FSM4000 ELECTROMAGNETIC FLOWMETER | OI/FSM4000-EN REV. E 17

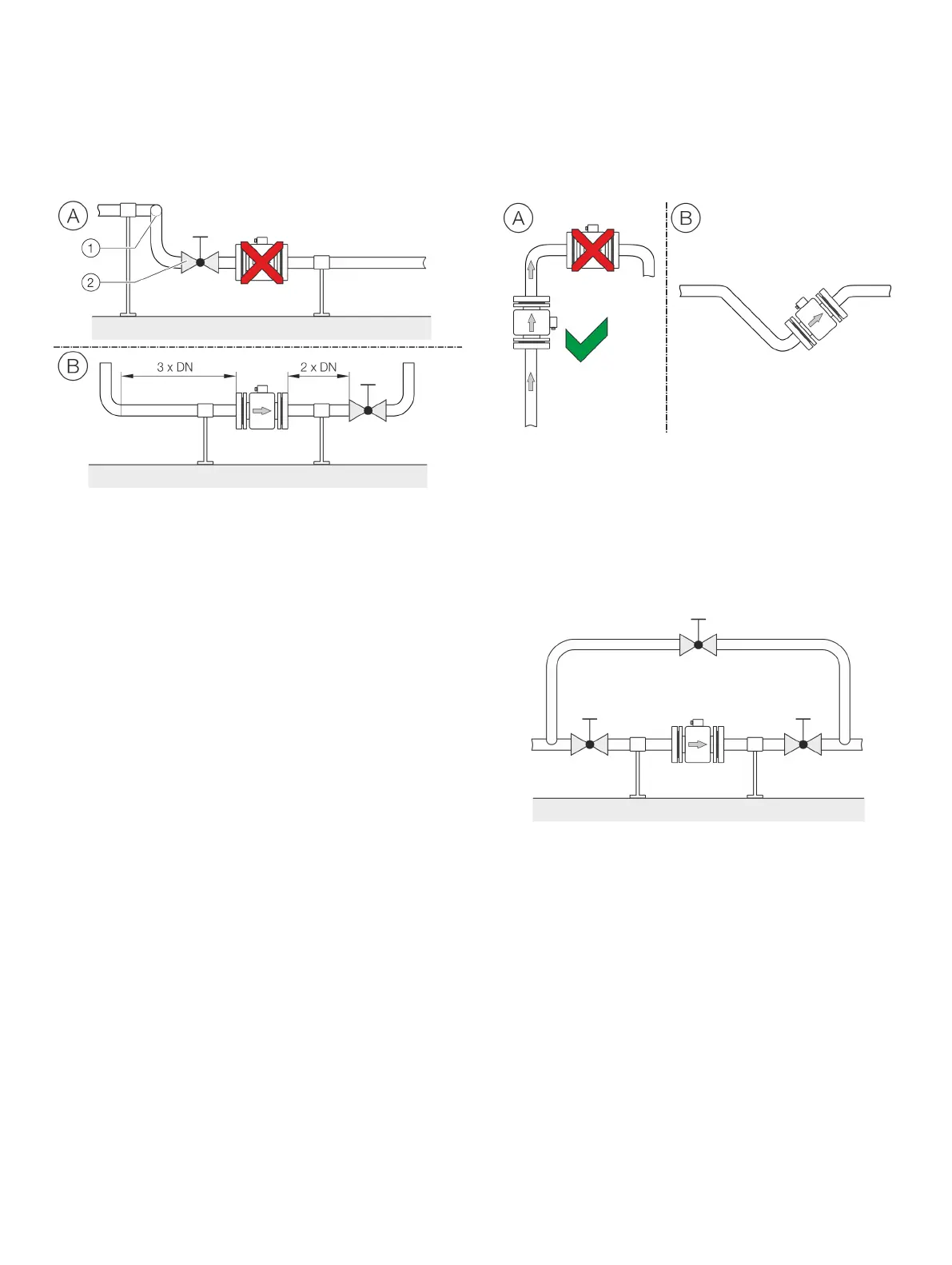

Inlet and outlet sections

Double manifold

Turn-off device

Figure 15: Inlet and outlet section, turn-off devices

The measuring principle is independent of the flow profile as

long as standing eddies do not extend into the measured value

formation, such as may for example occur after double

manifolds, in the event of tangential inflow, or where half-open

gate valves are located upstream of the sensor. In such cases,

measures must be put in place to normalize the flow profile.

A Do not install fittings, manifolds, valves, etc., right before the

flowmeter sensor.

B Inlet / outlet sections: length of the straight piping upstream

and downstream on the sensor.

Experience has shown that, in most installations, straight

inlet sections 3 × DN long and straight outlet sections 2 × DN

long are sufficient (DN = nominal diameter of the flowmeter

sensor).

