Basic Programming 5 - 20

To configure Torque Detection requires the following decisions:

a. Do you wish to check for an overtorque condition or an undertorque condition?

b. Do you wish to check for the torque condition whenever the Drive is running or only at speed agree? Nuisance detection

during acceleration, when high torques are normally required, can be avoided by using Torque Detection only at Speed

Agree.

c. Do you want the Drive to fault if the torque condition is detected, or only alarm and continue operation?

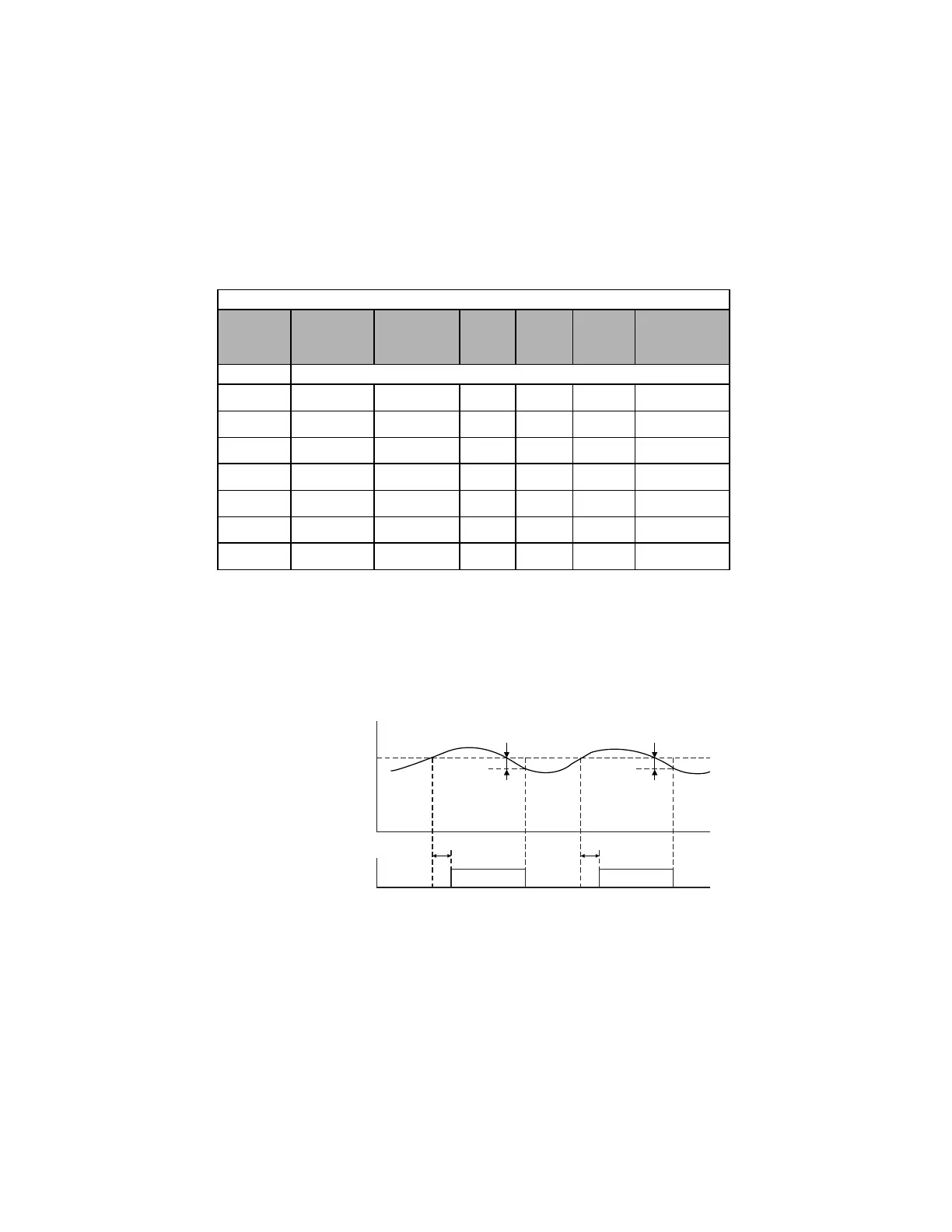

The following table can help choose the proper setting for Torque Detection Selection:

