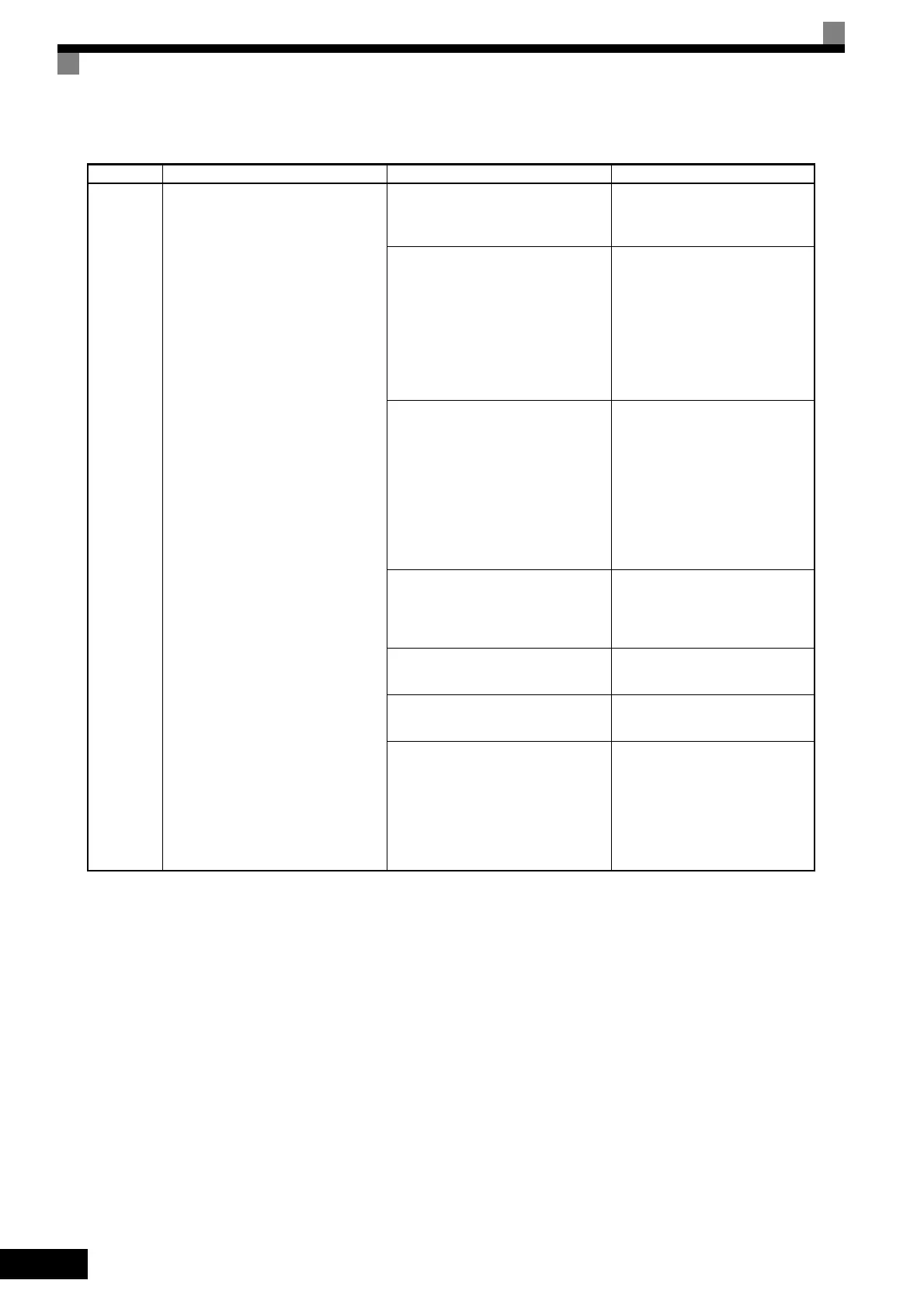

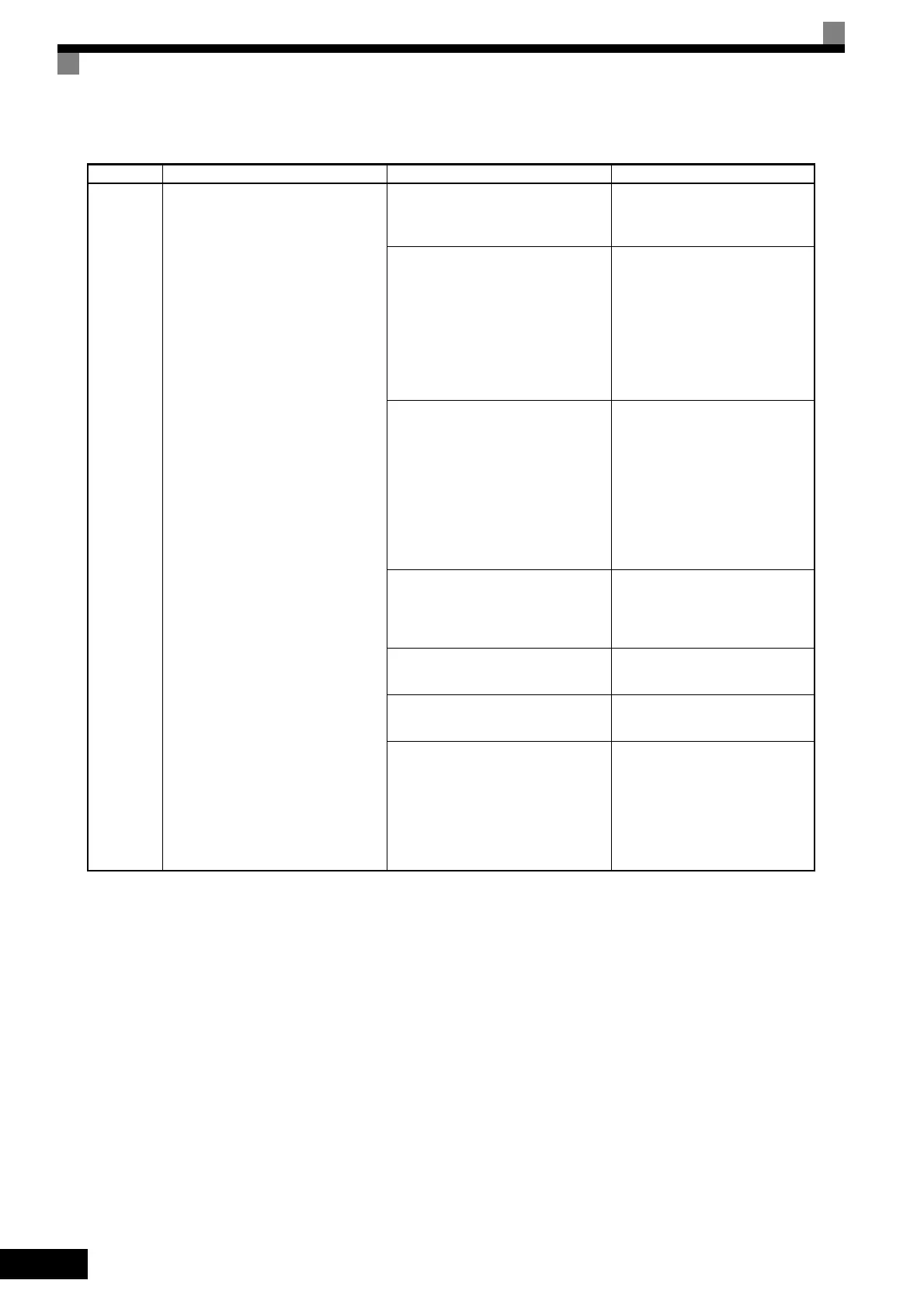

7-6

OL1

电机过载

Motor Overload

The motor overload protection func-

tion has operated based on the internal

electronic thermal value.

The load is too heavy. The accelera-

tion time, deceleration time, and cycle

time are too short.

Check the size of the load and the

length of the acceleration, deceler-

ation, and cycle times.

The constant setting for speed search

is incorrect.

(Motor overload occurred due to

motor hunting and vibration.)

• Use the speed search function.

• Adjust the settings of the Speed

search operating current (b3-02)

and Speed search deceleration

time (b3-03).

• Use the estimated speed search

function. (Perform stationary

autotuning for line-to-line resis-

tance only.)

• Motor overload occurred when run-

ning at low speed. (If a general-pur-

pose motor is used, motor overload

can occur when running at low

speed even if running within the

rated current.)

• Motor protection selection (L1-01)

is set to general-purpose motor pro-

tection (1) when an Inverter duty

motor is used.

• Check the size of the load.

• Check the setting of L1-01.

• Increase the frame size of the

Inverter.

The directions of the motor and PG

are different. (Only in flux vector con-

trol)

• Correct the PG wiring.

• Correct the motor wiring.

• Change the setting of PG rota-

tion (F1-05).

The V/f characteristics voltage is too

high.

Check the V/f characteristics.

The Motor Rated Current (E2-01) is

incorrect.

Check the Motor Rated Current

(E2-01).

• A short-circuit between +V, −V, and

AC terminals occurred.

• Overload in the control circuit ter-

minal.

• Make sure that incorrect wiring

has not been done.

• Check the resistance and wir-

ing for the frequency setting

potentiometer, etc. (Check that

the current for terminals +V and

–V is 20 mA or less.)

Table 7.1 Fault Displays and Processing (Continued)

Display Meaning Probable Causes Corrective Actions

Loading...

Loading...