FSM4000 ELECTROMAGNETIC FLOWMETER | OI/FSM4000-EN REV. E 15

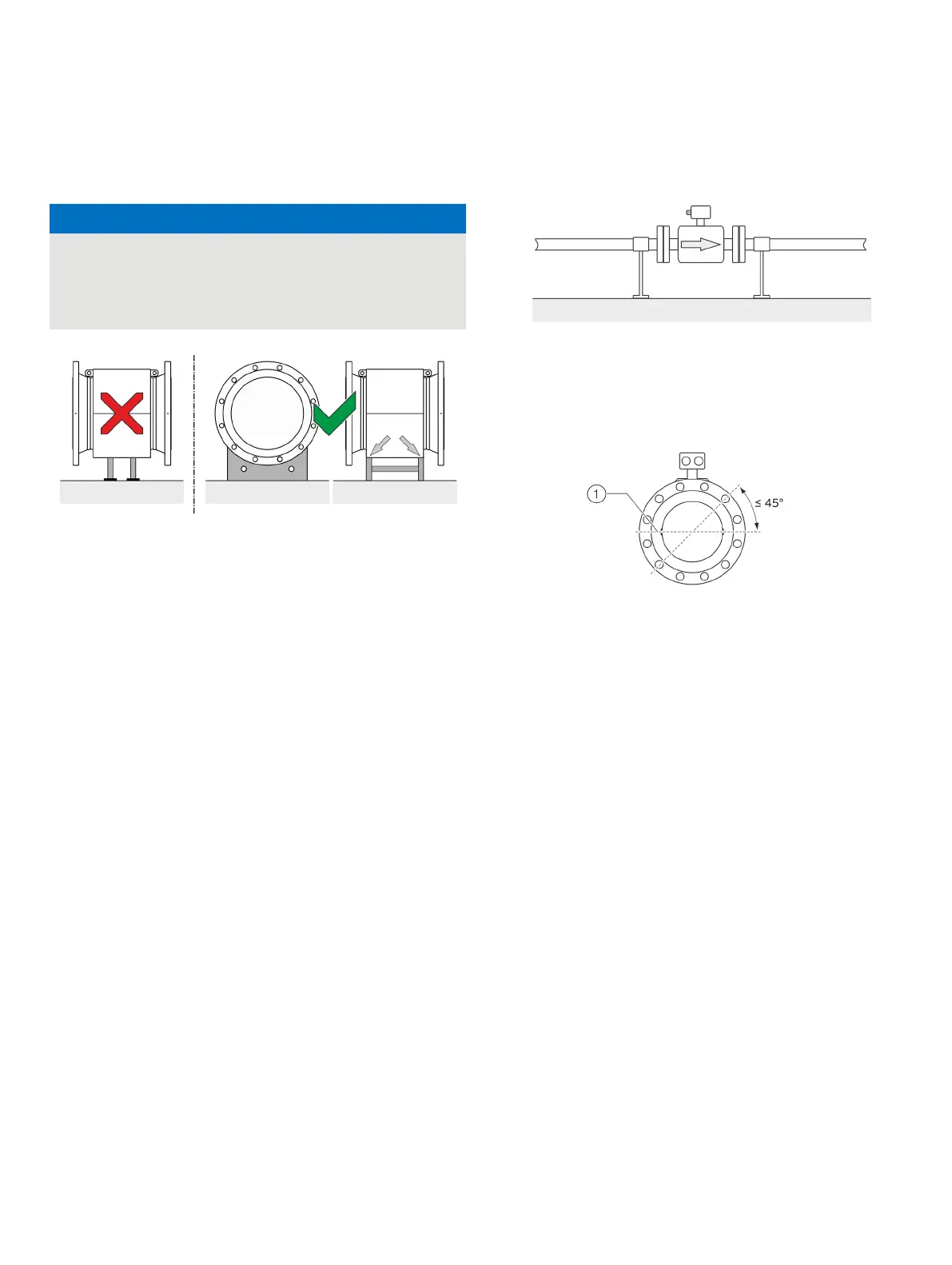

Brackets

Potential damage to the device!

Improper support for the device may result in a deformed

housing and damage to internal magnetic coils.

• Place the supports at the edge of the sensor housing (see

Figure 10: Support for nominal diameters greater than DN 400

Devices with nominal diameters larger than DN 400 must be

mounted on a sufficiently strong foundation with support.

Gaskets

The following points must be observed when installing gaskets:

• To achieve the best results, make sure that the gaskets

and meter tube fit concentrically.

• To make sure that the flow profile is not distorted, the

gaskets may not intrude in the piping cross-section.

• The use of graphite with the flange or process connection

gaskets is prohibited. This is because, in some instances,

an electrically conductive coating may form on the inside

of the meter tube.

