8.6 Operating Using Position Control

8-53

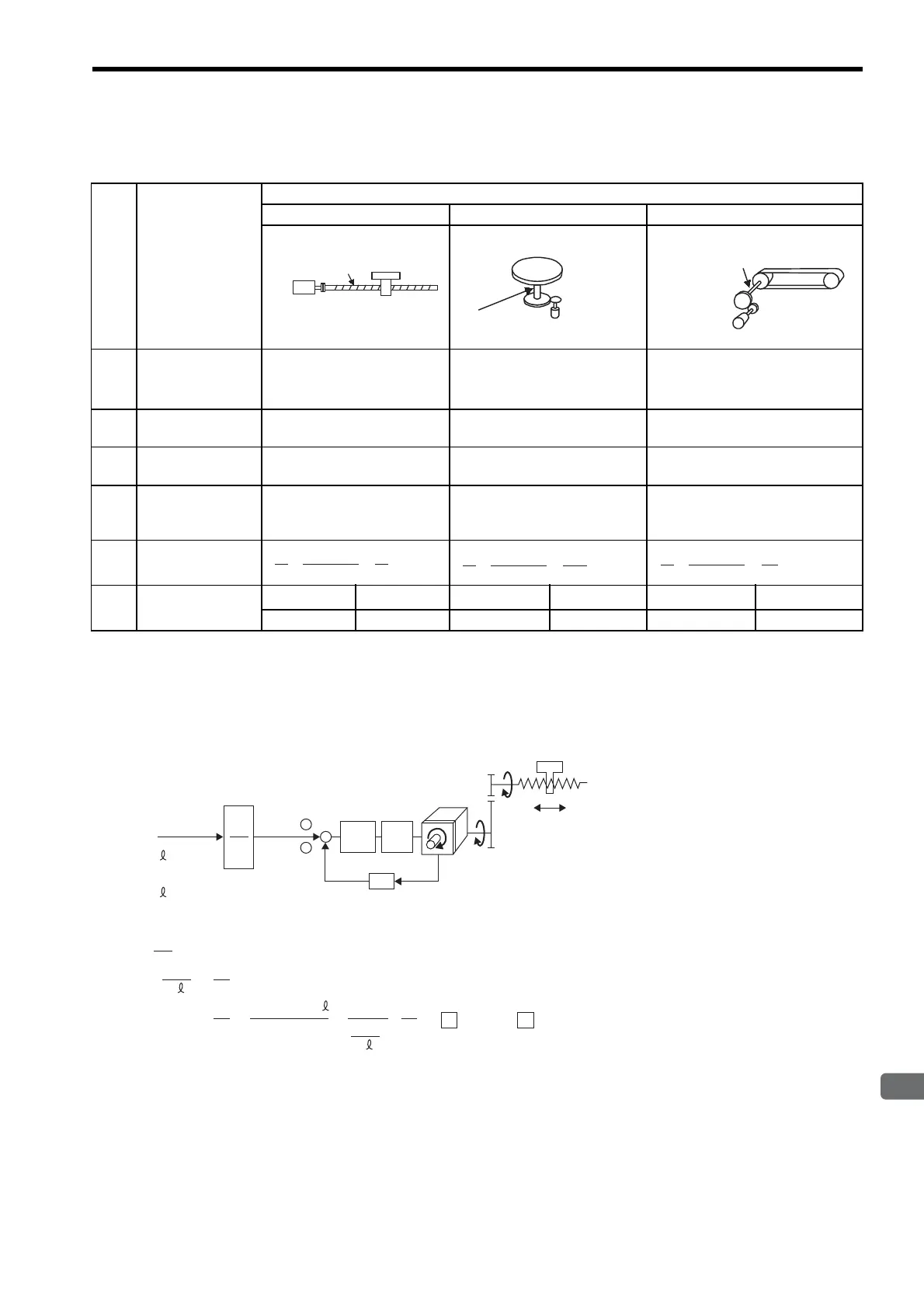

(5) Electronic Gear Ratio Setting Examples

The following examples show electronic gear ratio settings for different load configurations.

Reduce the fraction (both numerator and denominator) since the calculated result will not be within the setting

range. For example, reduce the numerator and denominator by four to obtain Pn201=32768, Pn203=3925 and

complete the settings.

