40 Instructions for use

EN

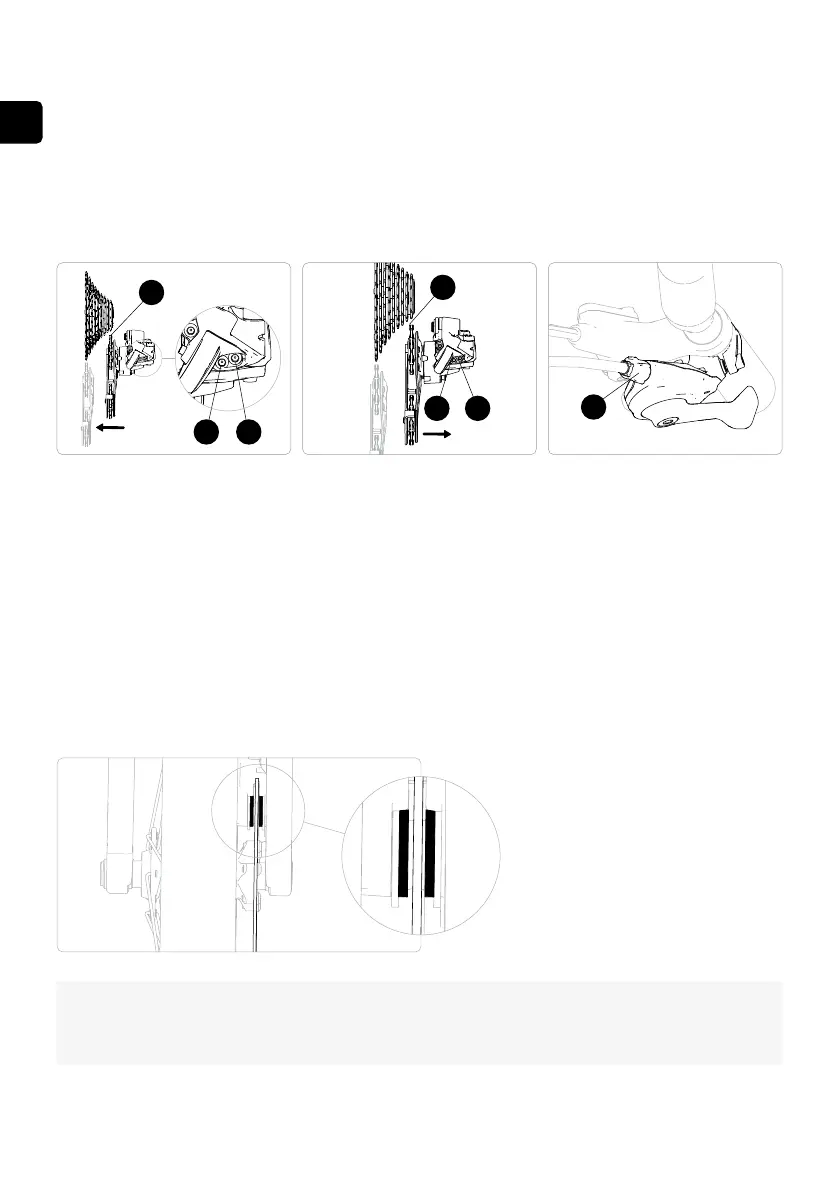

© Turning the adjustment screw (H) clockwise OR the adjustment screw (L) anti-clockwise will move the jockey

wheel (1) towards the wheel.

© Turning the adjustment screw (H) anti-clockwise OR the adjustment screw (L) clockwise will move the jockey

wheel (1) away from the wheel.

Gear adjustment: Shift through all gears starting with the smallest sprocket. If the chain does not shift to the next

largest sprocket after activating the trigger shifter, tighten the gear cable by turning the barrel adjuster (2) on the

trigger shifter anti-clockwise. If the chain skips several sprockets during a single shift, reduce the gear cable tension

by turning the barrel adjuster (2) on the trigger shifter clockwise.

