Ventilator & Calibration Troubleshooting

906-0731-04-01 Rev. C ZOLL Ventilator Service Manual 6–19

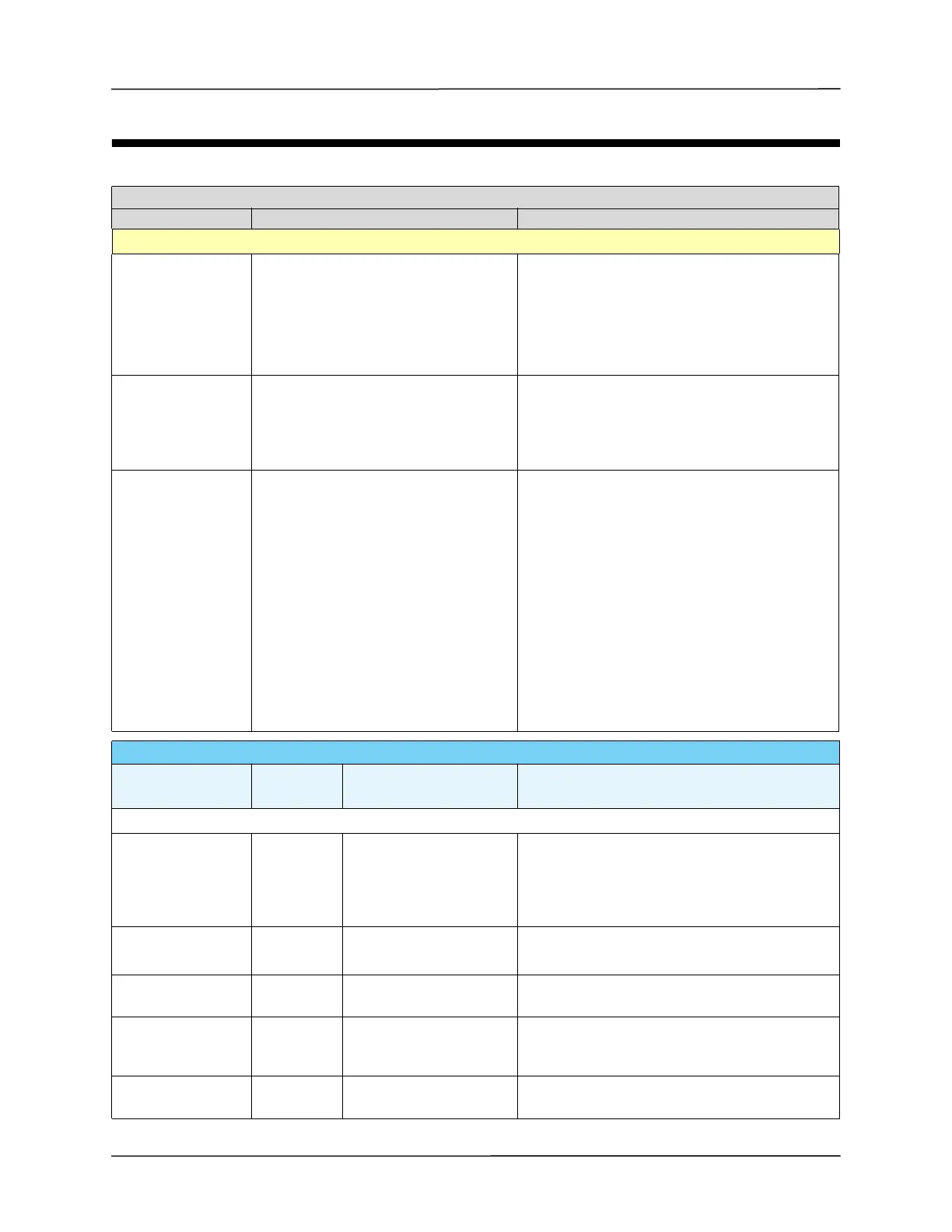

Troubleshooting — Compressor System Calibration

Remote Calibration System

Discrete Tests Test Purpose/ Definition Troubleshooting

Note: Within the status area or log file, the middle number indicates measured gain. Ex: 22588 < 29266 < 41168

Intake Pressure

Calibration

IP_Offset

(range: 22588 - 41168)

IP_Gain

(range: 28045 - 54968)

• Check set up

• Gain Too Low – check assembly for restrictions or

damaged filters. Check torque used in assembly of

intake.

• Gain Too High – check assembly to ensure all intake

components (filters, O-rings, etc.) have been

installed.

• Check for damaged fresh gas intake filters.

Compressor Flow

Calibration

CF_Offset

(range: 26823 - 35474)

CF_Gain

(range: 23322 - 33584)

• Check set up

• Gain Too Low – clean flow screens and re-install.

• Gain Too High – check test setup and assembly for

leaks, then recalibrate.

Calibration Check

Compressor System

Compares selected flow values to published

specifications (incoming), or tighter

(outgoing) limits to allow for drift.

Also Checks Intake Pressure, Compressor

RPM, Airway Pressure to ensure correct

compressor performance.

Airflow tolerance ± (0.1 LPM + 5% of setting)

Intake tolerance ± 15% of ADC target values

(Note: ADC target values are altitude

compensated) RPM tolerance ± 15% of RPM

target.

