302 Parameters

40.34 Set 1 derivation

time

Defines the derivation time of the process PID controller. The

derivative component at the controller output is calculated on

basis of two consecutive error values (E

K-1

and E

K

) according

to the following formula:

PID DERIV TIME × (E

K

- E

K-1

)/T

S

, in which

T

S

= 2 ms sample time

E = Error = Process reference - process feedback.

0.000 s

0.000…10.000 s Derivation time. 1000 = 1 s

40.35 Set 1 derivation

filter time

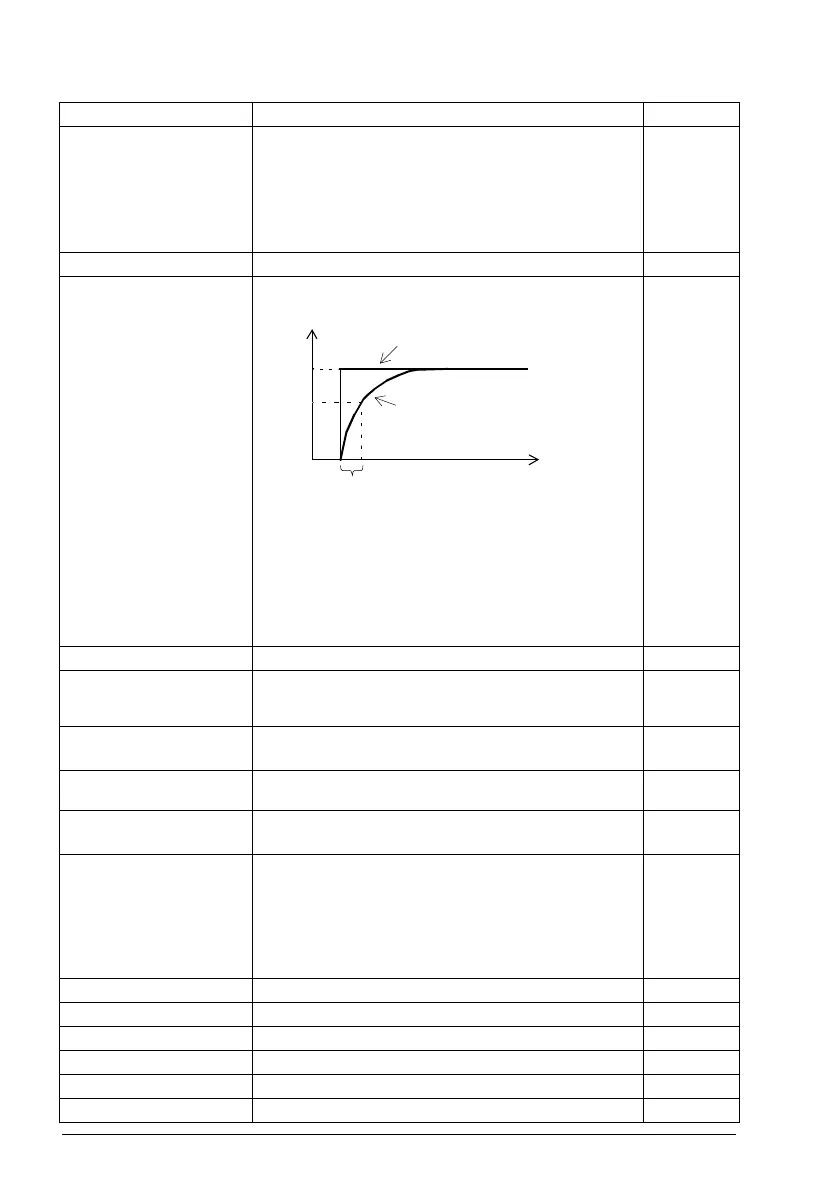

Defines the time constant of the 1-pole filter used to smooth

the derivative component of the process PID controller.

0.0 s

0.0…10.0 s Filter time constant. 10 = 1 s

40.36 Set 1 output min Defines the minimum limit for the process PID controller

output. Using the minimum and maximum limits, it is possible

to restrict the operation range.

0.0

-200000.00

…200000.00

Minimum limit for process PID controller output. 1 = 1

40.37 Set 1 output max Defines the maximum limit for the process PID controller

output. See parameter 40.36 Set 1 output min.

100.0

-200000.00

…200000.00

Maximum limit for process PID controller output. 1 = 1

40.38 Set 1 output freeze Freezes (or defines a source that can be used to freeze) the

output of the process PID controller, keeping the output at the

value it was before freeze was enabled. This feature can be

used when, for example, a sensor providing process

feedback must to be serviced without stopping the process.

1 = Process PID controller output frozen

See also parameter 40.30 Set 1 setpoint freeze enable.

Not selected

Not selected Process PID controller output not frozen. 0

Selected Process PID controller output frozen. 1

DI1 Digital input DI1 (10.02 DI delayed status, bit 0). 2

DI2 Digital input DI2 (10.02 DI delayed status, bit 1). 3

DI3 Digital input DI3 (10.02 DI delayed status, bit 2). 4

DI4 Digital input DI4 (10.02 DI delayed status, bit 3). 5

No. Name/Value Description Def/FbEq16

63

%

100

T

t

O = I × (1 - e

-t/T

)

I = filter input (step)

O = filter output

t = time

T = filter time constant

Unfiltered signal

Filtered signal

Loading...

Loading...