to neutral or off when switch lever is

released.

WARNING

Explosion hazard.

• Use a clip-on air chuck with an in-line pressure gauge and a remote air

valve that allows you to stand behind the tread when inflating a tire.

• Never stand beside the tire when inflating.

• Maintain correct tire pressure. Do not inflate tire above recommended

pressure.

• Low tire pressure can result in internal tire damage. Inflate to

recommended pressure.

• Replace any tire with cuts or bubbles. Replace any damaged wheel.

• Do not weld or heat tire and wheel assembly. Heating will increase tire

pressure.

• Only trained and qualified personnel should mount, demount, or inflate

tires.

Loading...

Loading...