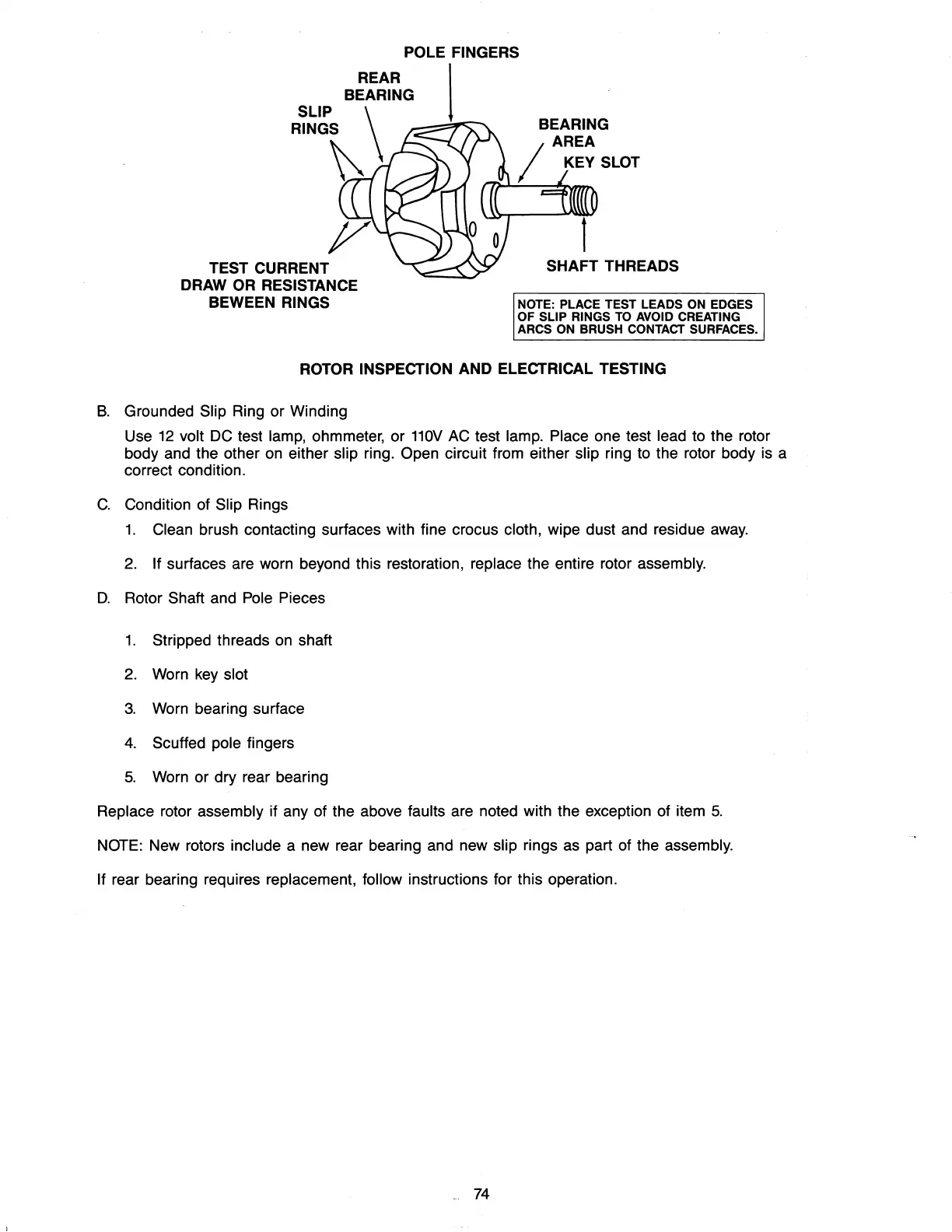

REAR

BEARING

SLIP \

RING~

TEST CURRENT

DRAW OR RESISTANCE

BEWEEN RINGS

BEARING

AREA

/ KEY SLOT

SHAFT

THREADS

NOTE: PLACE TEST LEADS ON EDGES

OF SLIP RINGS TO AVOID CREATING

ARCS ON BRUSH CONTACT SURFACES.

