Ventilator & Calibration Troubleshooting

6–14 www.zoll.com 906-0731-04-01 Rev. C

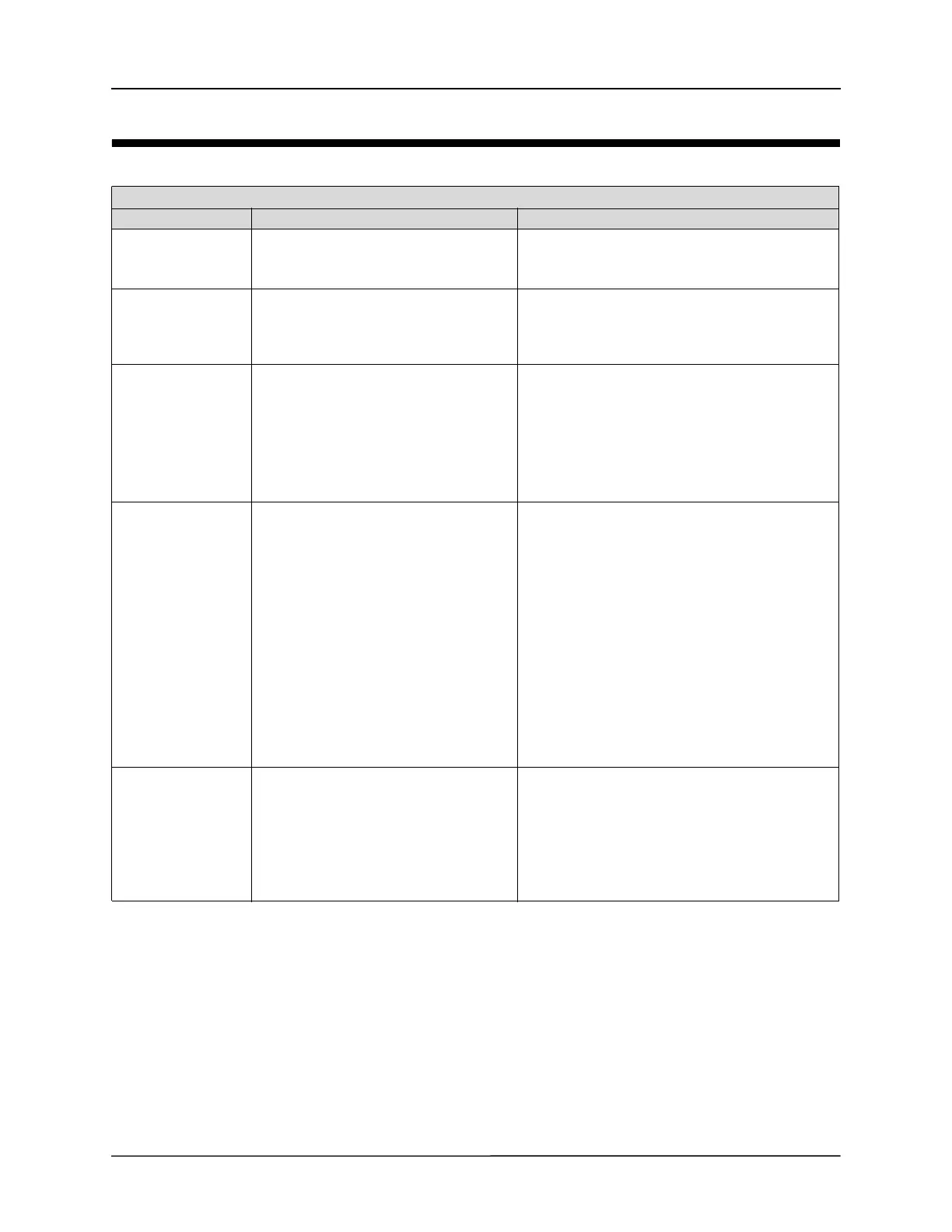

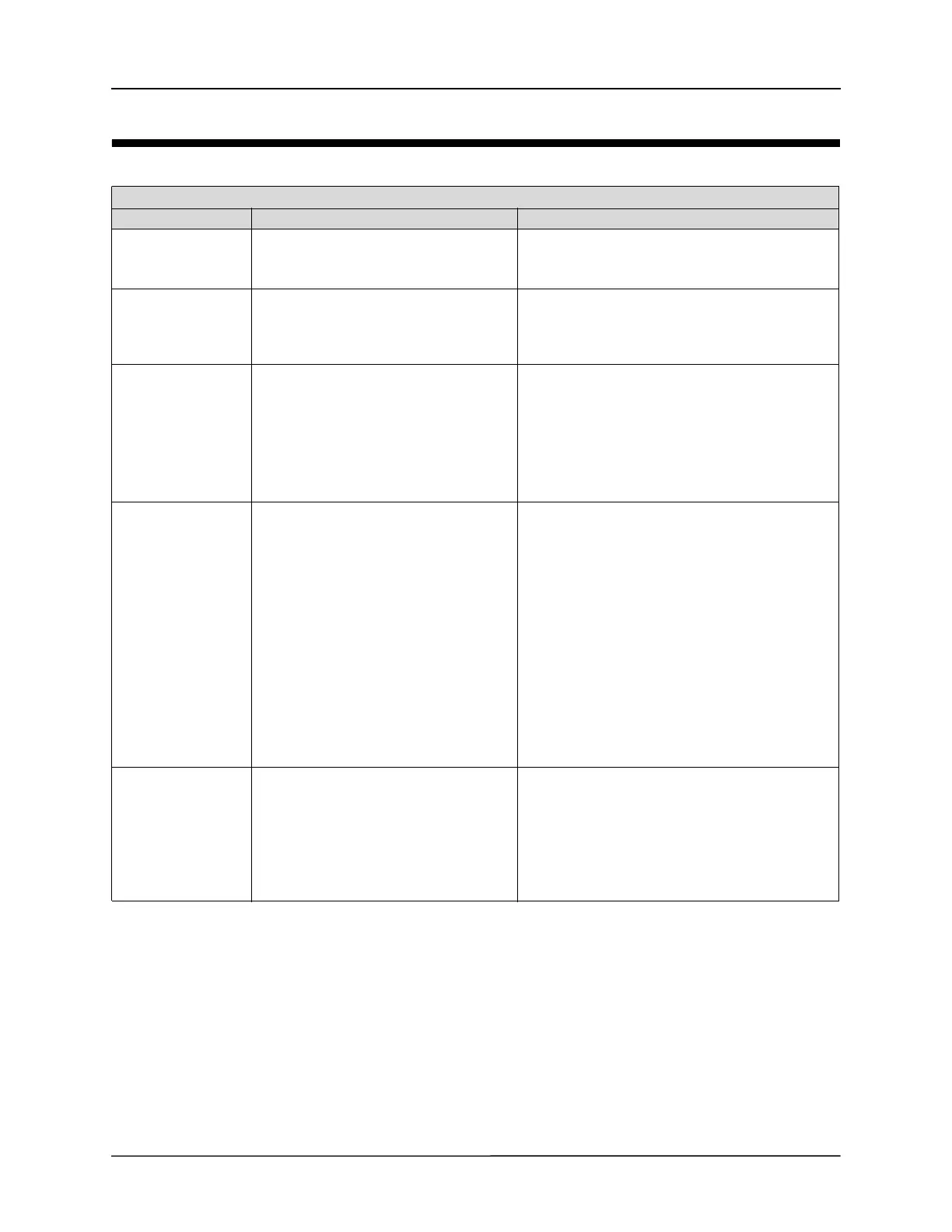

Troubleshooting — Smart Pneumatic Module (SPM) Hardware

Remote Calibration System

Discrete Tests Purpose Troubleshooting

SPM Communication The test confirms communication signals (RX

& TX), bootload and toggle (set/reset) are

functional prior to calibration.

• Review active service codes refer to the Service

code troubleshooting section.

SPM Self Check The device software continuously checks to

see that the hardware has not failed. The SPM

software checks for alarms. In event an alarm

is active, and the TCE indicates a failure.

• Review active service codes refer to the Service

code troubleshooting section.

SPM Blink Confirms the SPM is able to drive the LED’s

and Buzzer in the event the EMV is not

functioning.

Operator confirmation that Red LED's and

buzzer were driven within 15 seconds (Test

Passed = Pass), otherwise Test Passed = Fail

• Failure of this test may be the SPM board faulty or

connections to the SPM

• Check the SPM to UIM cable, the PIM to CPU cable,

PIM to SPM cable.

• Change the SPM Assembly.

O2 Leak and Filter

Check

The O2 system is checked for leaks.

• Input pressure limit is +/- 1 psi at 90 psi

• Input pressure limit is +/- 10% at 70 psi

• Leak rate is less than or equal 2000 ml/

