4 Repair

4.6.2. Replacement of motor axis 2

3373HAC022033-001 Revision: K

© Copyright 2004-2011 ABB. All rights reserved.

6.

CAUTION!

The motor weighs 32 kg! All lifting equipment

used must be sized accordingly!

7. Lift the motor and guide it onto the guide pins,

as close to the correct position as possible

without pushing the motor pinion into the

gear.

Make sure that the motor is turned the right

direction, that is the cables facing

downwards.

8. Remove the lifting tool and allow the motor to

rest on the guide pins.

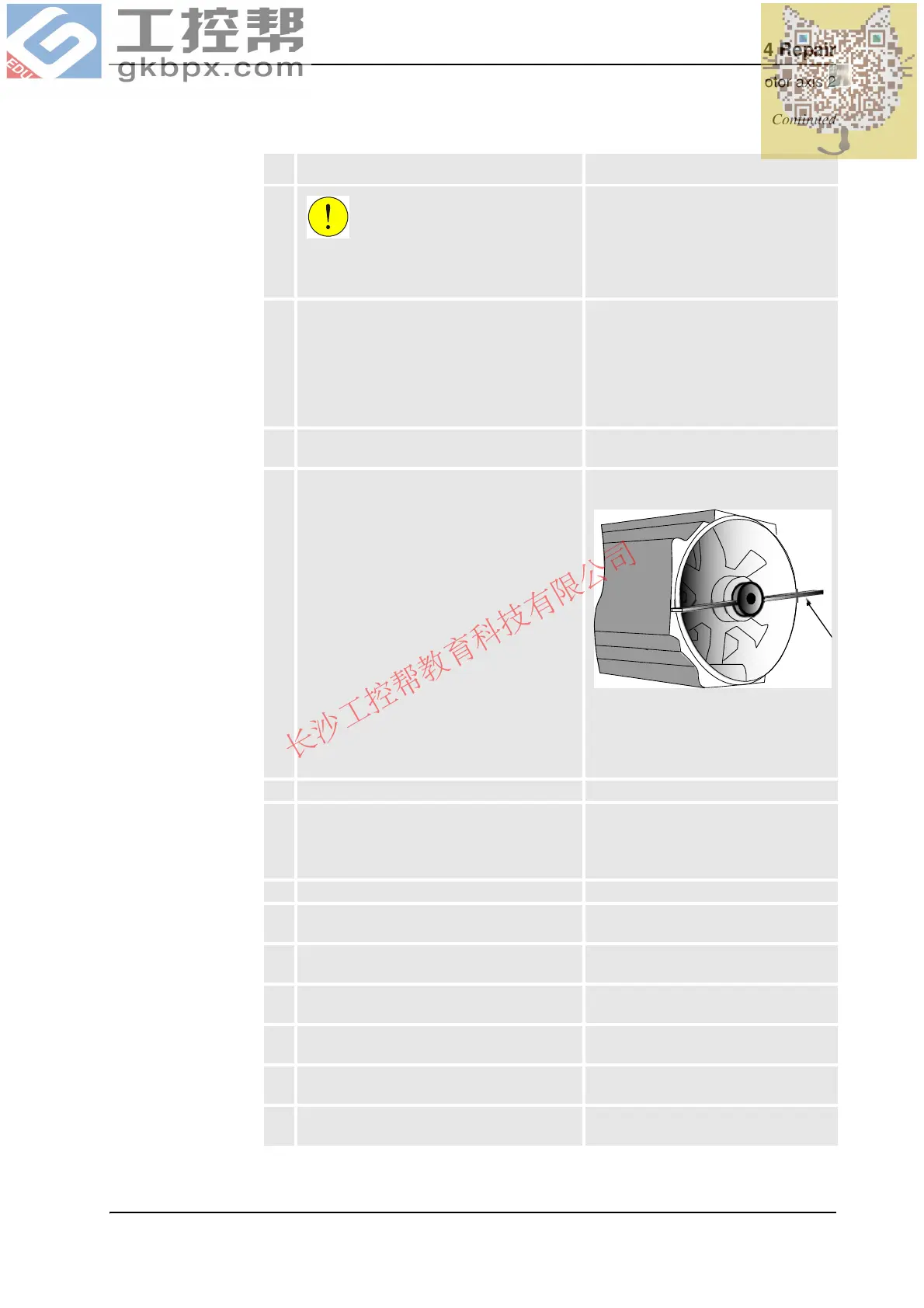

9. Use the rotation tool in order to rotate the

motor pinion when mating it to the gear (see

the figure to the right). Fit the motor, making

sure the motor pinion is properly mated to the

gear of gearbox axis 2 and that it does not get

damaged.

Art. no. is specified in Required

equipment on page 333.

xx0200000165

The rotation tool is used beneath the

motor cover, directly on the motor shaft

as shown in the figure above.

• A: Rotation tool

10. Remove the guide pins.

11. Secure the motor with four attachment screws

and plain washers.

If required, use the extension 300mm for bits

1/2".

M10 x 40, tightening torque: 50 Nm.

Reused screws may be used, providing

they are lubricated as detailed in section

Screw joints on page 423 before fitting.

12. Disconnect the brake release voltage.

13. Reconnect all connectors beneath the motor

cover.

Connect in accordance with markings

on connectors.

14. Refit the cable gland cover at the cable exit

with its two attachment screws.

Shown in the figure Location of motor on

page 333.

15. Refit the cover on top of the motor with its four

attachment screws.

Make sure the cover is tightly sealed!

16. Remove the lock screw from the hole for lock

screw.

Shown in the figure Location of motor on

page 333.

17. Perform a leak down test. Detailed in Performing a leak-down test

on page 246.

18. Refill the gearbox with oil. Detailed in the section Oil change,

gearbox axis 2 on page 203.

Action Note

Continued

Continues on next page

Loading...

Loading...