Electrical Installation 2 - 12

Control Wiring

Control Circuit Wire Sizes

For remote operation, keep the length of the control wiring to 50m or less. Separate the control wiring from high-power lines

(input power, motor leads or relay sequence circuits) to reduce noise induction from peripheral devices.

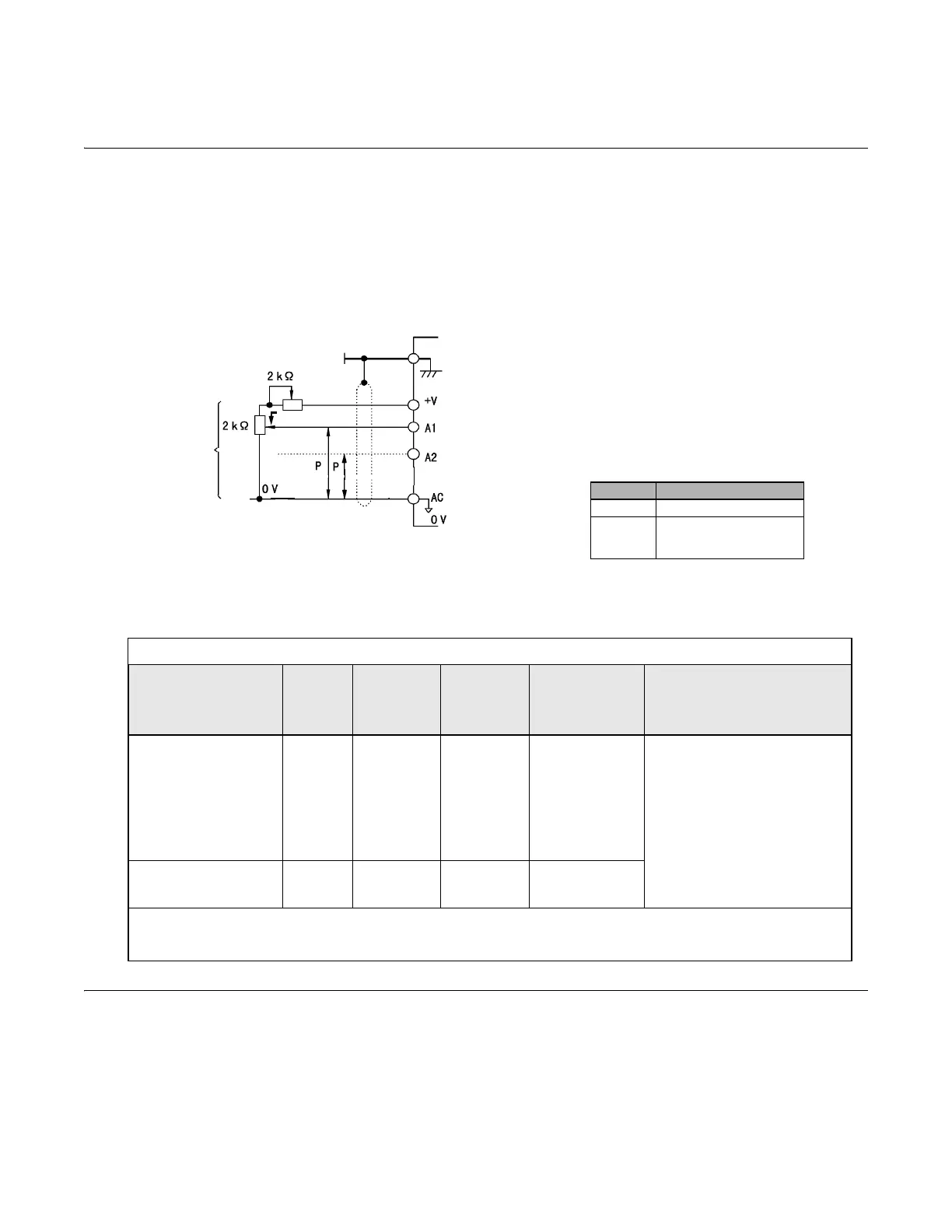

When setting speed commands from an external speed potentiometer (and not from the Digital Operator), use shielded

twisted-pair wires and ground the shield to terminal E(G), as shown in Fig 2.5. Terminal numbers and wire sizes are shown in

Table 2.7.