hour at 55 psi.

• Sintered bronze filter resistance measured

at 100 LPM flow is between 0.01 and 0.06

psi/LPM.

• Reported O2 supply pressure limit is <2 psi

for zero, and <7 psi for 70 psi.

• Reported O2 Leak through valve limit is

less than or equal 0.3 LPM

1. If this is a failure, verify the O2 supply pressure.

Check O2 input barb. Check internal O2 tubing.

Check for damage or debris at the input filter.

2. If this is a failure check tubing. Check O-ring on O2

inlet assembly, O2 manifold, and O2 valve. Replace

O2 manifold and O-rings

3. If this is a failure, replace the sintered bronze filter

assembly

4. Check O2 supply, If this is a failure, check for kinked

or damaged tubing. Replace the Smart Pneumatic

Module (SPM)/ Vent Assembly Kit.

5. If this test fails check for kinked or damaged tubing,

Check for audible leak. Change the O2 valve.

Manifold Leak Test The system is pressurized (within

specification) to determine if there are any

leaks in the manifold connection or tubing.

The slope of the airway pressure during

simulated expiratory phase (no flow) shall be

less than 0.5 cmH2O per second at 5 cmH2O

and 25 cmH2O.

• Check test setup for leaks, check for deformation of

the test lung

• Checks for leaks between compressor/O2 Valve

output and gas output port.

• See the manifold calibration sheet.

Loading...

Loading...