42/24-10 EN Rev. 9 Chapter 9: Inspection and Maintenance 9-15

Limas11: Safety Cell Cleaning

Description of the

Safety Cell

The safety cell comprises three components:

• Sample cell of stainless steel 1.4571,

• Beam guide tube 1 of brass (on the side pointing to the beam splitter),

• Beam guide tube 2 of brass (on the side pointing to the measuring detector).

The beam guide tubes are screwed into the sample cell and press the cell windows

against the chambered 22.1x1.6 FFKM70 O-ring seals. In this manner, the sample

gas side of the cell is sealed so that it is gas-tight. One 28x2-FKM80 O-ring seal is

located on the periphery of each of the beam guide tubes. The purge gas chamber

is sealed so that it is gas-tight to the outside by means of this seal.

The tightness of the sample cell has been tested in the factory for a leakage rate

of < 1 x 10

–6

mbar l/s.

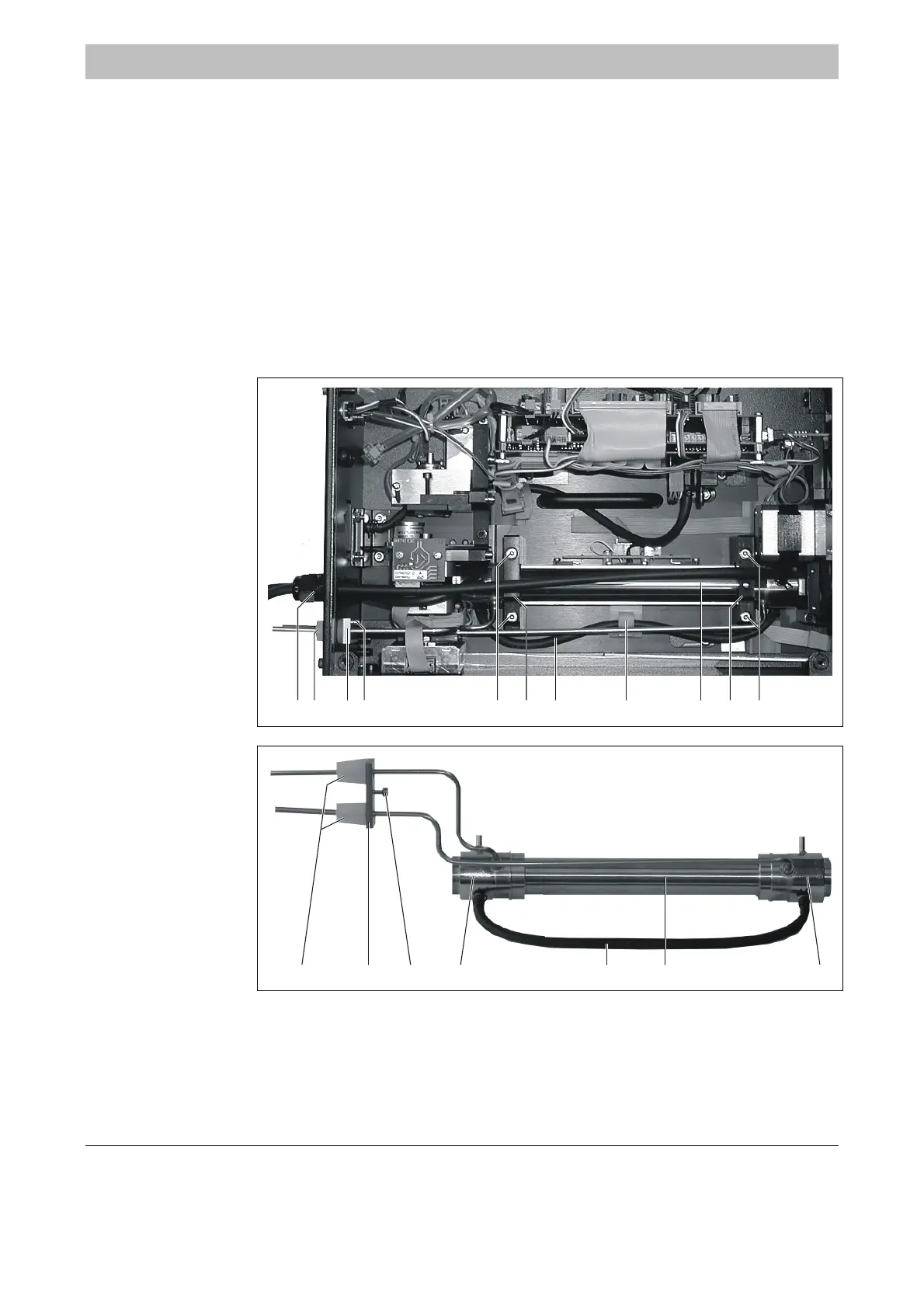

Fig. 9-9

Safety Cell

in th e L imas11

Analyzer Module

4

1

7

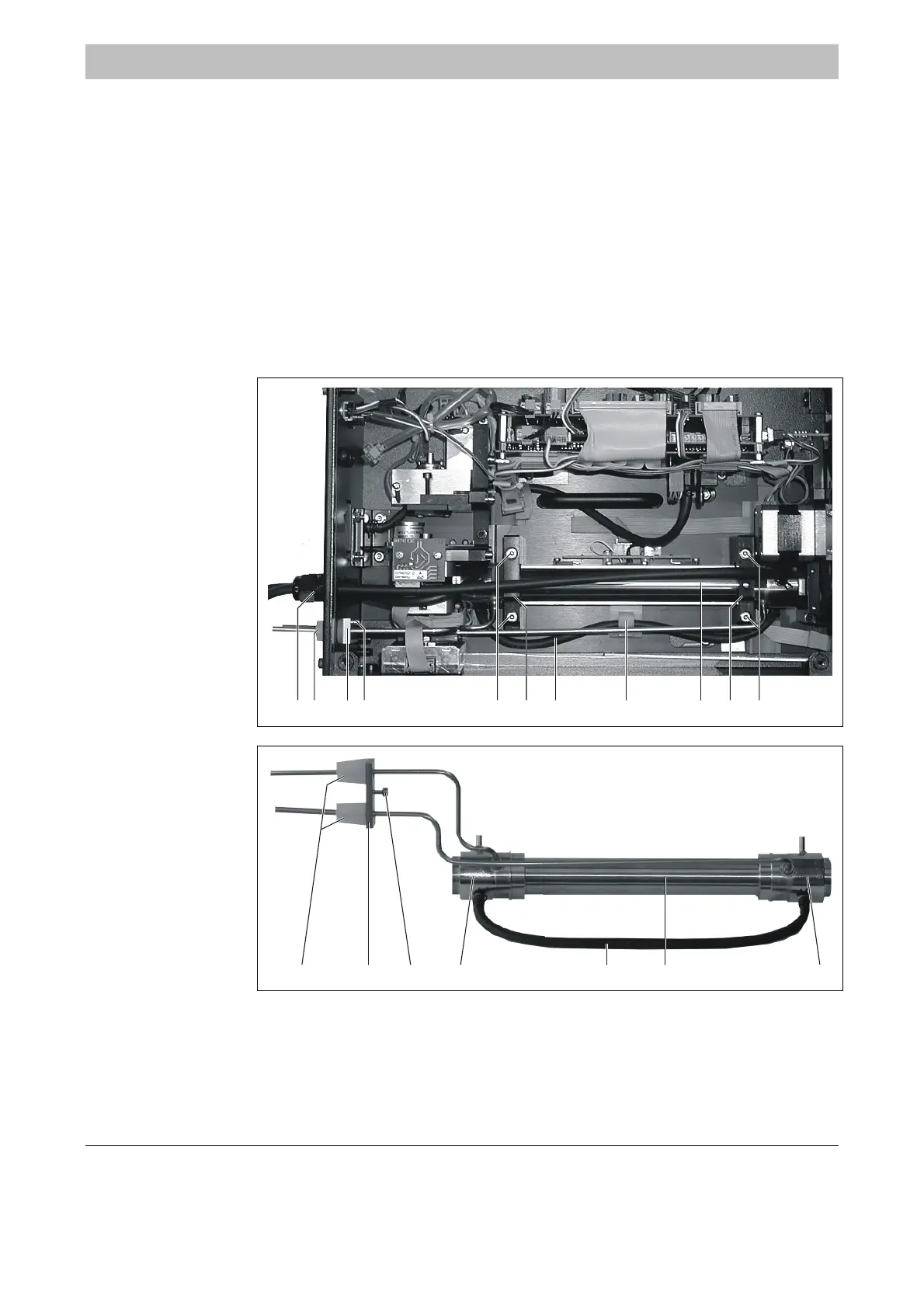

Fig. 9-10

Safety Cell

1

11

4

1 Couplings of the

Purge Gas Lines

2 Plugs

3 Retaining Board

4 Screw

5 Screws

6 Mounting Bracket

7 Purge Gas Hose

8 Fixing Device

9 Sample Cell

10 Beam Guide Tube

11 Beam Guide Tube

Continued on next page

Loading...

Loading...