6-52

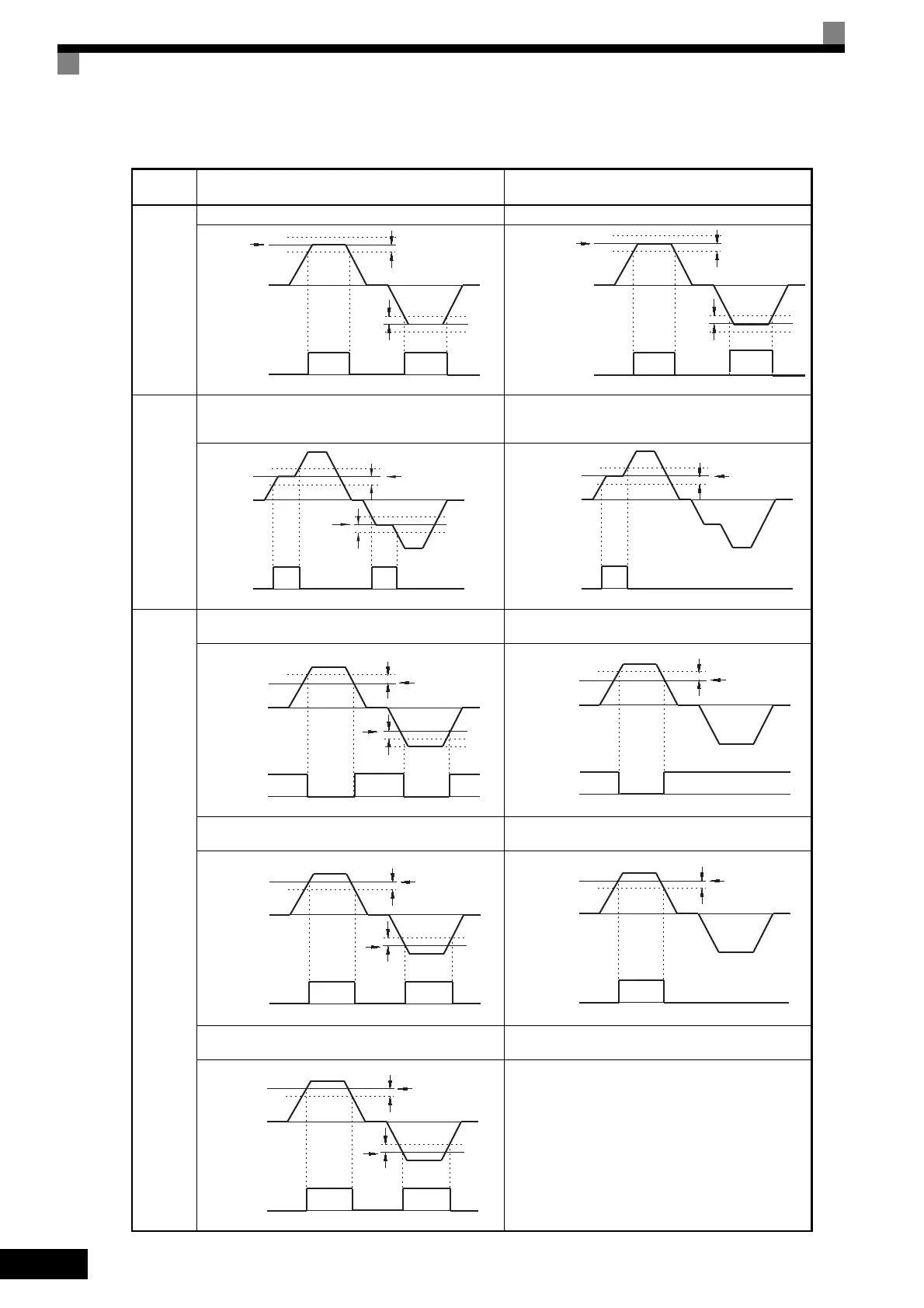

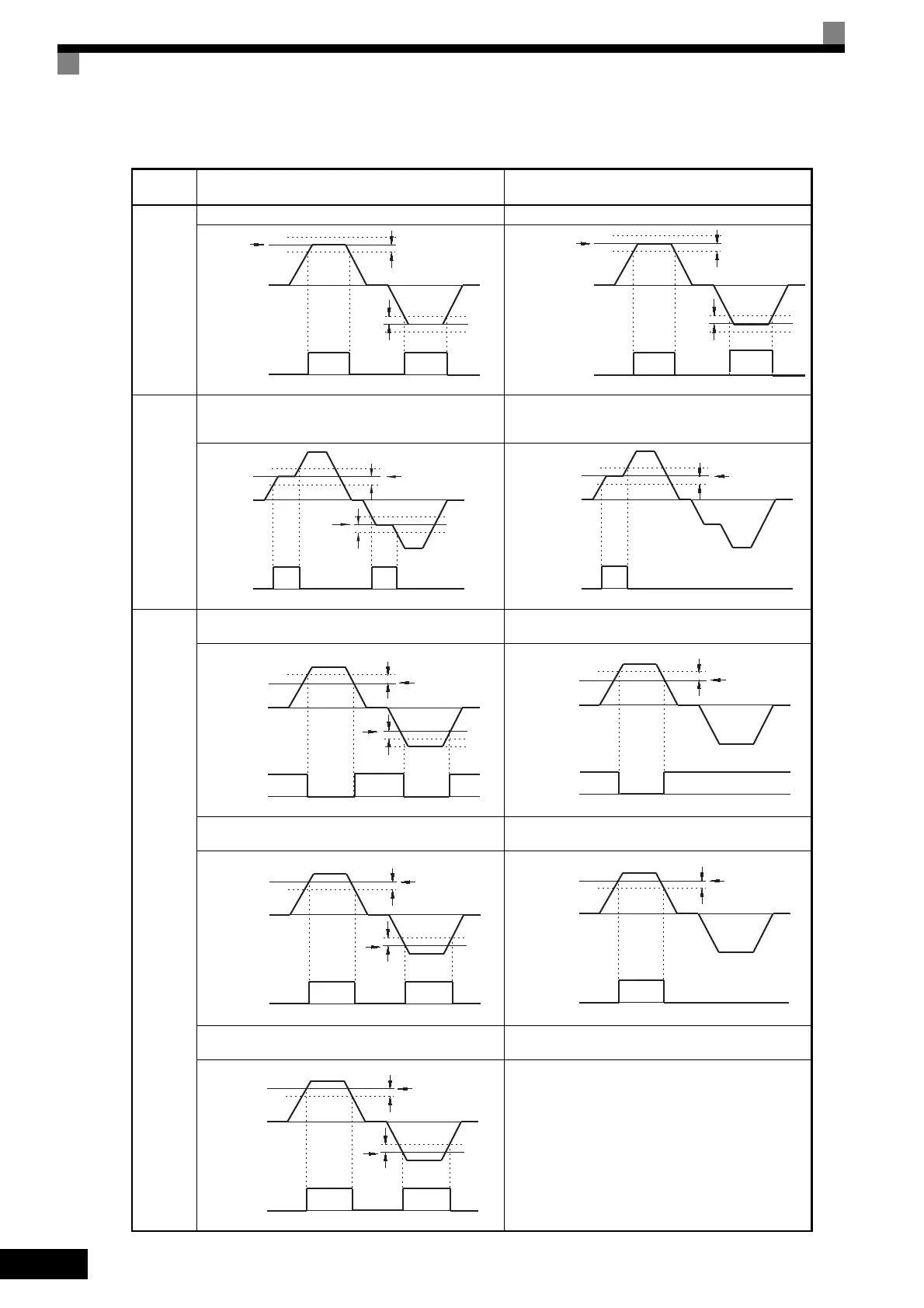

Timing Chart for Frequency Detection Operation

Related

constant

L4-01: Speed Agree Level

L4-02: Speed Agree Width

L4-03: Speed Agree Level +/−

L4-04: Speed Agree Width +/−

Fref/Fout

Agree

Fref/Fout Agree 1 Fref/Fout Agree 2

Fref/Set

Agree

Fref/Set Agree 1

(ON at the following conditions during frequency

agree)

Fref/Set Agree 2 +/−

(ON at the following conditions during frequency

agree)

Fre-

quency

Detection

Frequency (FOUT) Detection 1

(L4-01 > | Output frequency |)

Frequency (FOUT) Detection 3

(L4-03 > Output frequency)

Frequency (FOUT) Detection 2

(L4-01 < | Output frequency |)

Frequency (FOUT) Detection 4

(L4-01 < Output frequency)

Frequency (FOUT) Detection 5

(L4-01 < | Output frequency |)

L4-02

OFF ON

Frequency

reference

L4-02

Output frequency

or motor speed

Fref/Fout Agree 1

(Multi-function output setting = 2)

OFF ON

Frequency

reference

Output frequency

or motor speed

Fref/Fout Agree 2

L4-04

(Multi-function output setting = 13)

OFF ON

tput frequency

motor speed

f/Set Agree 1

L4-02

L4-01

L4-01

L4-02

(Multi-function output setting = 3)

OFF ON

Output frequency

or motor speed

Fref/Set Agree 2

L4-04

L4-03

(Multi-function output setting = 14)

Freq. Detection 1

OFFON

Output frequency

or motor speed

L4-02

L4-02

L4-01

L4-01

(Multi-function output setting = 4)

Freq. Detection 3

OFFON

Output frequency

or motor speed

L4-04

L4-03

(Multi-function output setting = 15)

Freq. Detection 2

OFF ON

Output frequency

or motor speed

L4-02

L4-02

L4-01

L4-01

(Multi-function output setting = 5)

Freq. Detection 4

OFF ON

Output frequency

or motor speed

L4-04

L4-03

(Multi-function output setting = 16)

Freq. Detection 5

OFF ON

Output frequency

or motor speed

L4-02

L4-02

L4-01

L4-01

(Multi-function output setting = 36) OFF during baseblock

Loading...

Loading...