A-2-4 Appendix 2: Analyzer Module Operating Specifications 42/24-10 EN Rev. 9

Magnos206 Operating Specifications

Linearity deviation ≤ 0.5 % of span

Repeatability ≤ 50 ppm O

2

(time base for gas exchange ≥ 5 minutes)

Zero drift ≤ 3 % of span of the smallest measurement range (per order) per week, minimum

300 ppm O

2

per week; following prolonged transport and storage time the drift

can be higher during the first weeks of operation.

Sensitivity drift ≤ 0.1 % Vol.-% O

2

per week or ≤ 1 % of measured value per week (not cumulative),

the smaller value applies; ≤ 0.25 % of measured value per year

Output fluctuation (2 σ) ≤ 25 ppm O

2

at electronic T90 time (static/dynamic) = 3 /0 sec.

Detection limit (4 σ) ≤ 50 ppm O

2

at electronic T90 time (static/dynamic) = 3 /0 sec.

Flow influence ≤ 0.1 Vol.-% O

2

in permissible range

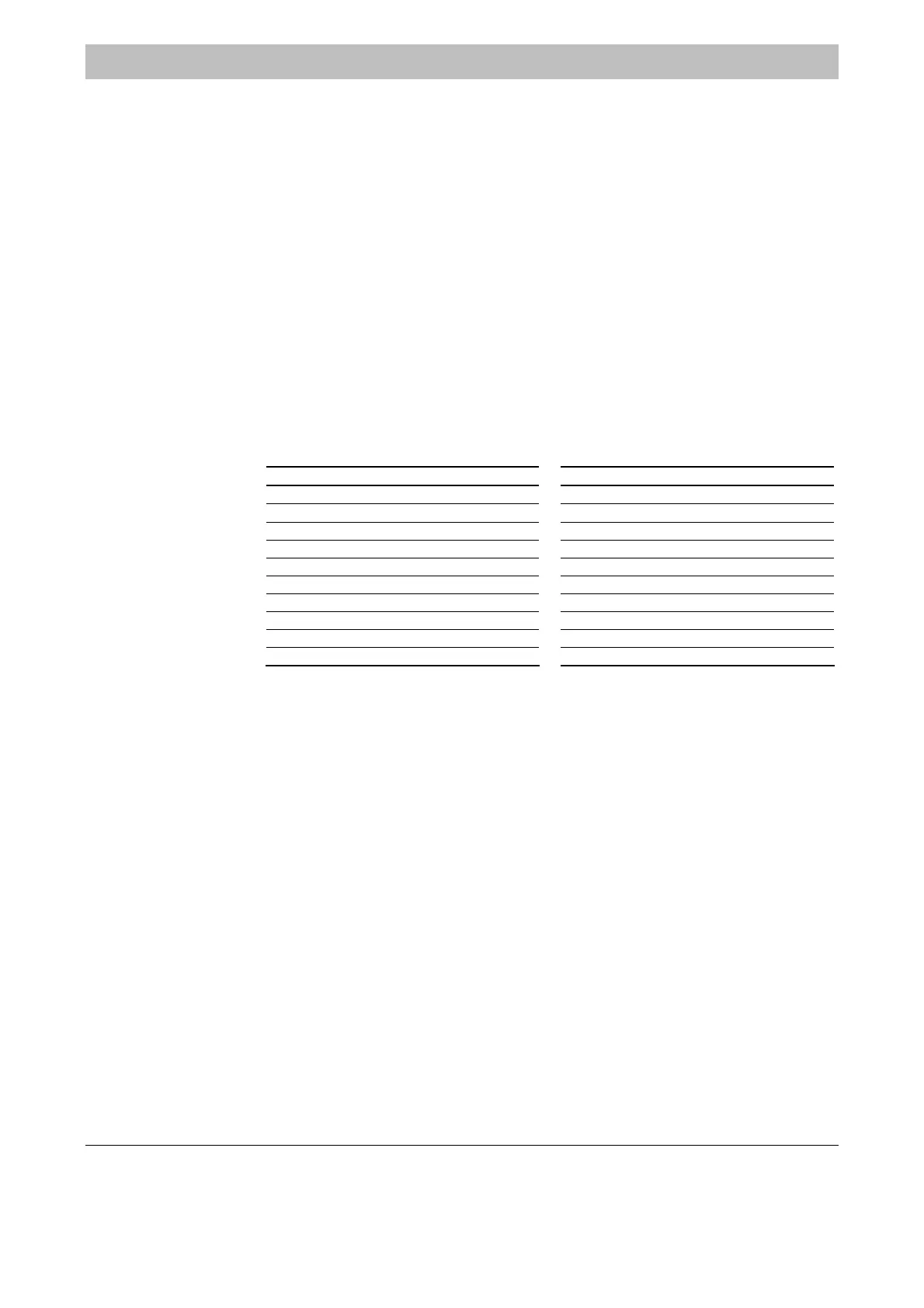

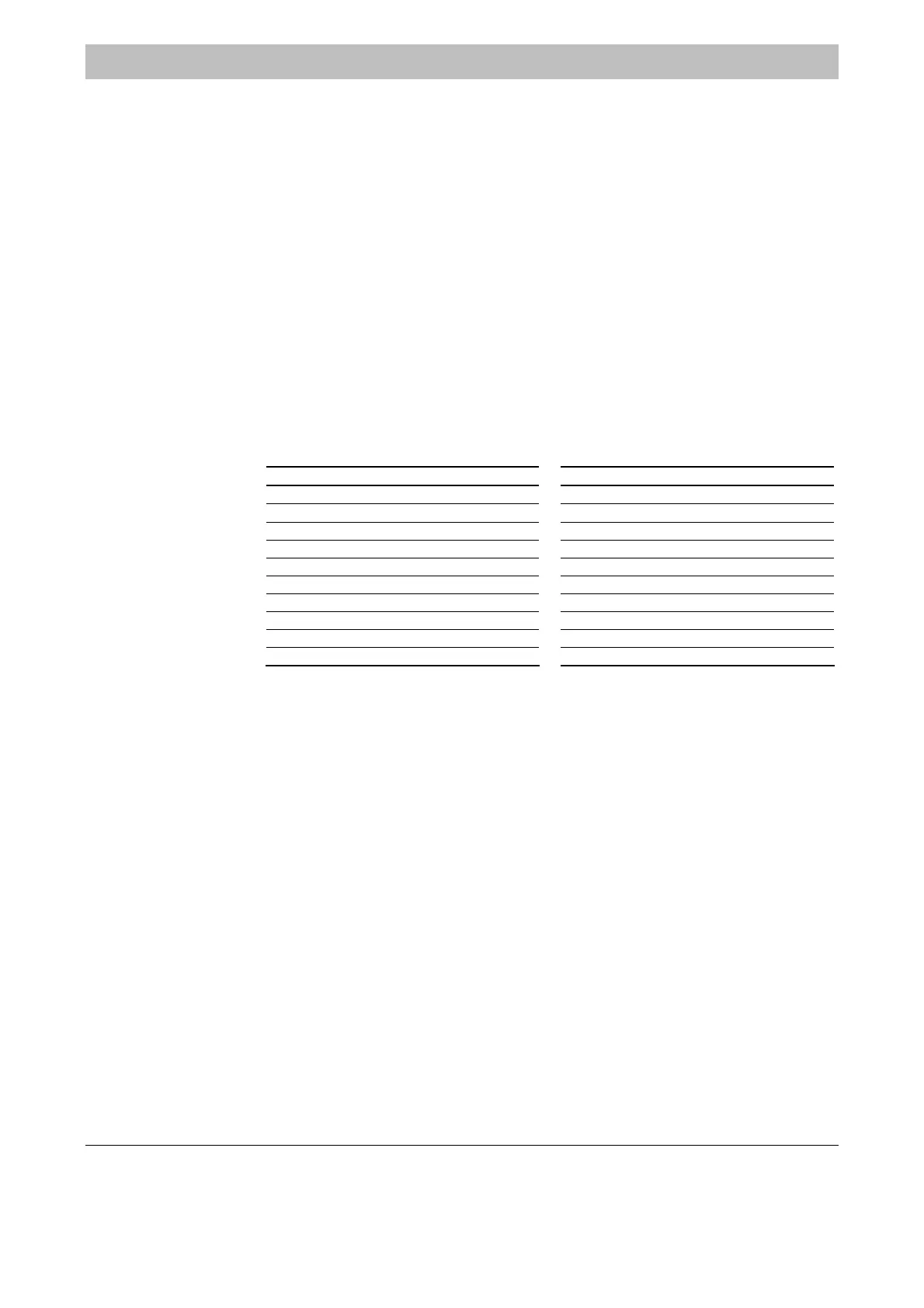

Associated gas

influence

The effect of associated gases with a concentration of 100 Vol.-% as a shift of the

zero-point (ΔZero) in Vol.-% O

2

can be estimated using the guidelines in the

following table:

Associated Gas Concentr. 100 Vol.-% ΔZero Associated Gas Concentr. 100 Vol.-% ΔZero

Hydrogen H

2

+0.28 Carbon dioxide CO

2

–0.32

Hydrogen sulfide H

2

S –0.45 Carbon oxysulfide COS –0.90

Argon Ar –0.26 Ethane C

2

H

6

–0.46

Helium He +0.30 Ethylene C

2

H

4

–0.29

Neon Ne +0.13 Methane CH

4

–0.24

