89

Chapter 7: Troubleshooting

PlateLoc User Guide

Related topics

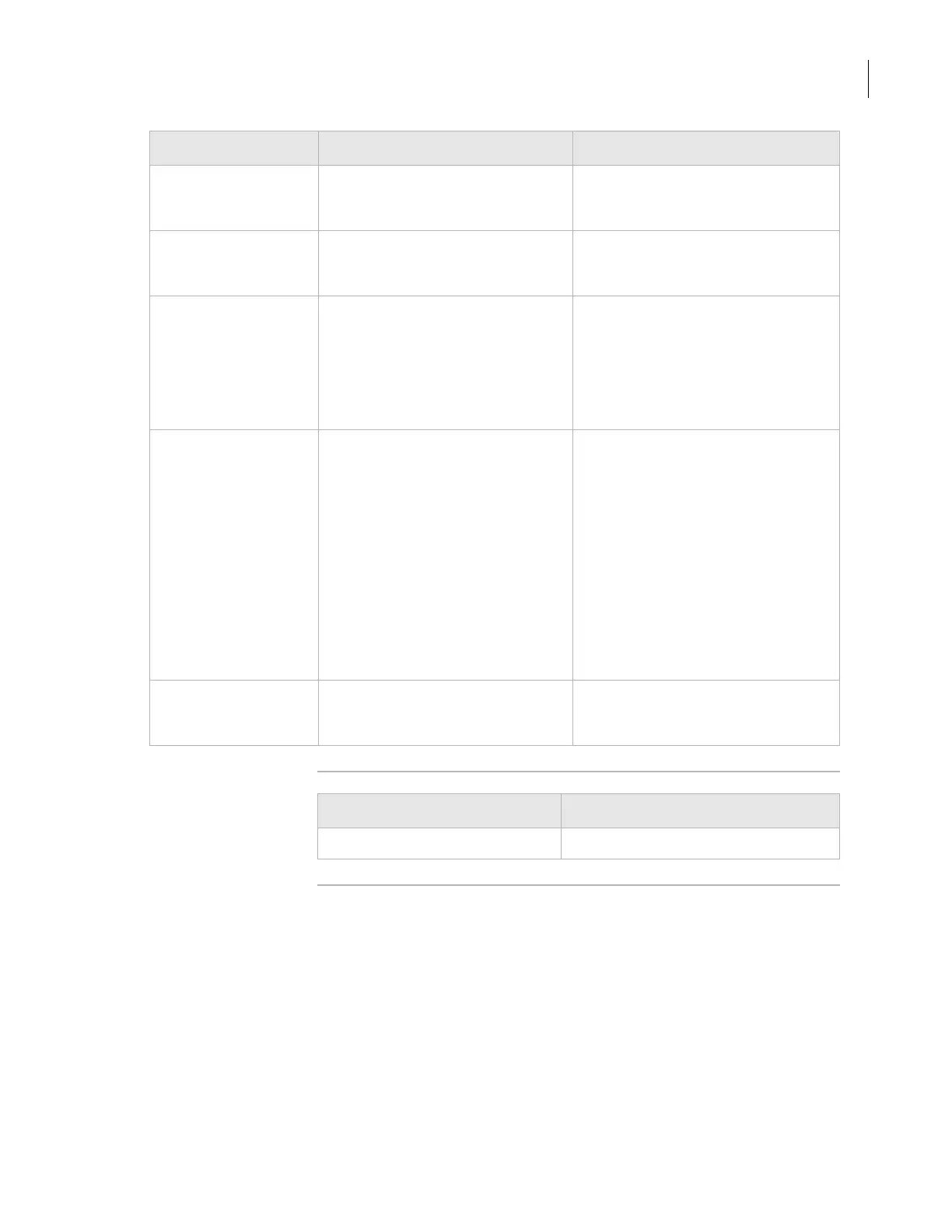

The seal cycle does

not start and an error

message is displayed

The cause of the error is described

on the touch screen.

See “Error messages” on page 90 for

possible solutions.

The seal does not

apply to the plate as

well as it used to.

Excess seal material is stuck to the

heated metal plate (hot plate)

inside the sealing chamber.

Clean the hot plate. For cleaning

instructions, see “Cleaning the hot

plate” on page 84.

The plate is stuck to the

heated metal plate

(hot plate) inside the

sealing chamber or

tends to fall onto the

stage after the seal

cycle.

Excess seal material is stuck to the

heated metal plate (hot plate)

inside the sealing chamber.

Clean the hot plate. For cleaning

instructions, see “Cleaning the hot

plate” on page 84.