ROTOR INSPECTION AND ELECTRICAL TESTING

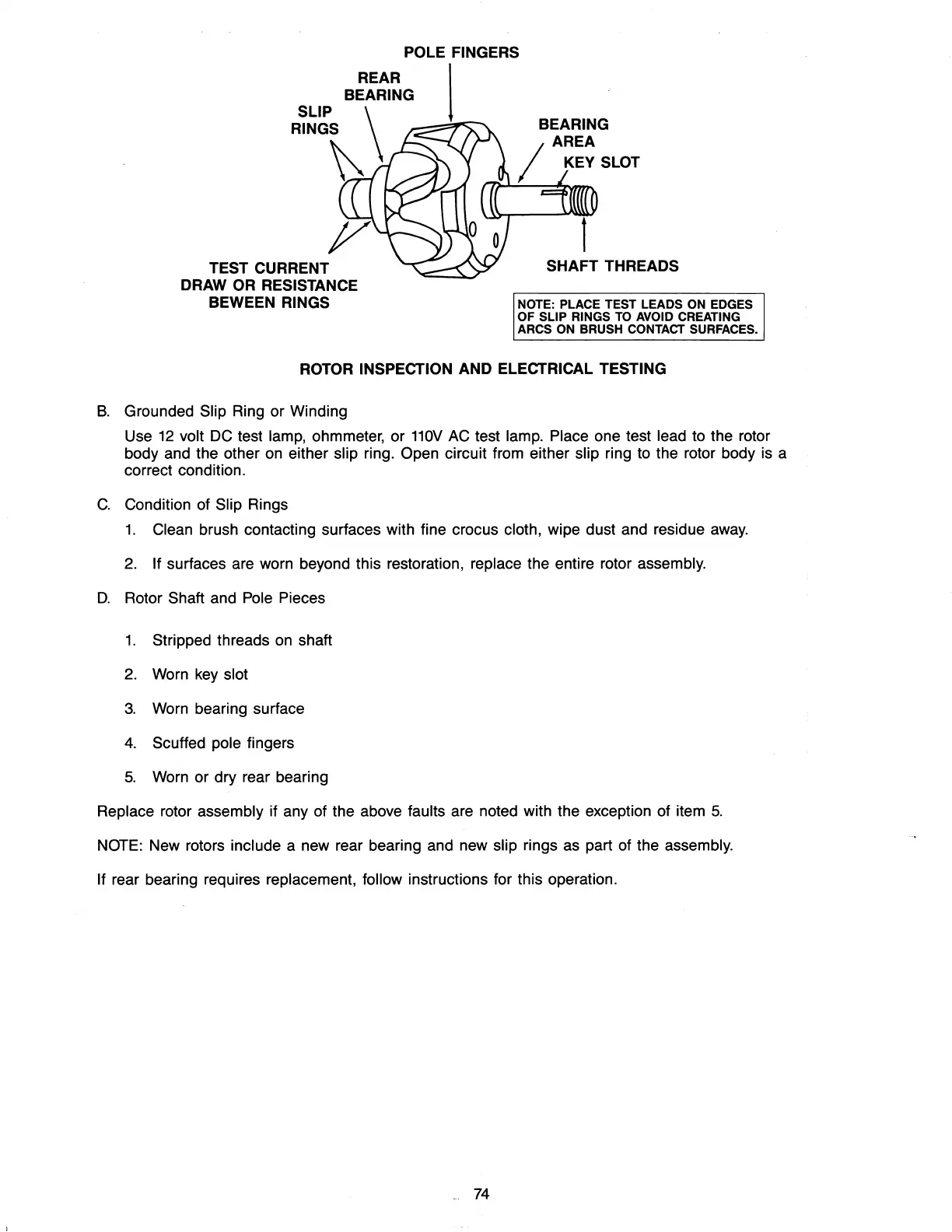

B.

Grounded Slip Ring or Winding

Use

12

volt

DC

test

lamp,

ohmmeter, or

110V

AC

test lamp. Place one test lead

to

the rotor

body

and

the other

on

either slip ring. Open circuit from either slip ring

to

the rotor body

is

a

correct condition.

C.

Condition of Slip Rings

1.

Clean brush contacting surfaces with fine crocus cloth, wipe dust and residue

away.

2.

If surfaces are worn beyond this restoration, replace the entire rotor assembly.

D.

Rotor Shaft and

Pole

Pieces

1.

Stripped threads

on

shaft

2.

Worn

key

slot

3.

Worn

bearing surface

4. Scuffed pole fingers

5.

Worn

or dry rear bearing

Replace rotor assembly if any of the above faults are noted with the exception of item

5.

NOTE:

New

rotors include a new rear bearing and new slip rings as part of the assembly.

If

rear bearing requires replacement, follow instructions for this operation.

_

74

Loading...

Loading...