FSM4000 ELECTROMAGNETIC FLOWMETER | OI/FSM4000-EN REV. E 19

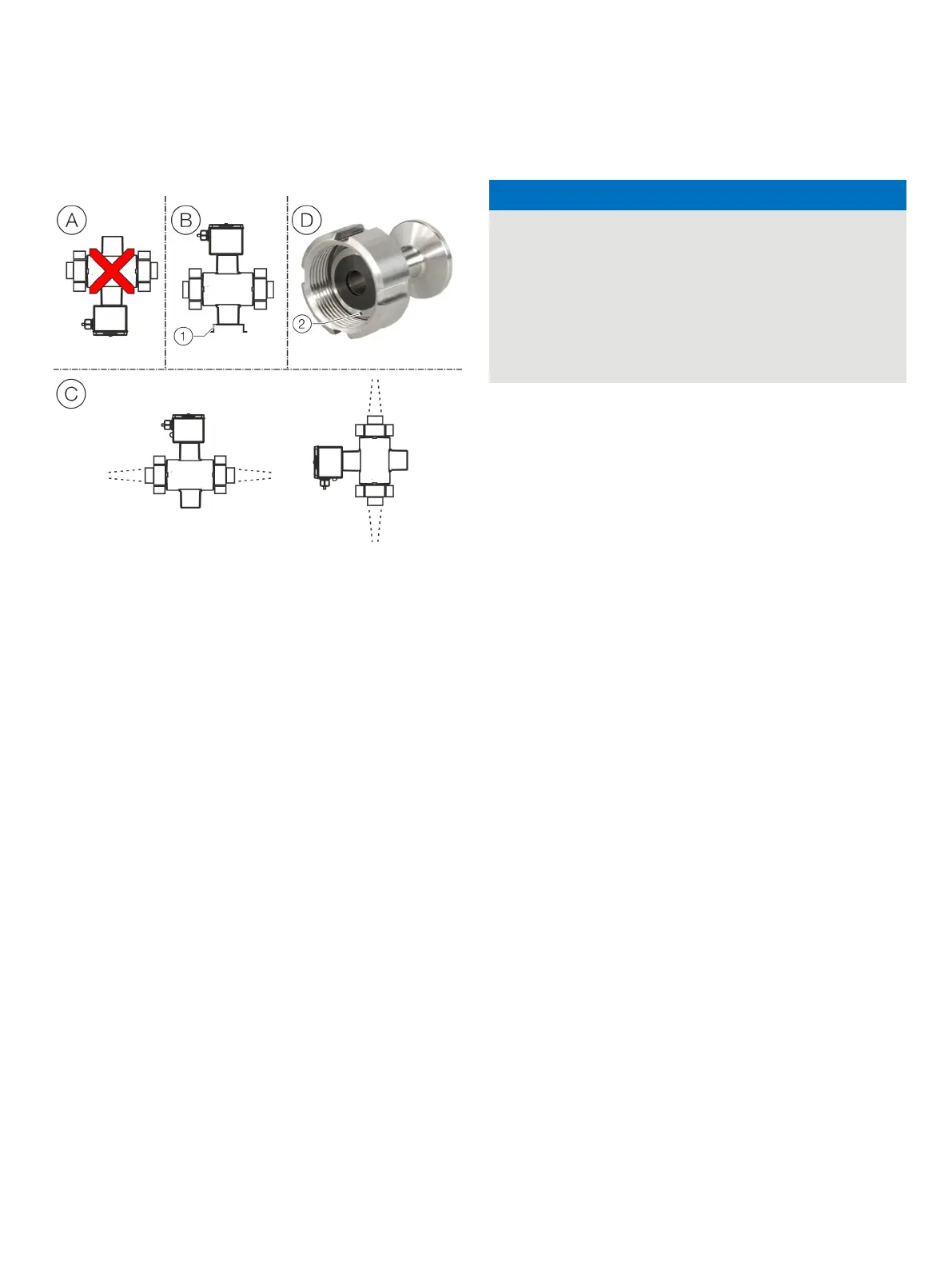

Installation in 3A compliant installations

Angel bracket

Leakage hole

Figure 21: 3A compliant installation

Please observe the following points:

A Do not install the device vertically with the terminal box

or transmitter housing pointing downward.

B The ‘angel bracket’ option is not 3A compliant.

C If concentric reducers are installed on the device, it must

be mounted in a vertical position. See also Installation in

piping with larger nominal diameter on page 18.

D Please make sure that the leakage hole of the process

connection is located at the lowest point of the installed

device.

• A vertical mounting position is preferred. For a horizontal

mounting position, make sure that the sensor is installed

to be self-draining.

• Make sure that the cover of terminal box and / or

transmitter housing is properly sealed. There can be no

gaps between the housing and the cover.

Only devices with the following process connections fulfill 3A

compliance.

• Welded spuds

• Tri-clamp

Installing the sensor

Damage to the device

Damage to the device due to improper assembly.

• The use of graphite with the flange or process connection

gaskets is prohibited. This is because, in some instances,

an electrically conductive coating may form on the inside

of the meter tube.

• Vacuum shocks in the piping should be avoided to prevent

damage to the liners (PTFE liner). Vacuum shocks can

The flowmeter sensor can be installed at any location in the

piping while taking the installation conditions into account.

1. Remove protective plates, if present, to the right and left of

the meter tube. To prevent possible leakage, make sure that

the liner on the flange is not cut or damaged.

2. Position the flowmeter sensor plane parallel and centered

between the piping.

3. Install gaskets between the surfaces, see Gaskets on

page 15.

Note

For achieve the best results, ensure the gaskets fit concentrically

with the meter tube

To guarantee that the flow profile is not distorted, the gaskets

must not protrude into the piping.

Loading...

Loading...