Fig 2.5 Analog Input Terminal Configuration

Wiring Checks

After all wiring is completed, perform the following checks:

1. Is all wiring correct?

2. Have all wire clippings, screws or other foreign material been removed from the Drive enclosure?

3. Are all terminal screws tight?

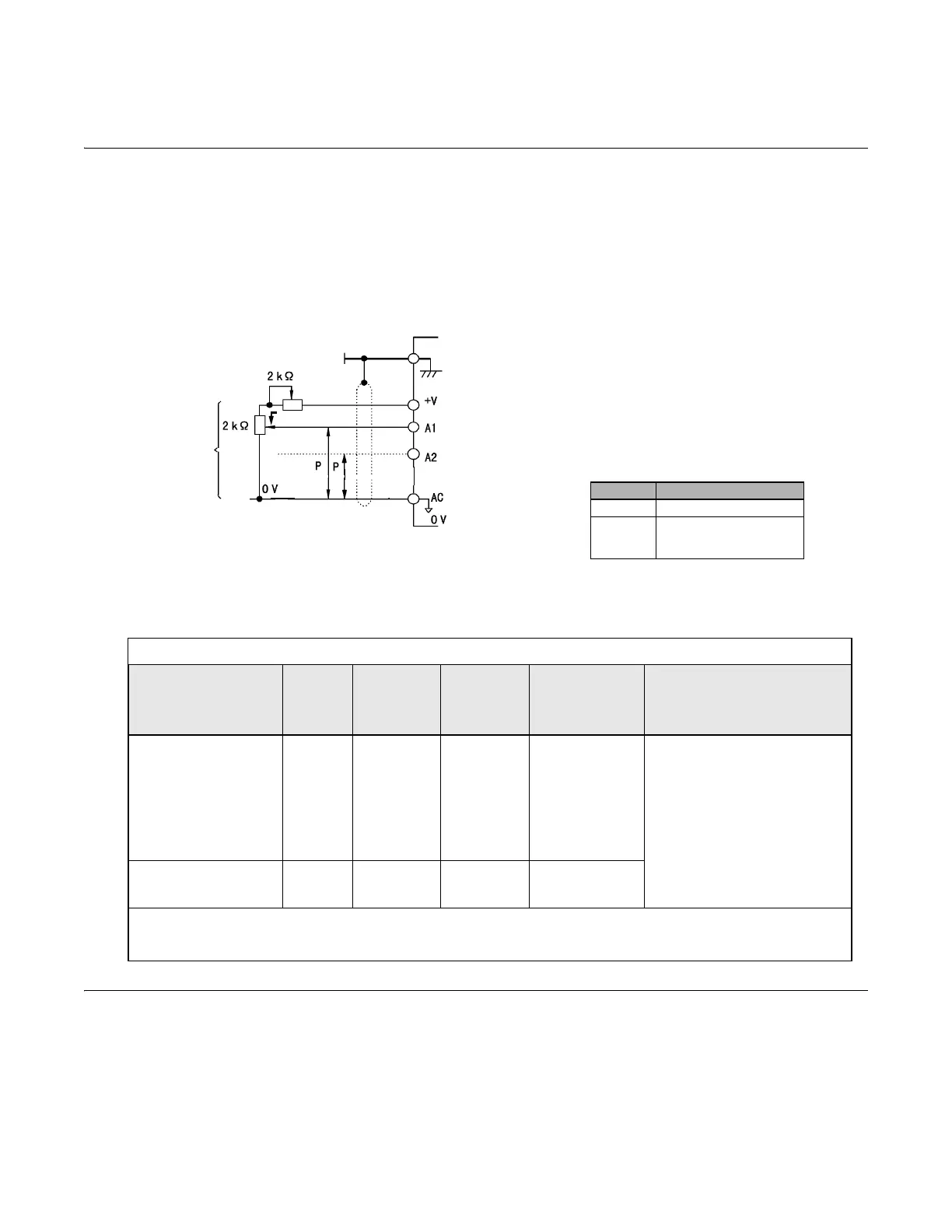

Table 2.7 Terminal Numbers and Wire Sizes (Same for all Drives)

Terminals

Te r mi nal

Screws

Tightening

Torque

lb-in

(N•m)

Possible

Wire Sizes

AWG (mm

2

)

Recommended

Wire Size AWG

(mm

2

)

Wire Type

S1, S2, S3, S4, S5, S6, S7

SN, SC, SP, +V, A1, A2,

AC, MI, M2, M3, M4,

MA, MB, MC, FM, AC,

AM, R+, R-, S+, S-, IG

Phoenix

type

*3

4.2 to 5.3

(0.5 to 0.6)

Stranded

wire:

26 to 16

(0.14 to 1.5)

18

(0.75)

• Shielded, twisted-pair wire

*1

• Shielded, polyethylene-covered,

vinyl sheath cable

E(G) M3.5

7.0 to 8.8

(0.8 to 1.0)

20 to 14

(0.5 to 2

*2

)

12

(1.25)

*1.Use shielded twisted-pair cables to input an external speed command.

*2.Yaskawa recommends using straight solderless terminals on digital inputs to simplify wiring and improve reliability.

*3. Yaskawa recommends using a thin-slot screwdriver with a 3.5 mm blade width.

External

frequency

reference

0 to +10 V

4 to 20 mA

Shield terminal

Speed setting power supply, +15 Vdc, 20 mA

Speed command, 0 to 10 Vdc (20 kΩ)

Speed command, 4 to 20 mA (250 Ω)/0 to +10 Vdc (20 kΩ)

Signal Terminal Connections

0-10Vdc A1 to AC

4-20mA

or

0-10Vdc

A2 to AC

E (G)

Trim Potentiometer

(

)

Loading...

Loading...