1-26

IM WT3001E-51EN

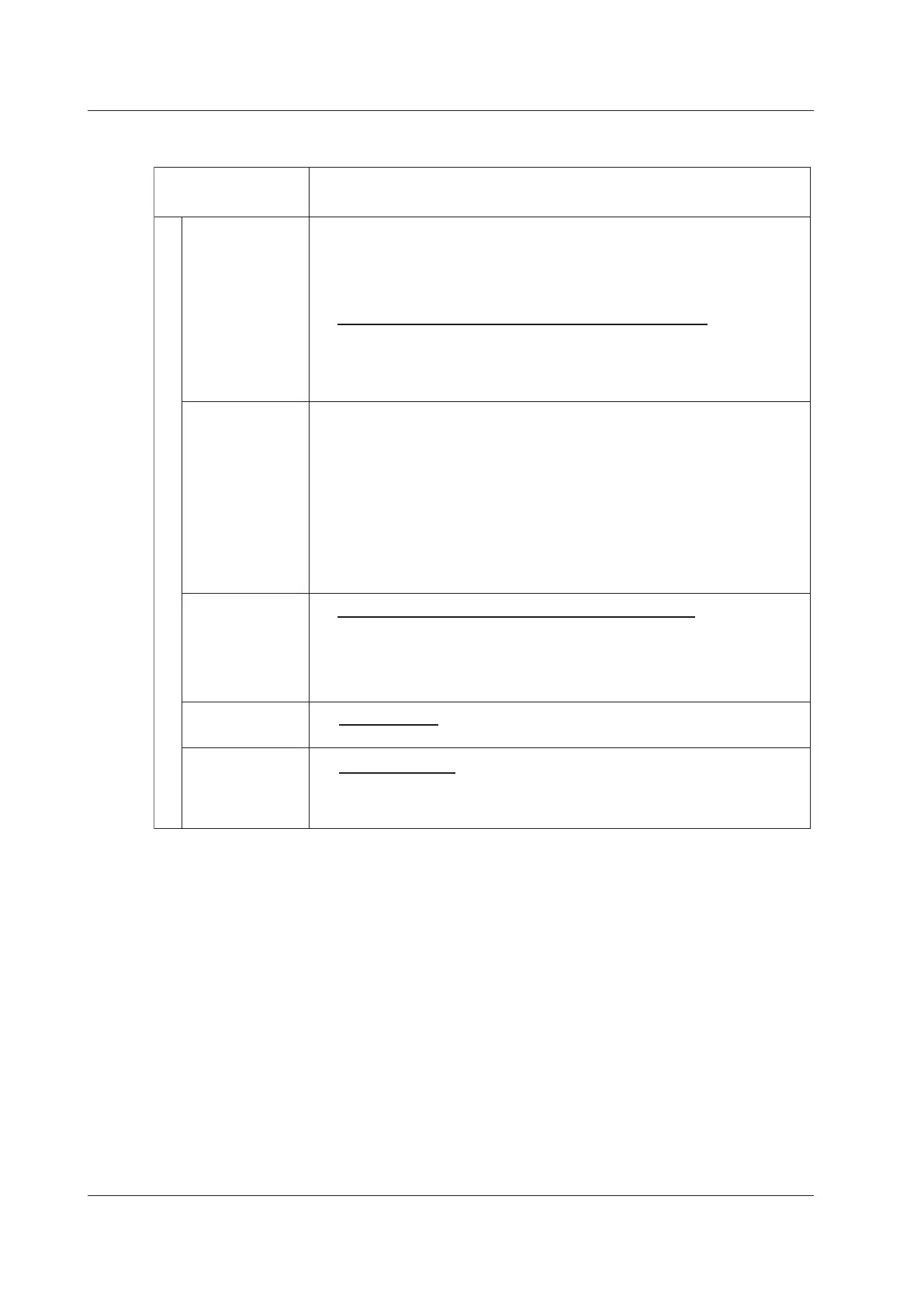

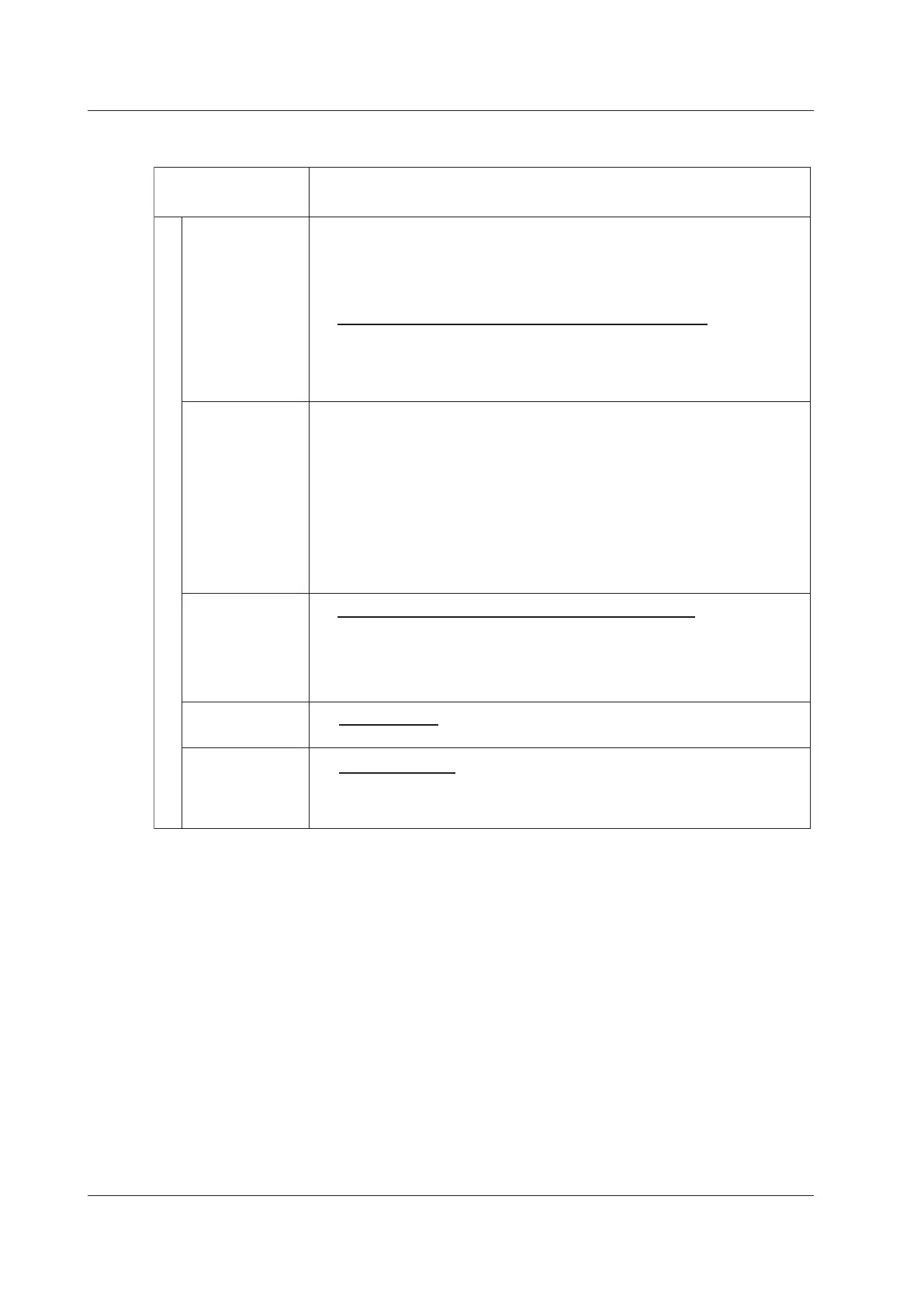

Symbols and Determination of Motor Evaluation Measurement Functions

Measurement Functions

during Normal

Measurement

Method of Determination, Equation

Motor evaluation

Rotating

speed

Synchronous

speed

Slip

[%]

Motor

output

Pm

Torque

When the type of input signal from the revolution sensor is DC voltage (analog signal)

When the type of input signal from the revolution sensor is pulse count

Input voltage from the revolution sensor

•

Scaling factor

Number of input pulses from the revolution sensor per minute

Number of pulses per rotation

• Scaling factor

• Scaling factor

Motor’s number of poles

Scaling factor: Number of rotations per volt of input voltage

Scaling factor

• input voltage from the torque meter

•

100

Scaling factor: torque per volt of input voltage

Scaling factor: When the signal of the gear ratio or revolution sensor is a

converted signal, you can specify the gear ratio for the scaling factor to

determine the rotating speed before the gear change.

• The unit of synchronized speed is fixed to “min

–1

(or rpm).”

• Normally, the frequency measurement source is set to the voltage or current

that is supplied to the motor. The synchronized speed may not be

determined correctly if a different signal is specified.

When the unit of speed is “min

–1

(or rpm),” the unit of torque is “N·m,” and the

scaling factor is 1, the unit of motor output Pm is “W.”

SyncSp – Speed

SyncSp

• •

2 Torque Speed

60

When type of input signal from the torque meter is DC voltage (analog signal)

When the type of input signal from the torque meter is pulse count

Torque pulse coefficient and torque pulse offset: Calculated in this instrument

from the torque values [N·m] at two points corresponding to the upper and

lower limits of frequency.

Scaling factor: Normally, use the value of 1. When using a unit other than N·m,

set the conversion ratio of the unit.

(Torque pulse coefficient • pulse frequency + torque pulse offset) • scaling factor

120 Frequency of the frequency measurement source (Hz)

•

Set the efficiency equation or user-defined function to determine the motor efficiency and total efficiency.

1.10 Specifications of the Motor Evaluation Function

Loading...

Loading...