7�5 The brakes

Brake pads must not come into contact with oil or grease. Be careful not to touch hot surfaces (e.g. hot disc brake

rotor after heavy use). Your disc brake rotors and brake pads are all parts susceptible to wear and tear, so they need

to be inspected at regular intervals (see section 7.8 Maintenance schedule). The brakes must be checked or serviced

by a specialist in any case if:

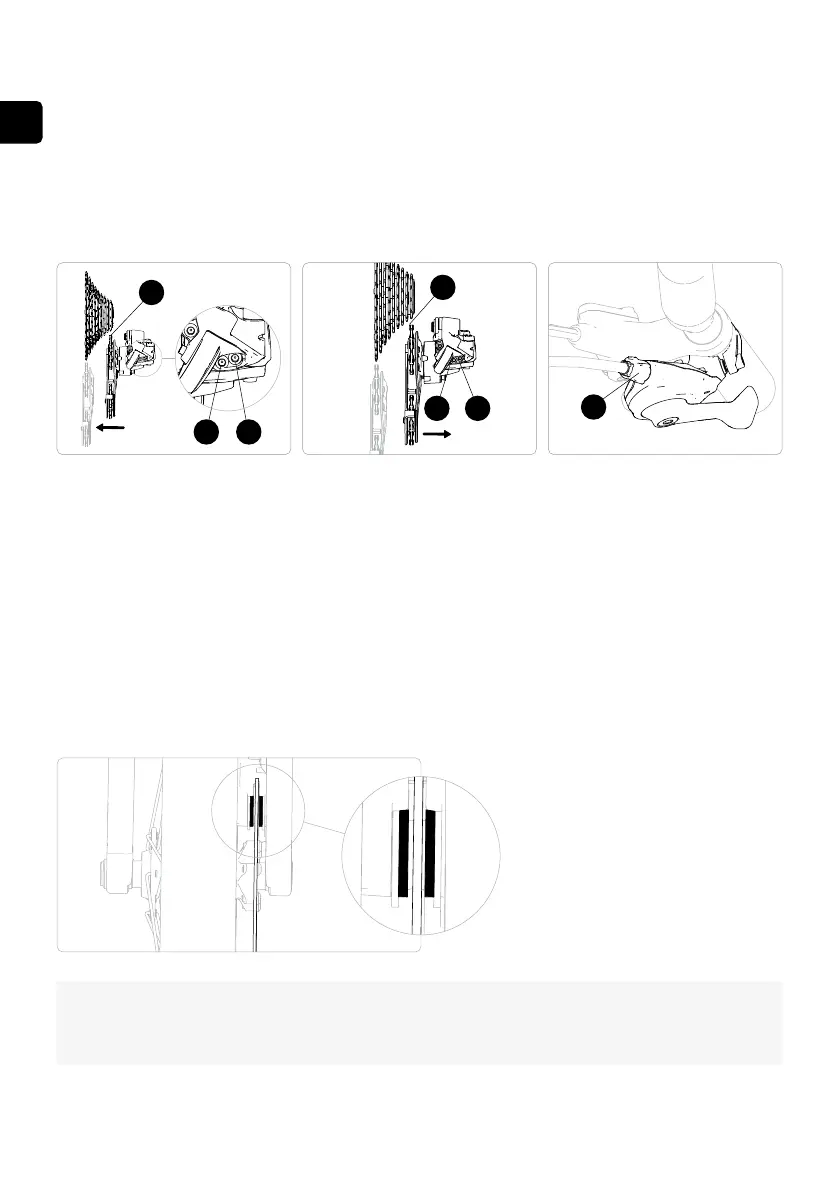

© the brake pads are less than 0.5 mm in thickness;

© the brake lever touches the handlebars when braking;

© the brakes screech or vibrate;

© braking power decreases;

© the brakes “oat”, i.e. have a variable bite point.

Checking the thickness of the brake pads

TOP TIP

We recommend fully servicing your brakes every 12–24 months, depending on how often the

bike is used. However, remember that brake uid will still age even if the bike is rarely used.

Loading...

Loading...