Mounting

30 FEX300, FEX500 OI/FEX300/FEX500-EN

Change from one to two colu mns

4.5 Installation Requirements

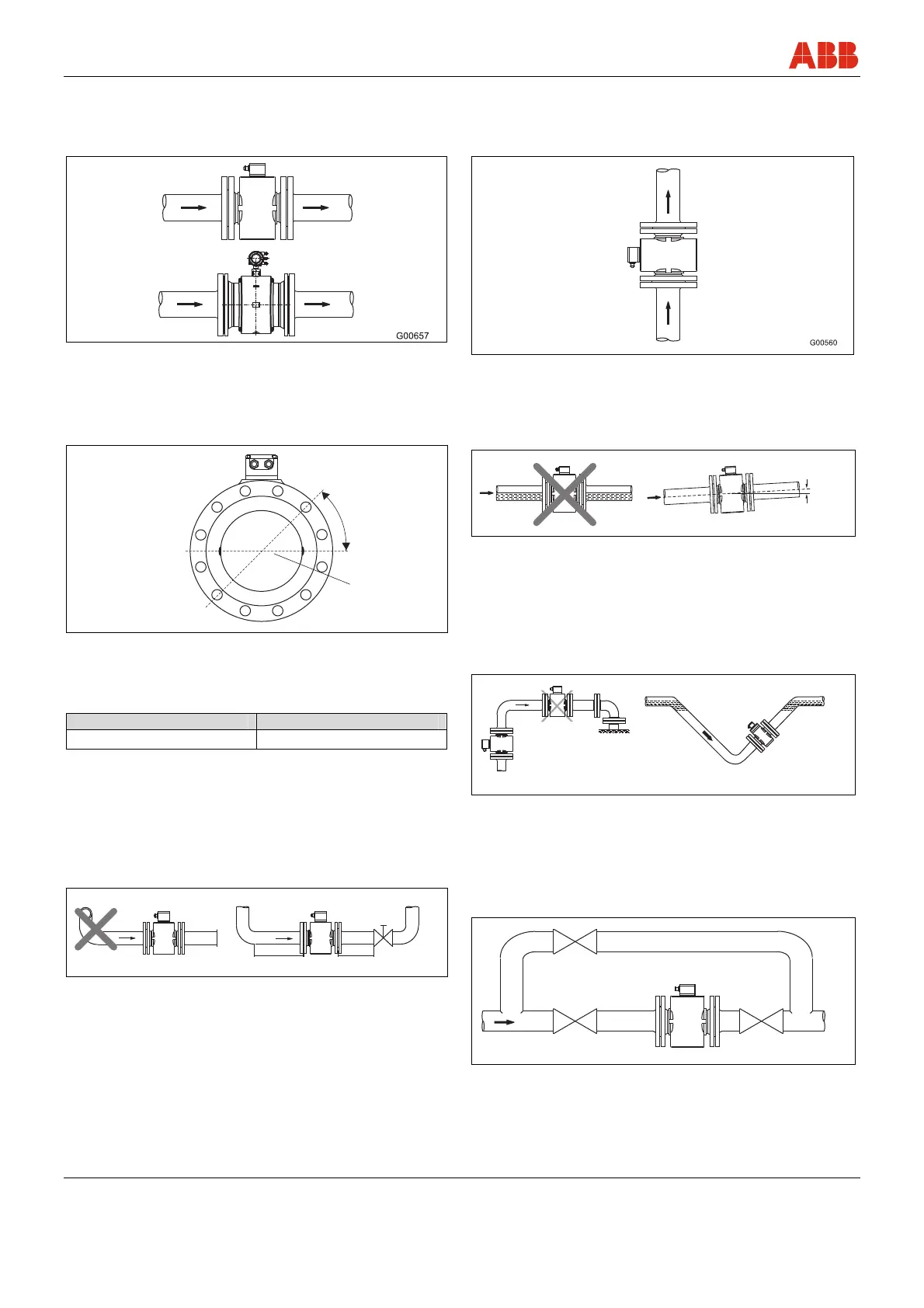

The device measures the flowrate in both directions. Forward flow is

the factory setting, as shown in Fig. 13.

Fig. 13

4.5.1 Electrode axis

Electrode axis (1) should be horizontal if at all possible or no more

that 45° from horizontal.

G00041

max. 45°

1

Fig. 14

4.5.2 In- and outlet pipe sections

Straight inlet section Straight outlet section

3 x DN 2 x DN

DN = Flowmeter sensor size

• Do not install fittings, manifolds, valves etc. directly in front of the

meter tube (1).

• Butterfly valves must be installed so that the valve plate does not

extend into the flowmeter sensor.

• Valves or other turn-off components should be installed in the

outlet pipe section (2).

• For compliance with the measuring accuracy, observe the inlet

and outlet pipe sections.