For test stands, the reference conditions of 10 × DN straight

inlet and 5 × DN straight outlet must be provided, in

accordance with EN 29104 / ISO 9104.

Valves or other turn-off devices should be installed in the

outlet section.

Valve flaps must be installed so that the valve damper plate

does not extend into the flowmeter sensor.

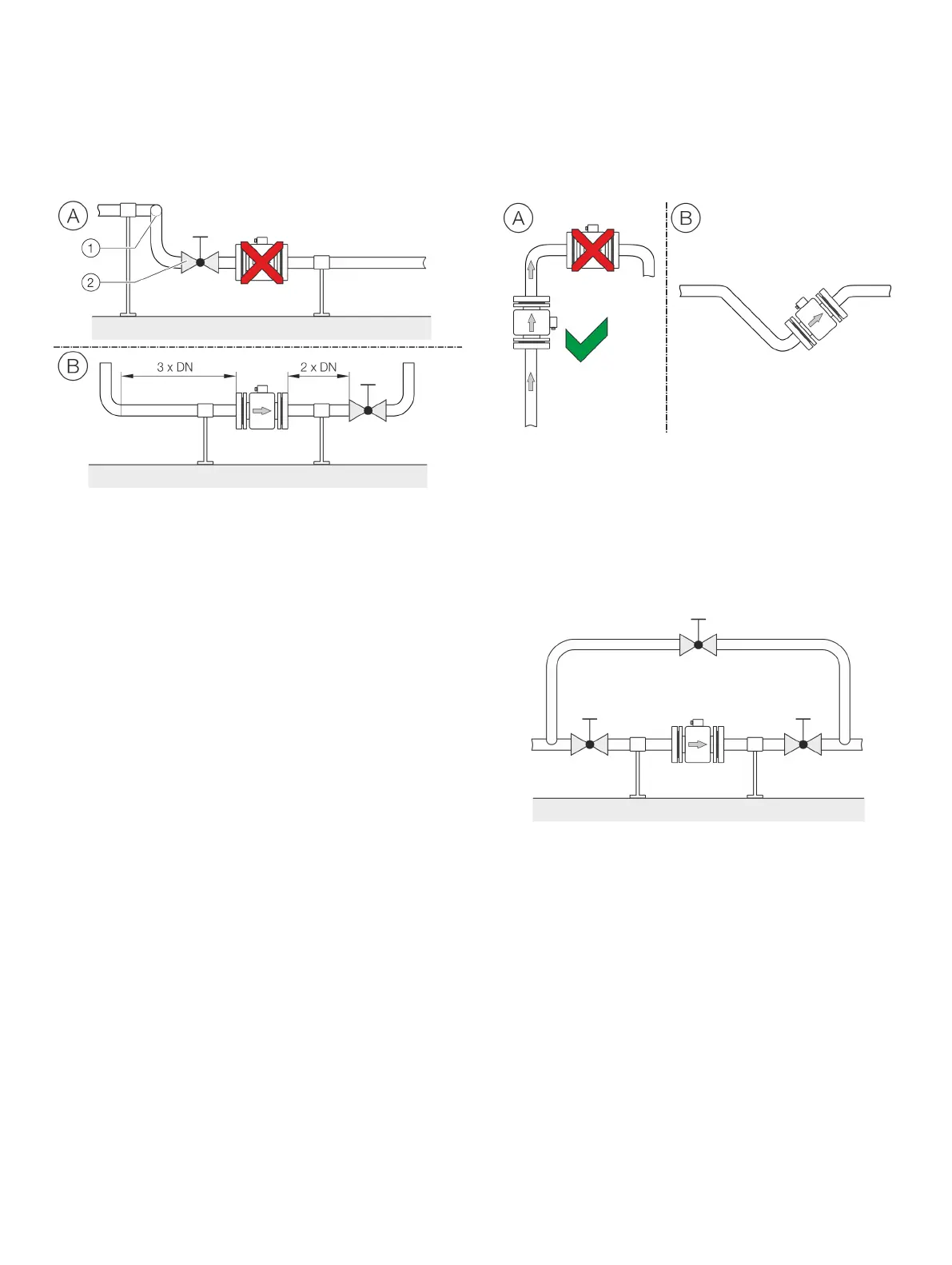

Free inlet or outlet

Figure 16: Free inflow and outflow

A For a free outflow, do not install flowmeter at the highest

point of the piping or on its outflow side, since the

measuring tube may run empty, creating air bubbles.

B For free inflow/outflow, provide an invert to make sure that

the piping is always full

Mounting with heavily contaminated measuring media

Figure 17: Bypass line

For strongly contaminated measuring media, a bypass line in

accordance with the figure is recommended so that operation of

the system can continue to run without interruption during

mechanical cleaning.

Loading...

Loading...