• Review active service codes refer to the Service

code troubleshooting sheet

• Intake assembly may not be tight replace disk filter)

• Tighten intake assembly

• RPM (caused by a leak during calibration) fails check

Anti-Asphyxia valve, then recalibrate

• low flow may be leak

• High flow, recalibrate

• filters may be dirty

• Replace filters

• anti-asphyxia valve may be faulty

• Replace ant-asphyxia valve

• Check test setup for leaks

• Compressor flow failures require re-calibration.

Ensure setup is correct during calibration.

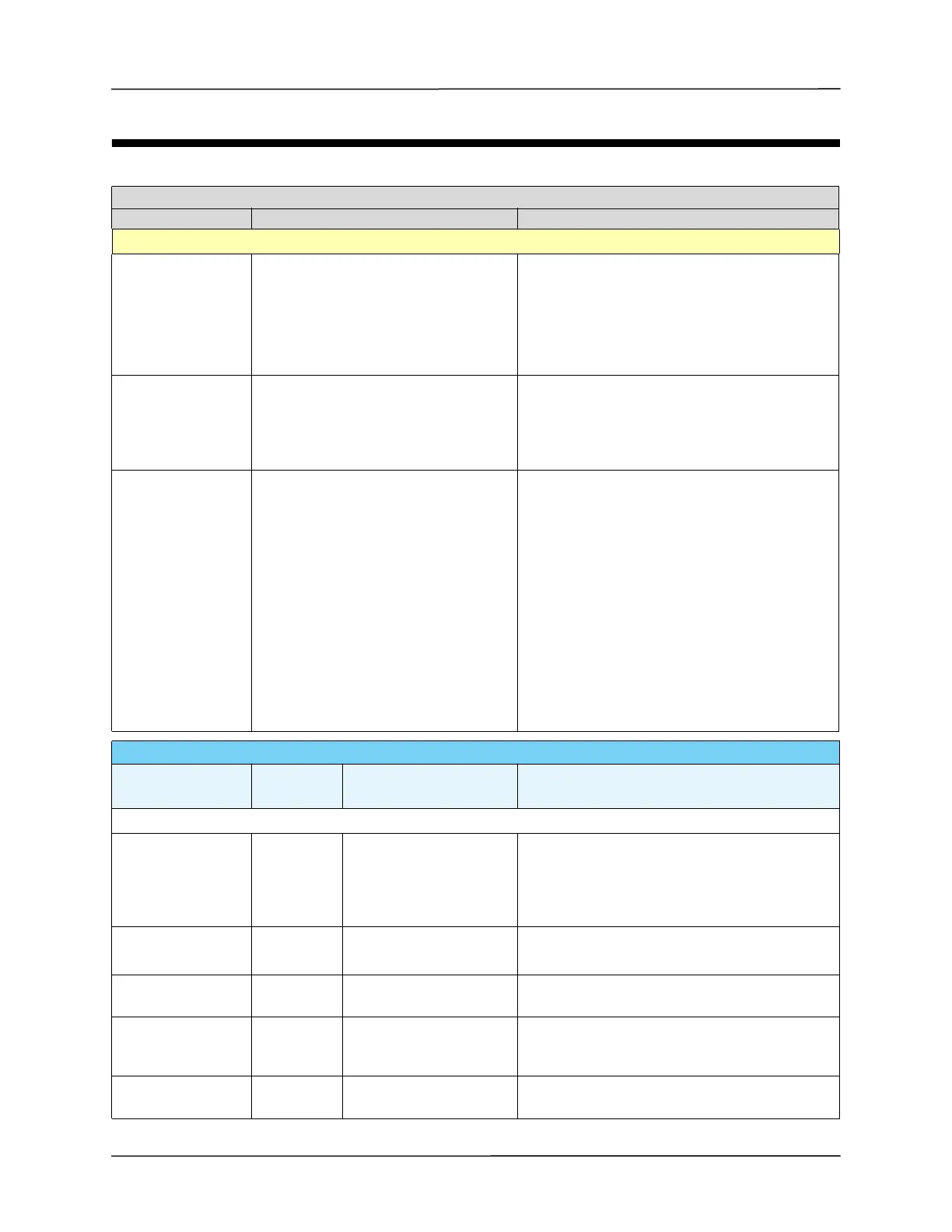

Ventilator Alarms

Title Service

Code

Alarm Purpose Troubleshooting

Self-Check: Transducers/ Calibration Files

Self Check Failure /

Self Check Fault

1001

2001

Indicates a compressor

control fault.

• Cycle Power

• Wet/dirty flow screen

• If the device was used in a high humidity

environment, moisture may condense on the flow

screen.

• Loose compressor connection (electrical)

Self Check Failure /

Self Check Fault

1002

2002

PGA or ADC faults detected

for Compressor System.

• Recalibrate Device

• Replace SPM

Self Check Failure 1003 Alarm occurs if low RPM is

detected.

• Clean or change flow screen

• Check compressor flow

Gas Intake Failure 1030 Gas intake failure, prevents

device from delivering

sufficient flow.

• Check intake assembly for blockage

• Replace filters

Self Check Failure 1174 Flow transducers are not

behaving as expected.

• Change SPM board

Loading...

Loading...