G00037

1

2

3xDN

2xDN

Fig. 15

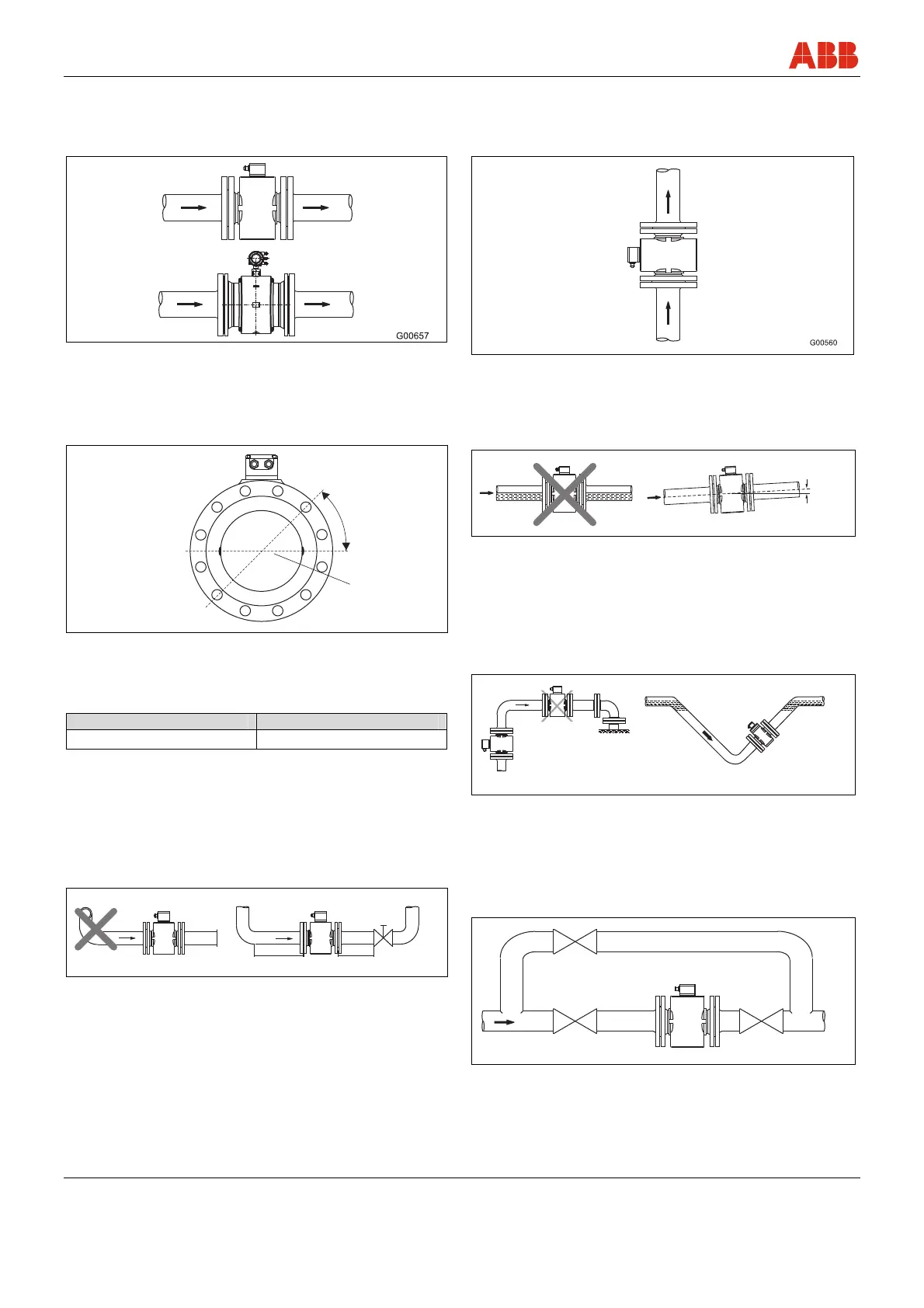

4.5.3 Vertical connections

• Vertical installation for measurement of abrasive fluids, flow

preferably from below to above.

Fig. 16

4.5.4 Horizontal connections

• Meter tube must always be completely full.

• Provide for a slight incline of the connection for degassing.

G00038

3°

Fig. 17

4.5.5 Free inlet or outlet

• Do not install the flowmeter at the highest point or in the draining-

off side of the pipeline, flowmeter runs empty, air bubbles can

form (1).

• Provide for a siphon fluid intake for free inlets or outlets so that

the pipeline is always full (2).

G00040

1

2

Fig. 18

4.5.6 Strongly contaminated fluids

• For strongly contaminated fluids, a bypass connection according

to the figure is recommended so that operation of the system can

continue to run without interruption the during the mechanical

cleaning.

G00042

Fig. 19

Loading...

Loading...