Nitrogen N

2

0.00 Propane C

3

H

8

–0.98

Nitrogen oxide NO +43.00 Propylene C

3

H

6

–0.55

Nitrogen dioxide NO

2

+28.00 Trichloroethylene C

2

HCl

3

–2.17

Nitrous oxide N

2

O –0.20 Vinylchloride CH

2

CHCl –0.75

Carbon monoxide CO –0.01 For further associated gases refer to EN 61207-3

Temperature

influence

• At zero-point: ≤ 0.02 Vol.-% O

2

per 10 °C

• On sensitivity: ≤ 0.1 % of measured value per 10 °C

Ambient temperature in permissible range, thermostat temperature = 64 °C

Air pressure influence • At zero-point: no influence effect

• On sensitivity without pressure correction: ≤ 1 % of measured value per 1 % air

pressure change

• On sensitivity with pressure correction by means of internal pressure sensor

(option): ≤ 0.1 % of measured value per 1 % pressure change; for highly

suppressed measurement ranges ≤ 0.01 % of measured value per 1 % pressure

change or ≤ 0.002 Vol.-% O

2

per 1 % pressure change, whichever is greater.

Pressure sensor working range: p

abs

= 600 to 1250 hPa

Power supply

influence

24 VDC ± 5 %: ≤ 0.4 % of span

Position influence Zero-point shift ≤ 0.05 Vol.-% O

2

per 1° deviation from horizontal orientation.

Position has no effect on the hard-mounted unit.

T

90

time T

90

≤ 3.5 to 10 sec. at sample gas flow = 90 l/h and electronic T90 time (static/

dynamic) = 3/ 0 sec., gas switching from N

2

to air (applies to a gas analyzer with

one analyzer module)

Loading...

Loading...