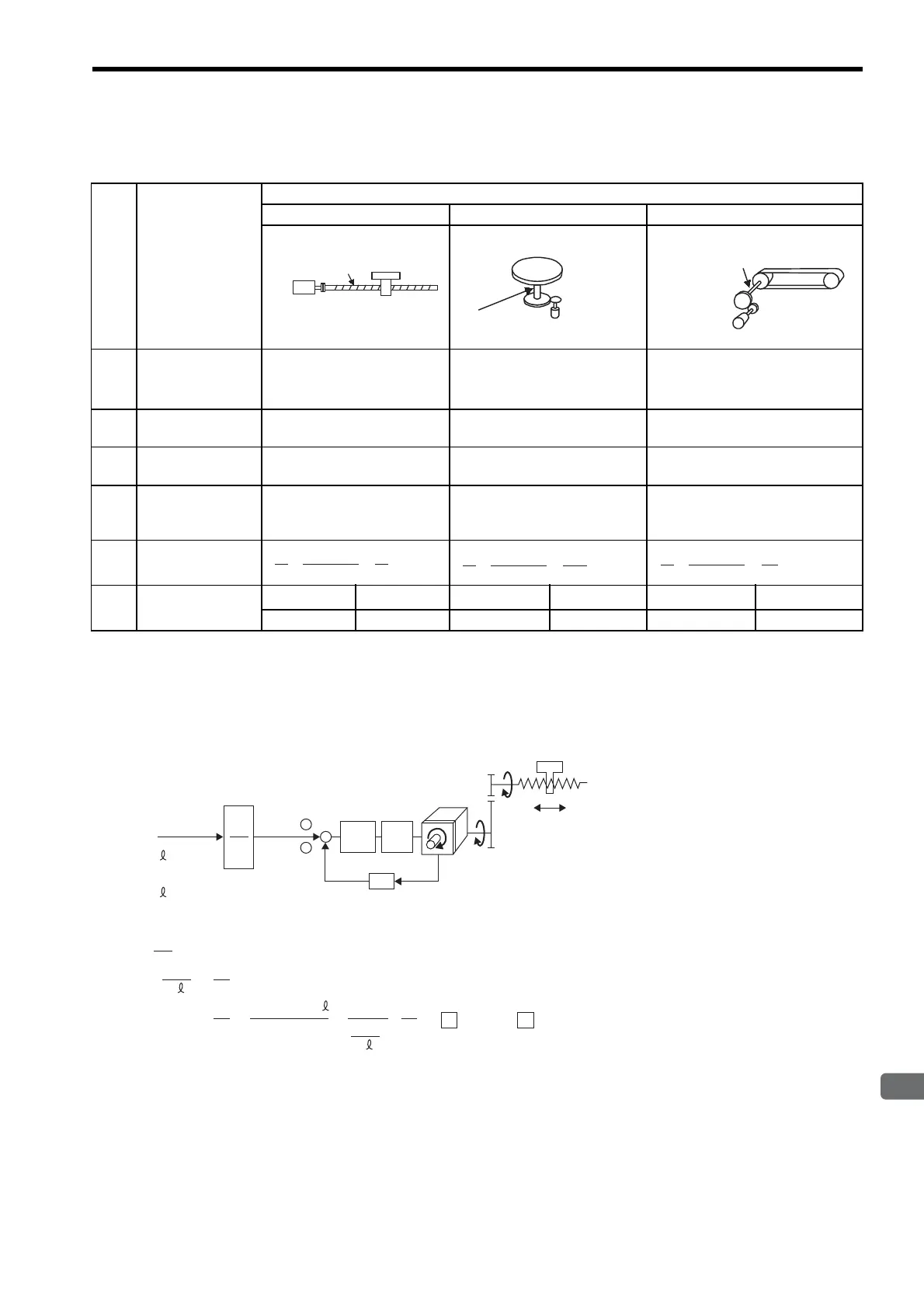

(6) Electronic Gear Ratio Equation

Step Operation

Load Configuration

Ball Screw Disc Table Belt and Pulley

1

Check machine

specifications.

x

Ball screw pitch: 6 mm

x

Deceleration ratio: 1/1

Rotation angle per revolution:

360°

Deceleration ratio: 3/1

Pulley diameter: 100 mm

(pulley circumference: 314 mm)

x

Deceleration ratio: 2/1

2

Check the number

of encoder pulses.

13-bit: 2048 P/Rev 13-bit: 2048 P/Rev 16-bit: 16384 P/Rev

3

Determine the ref-

erence unit used.

1 Reference unit: 0.001 mm

(1 μm)

1 Reference unit: 0.1

°

1 Reference unit: 0.02 mm

4

Calculate the travel

distance per load

shaft revolution.

6 mm/0.001 mm=6000

360

°/0.1°=3600

314 mm/0.02 mm=15700

5

Calculate the elec-

tronic gear ratio.

6

Set parameters.

Pn202 8192 Pn202 24576 Pn202

131072

∗

Pn203 6000 Pn203 3600 Pn203 15700

Ball screw

pitch: 6 mm

13-bit encoder

Load shaft

Reference unit: 0.001 mm

13-bit encoder

Load shaft

Reference unit: 0.1°

Deceleration

ratio:

3 : 1

Load shaft

Deceleration

ratio

2 : 1

Reference Unit: 0.02 mm

Pully diameter:

100 mm

16-bit encoder

A

B

n

m

+

-

×4

Pitch = P (mm/rev)

m

n

Servomotor

P

G

(P/rev)

P

G

(P/Rev): Encoder pulses

Position

loop

Speed

loop

Reference pulse

Δ (mm/P)

n × P

n × P

B

Δ A

G

Δ (mm/P): Reference unit

P

Δ

Δ

×

×

()

m

n

= 4 × P × m

B

A

()

==

G G

4 × P × m × 4 × P

Set A and B with the following parameters.

A

㧦Pn203

B

㧦Pn202

P (mm/Rev): Ball screw pitch

: Deceleration ratio

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...