Devices with hard rubber or soft rubber liner

• Devices with a hard / soft rubber liner always require

additional gaskets

• ABB recommends using gaskets made from rubber or

rubber-like sealing materials

• When selecting the gaskets, make sure that the tightening

torques specified in chapter Torque information on page 21

are not up-scaled.

Devices with a PTFE, PFA or ETFE liner

• In principle, devices with a PTFE, PFA or ETFE liner do not

require additional gaskets.

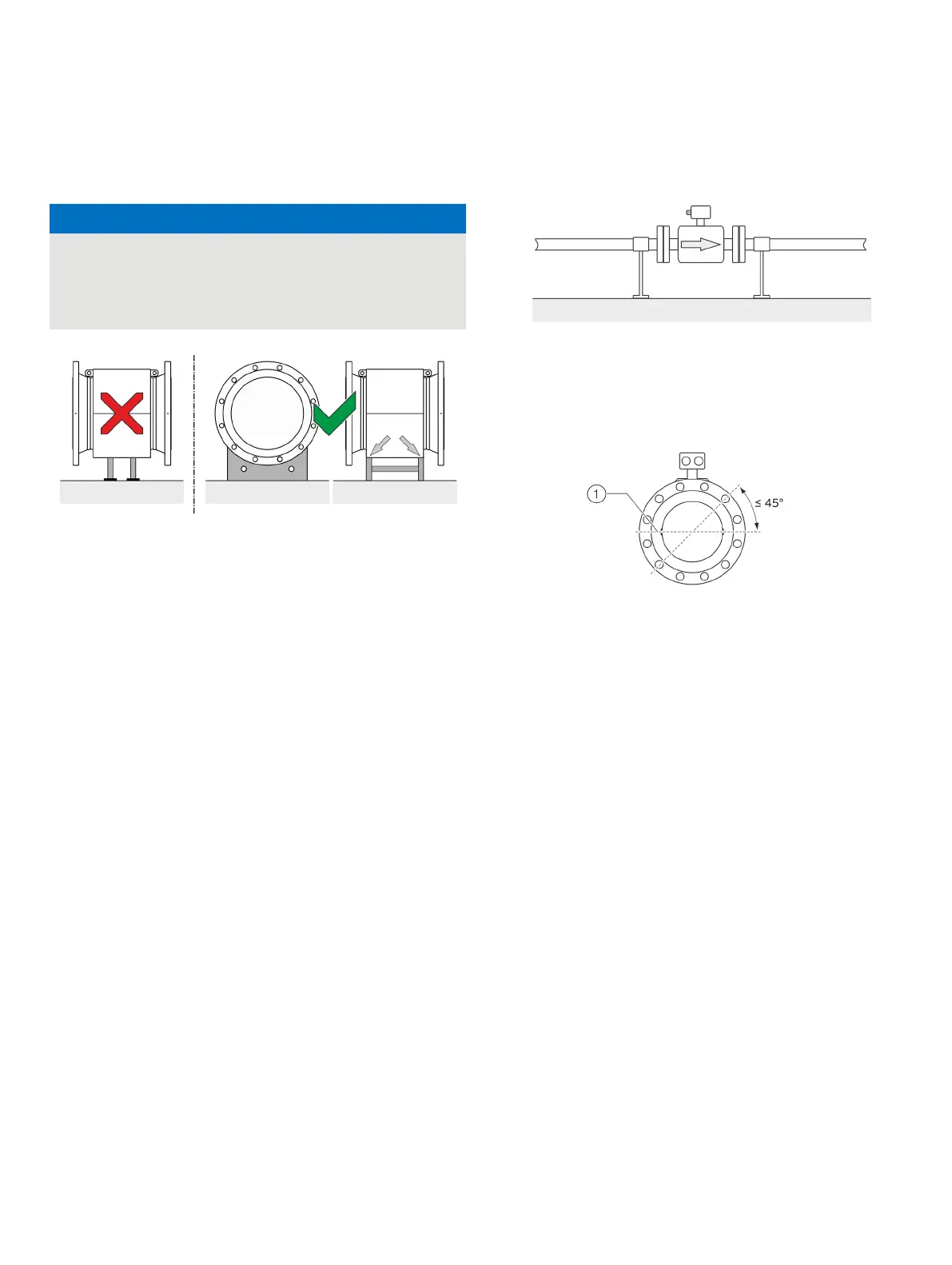

Flow direction

Figure 11: Flow direction

The device measures the flow rate in both flow directions.

Forward flow is the factory setting, as shown in Figure 11.

Electrode axis

Electrode axis

Figure 12: Orientation of the electrode axis

The flowmeter sensor should be mounted in the piping in such a

manner that the electrode axis is oriented as horizontally as

possible.

A maximum deviation of 45° from the horizontal position is

permissible.

Loading...

Loading...