The seal cannot be

pulled out from the slot

on the back of the

PlateLoc.

The seal is stuck inside the PlateLoc. 1. Turn off the air and power cycle

the PlateLoc.

2. On the back of the PlateLoc, push

down the red button to open the

seal gripper inside the device.

3. Pull the seal out of the seal-entry

slot.

4. Cut off tattered or folded edges.

5. Re-insert the seal. See “Loading

and unloading a roll of seal” on

page 53 for instructions.

If you are unable to pull the seal out,

contact Velocity11 Technical Support.

Oil is present in the

sealing chamber.

The compressed air is not from an

oil-free compressor and oil has

leaked into the PlateLoc.

Call Velocity11 Technical Support.

Problem Cause Solution

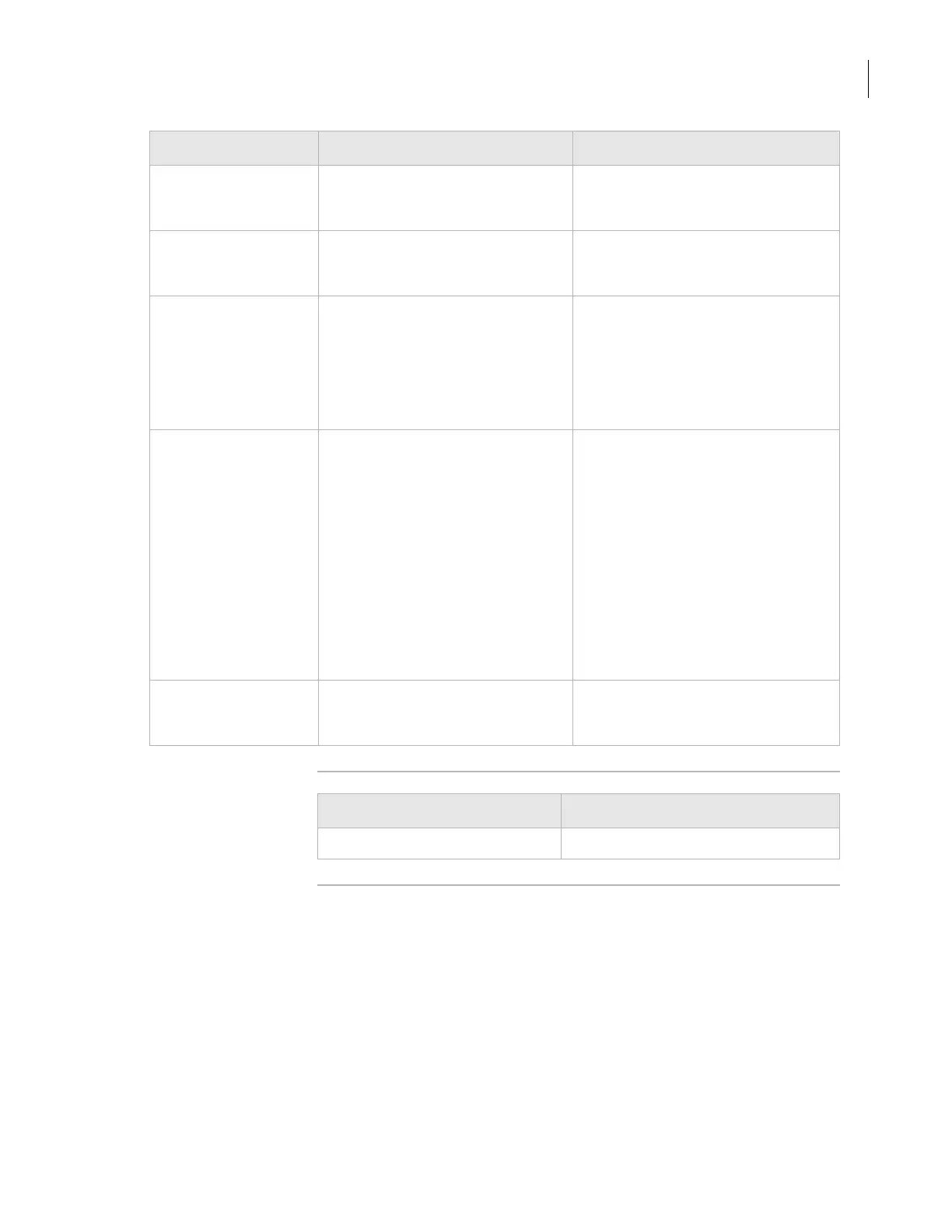

For more information about... See...

Maintaining the PlateLoc “Routine maintenance” on page 83

Loading...

Loading...