Ventilator & Calibration Troubleshooting

906-0731-04-01 Rev. C ZOLL Ventilator Service Manual 6–29

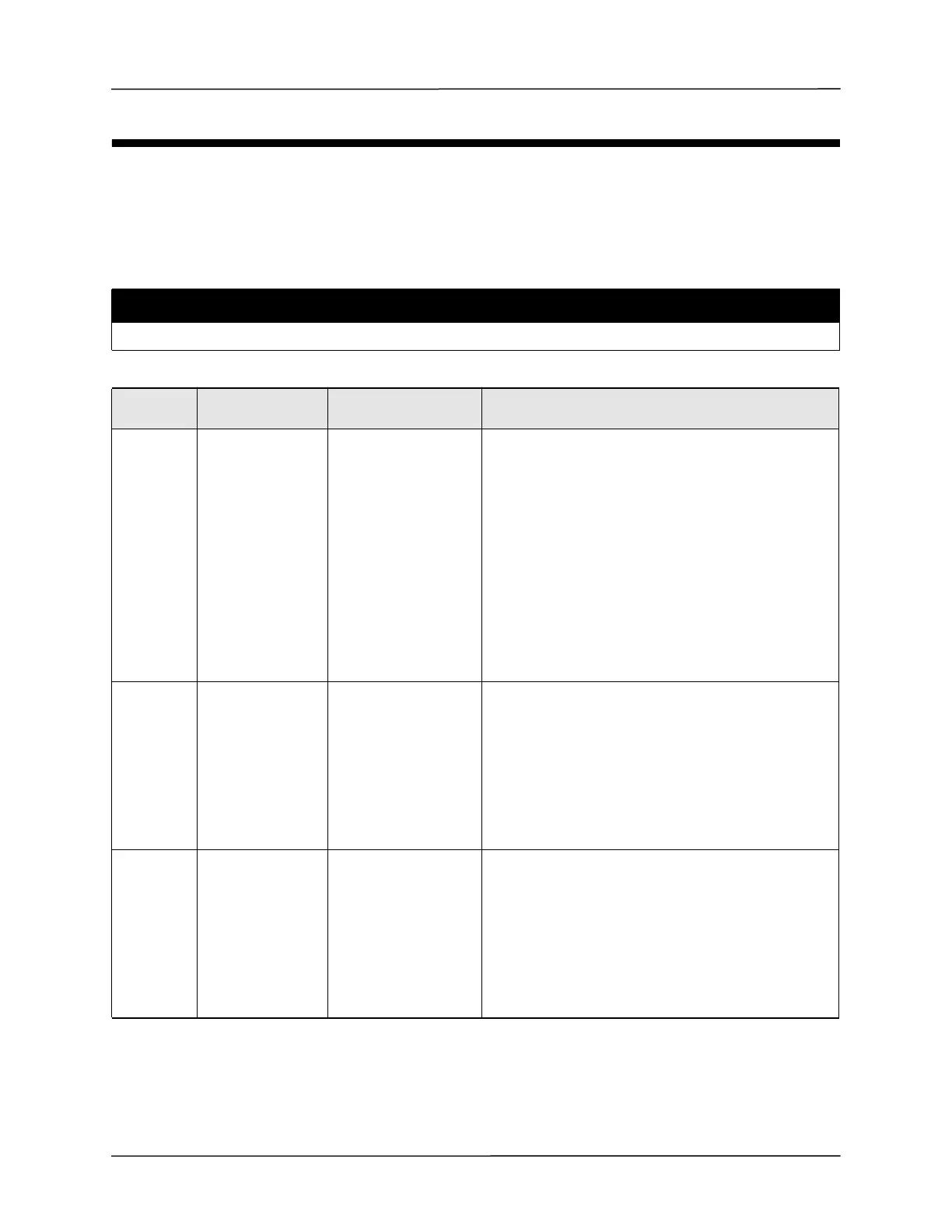

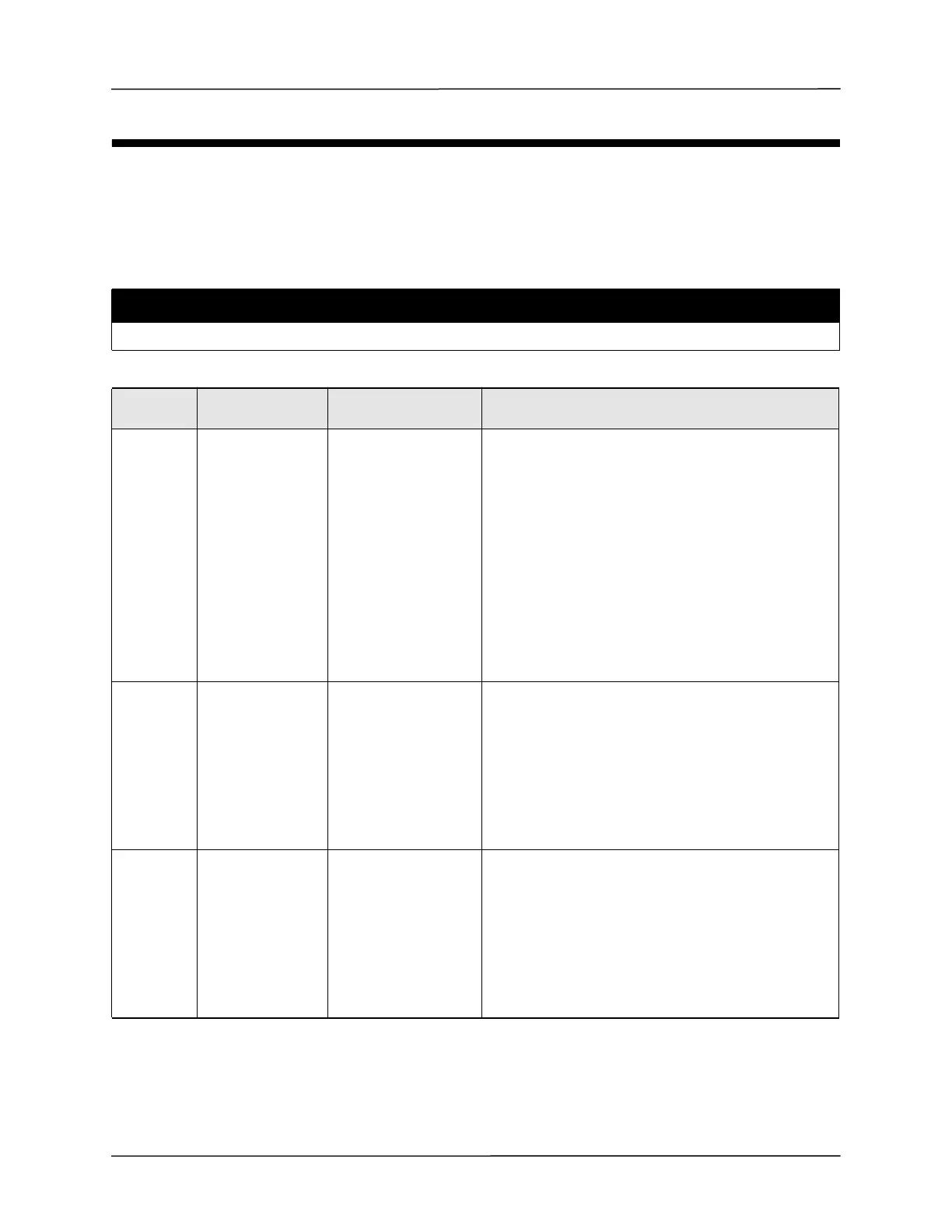

Service Codes - Version 5

A list of all ventilator Service Codes for Version 5follows and is divided into three categories:

• High Priority (1XXX)

• Medium Priority (2XXX)

• Low Priority (3XXX)

Service Codes in each category are provided in numerical order.

NOTE:

Before ordering a service kit, ensure that all troubleshooting steps listed earlier in this chapter have been followed.

CODES NAME

Description /Possible

Cause

Actions

1001

2001

3001

Compressor Flow

Path / Failure

Description:

Compressor does NOT

respond to control

signals

Possible Cause:

• Blocked output

• Tubing kinked

• Connector loose

• Diffuser or flow

screen issue

1. Does not present at power up

• Use Conditions (Possible settings conflict or the output

was blocked during operation):

• Download forensic memory using RCS consult technical

support; possibly the output was blocked.

2. Presents at power up

• Check tubing -> tubing kinked or disconnected-> Correct

tubing

• Check compressor cable is properly seated -> dislodged

connector -> re-seat connector

• Check diffuser screen, check flow screen ->collapsed

diffuser screen or wet flow screen - replace Flow Screen

Kit

1002

2002

3003

Internal

communication

Compressor

(Failure/Faults)

Description:

Compressor flow signal

- High, Low, or Stuck

Possible Cause:

• Tubing kinked or

disconnected

• Faulty compressor

flow transducer

• Check tubing -> tubing kinked or disconnected-> Correct

tubing

• Check Flow transducer -> Bad flow transducer ->

Replace Smart Pneumatic Module (SPM)/ Vent

Assembly Kit

1003 Sensor/

Transducers/Cal

file Failures

Description:

Fails power-on self

check breath

Possible Cause:

• Calibration error

• Foreign substances

in screen

• Faulty compressor

flow transducer

• calibration Error -> Calibrate

• check diffuser screen check flow screen ->collapsed

diffuser screen, foreign substances contamination or

wet flow screen - replace screen

• Bad flow transducer -> Replace SPM Module

Loading...

Loading...