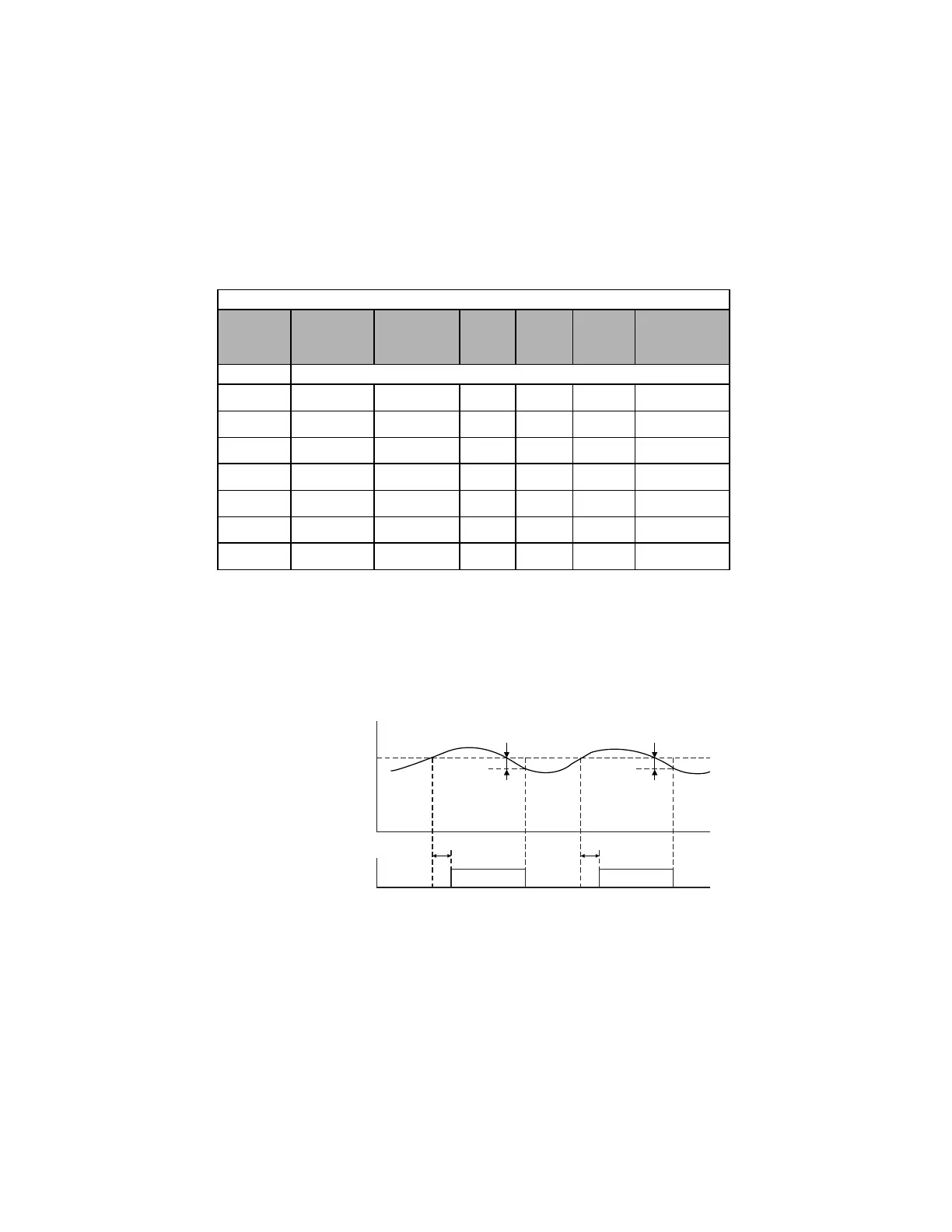

After selecting the proper detection scheme, the Torque Detection Level (L6-02) must be specified. If the current level read

by the output DCCTs rises above (overtorque), or drops below (undertorque), and remains there for at least the Torque Detec-

tion Time (L6-03). The Torque Detection Function will change the state of any digital output configured for Torque Detection

(H2-01/H2-02=B or 17).

Fig 5.18 Over Torque Detection Timing Chart

Table 5.3 L6-01 Setting Choices

L6-01

Setting

Overtorque Undertorque Fault Alarm

Always

Detected

Only

Detected at

Spd Agree

0 Torque Detection Disabled

1

***

2

***

3

** *

4

***

5

** *

6

***

7

** *

*

*

L6-02 or L6-05

L6-03 or

L6-06

L6-03 or

L6-06

Overtorque detection 1 NO

or overtorque detection 2 NO

ON ON

* Overtorque detection disabled band is approximately 10% of the Inverter rated output

current (or motor rated torque).

Motor current (output torque)

Loading...

Loading...