Chapter 1: PlateLoc introduction

PlateLoc User Guide

10

Inserts

About this topic This topic describes inserts and their uses in the PlateLoc.

What are inserts Inserts are pads that support the bottoms of plates for uniform seals. You

use inserts to support plates that tend to bend during a seal cycle.

When to use inserts Causes of non-uniform seals

During the seal cycle, a heated metal plate (hot plate) inside the sealing

chamber descends and presses the seal onto the plate. In a quality seal,

the seal material is applied to the plate uniformly. However, the

following factors can cause uneven plate sealing:

❑ Because of the material used, some plates tend to bend in the high-

temperature environment.

❑ In some plate designs, the plate skirt sits higher or lower than the

plate bottom, causing uneven sealing.

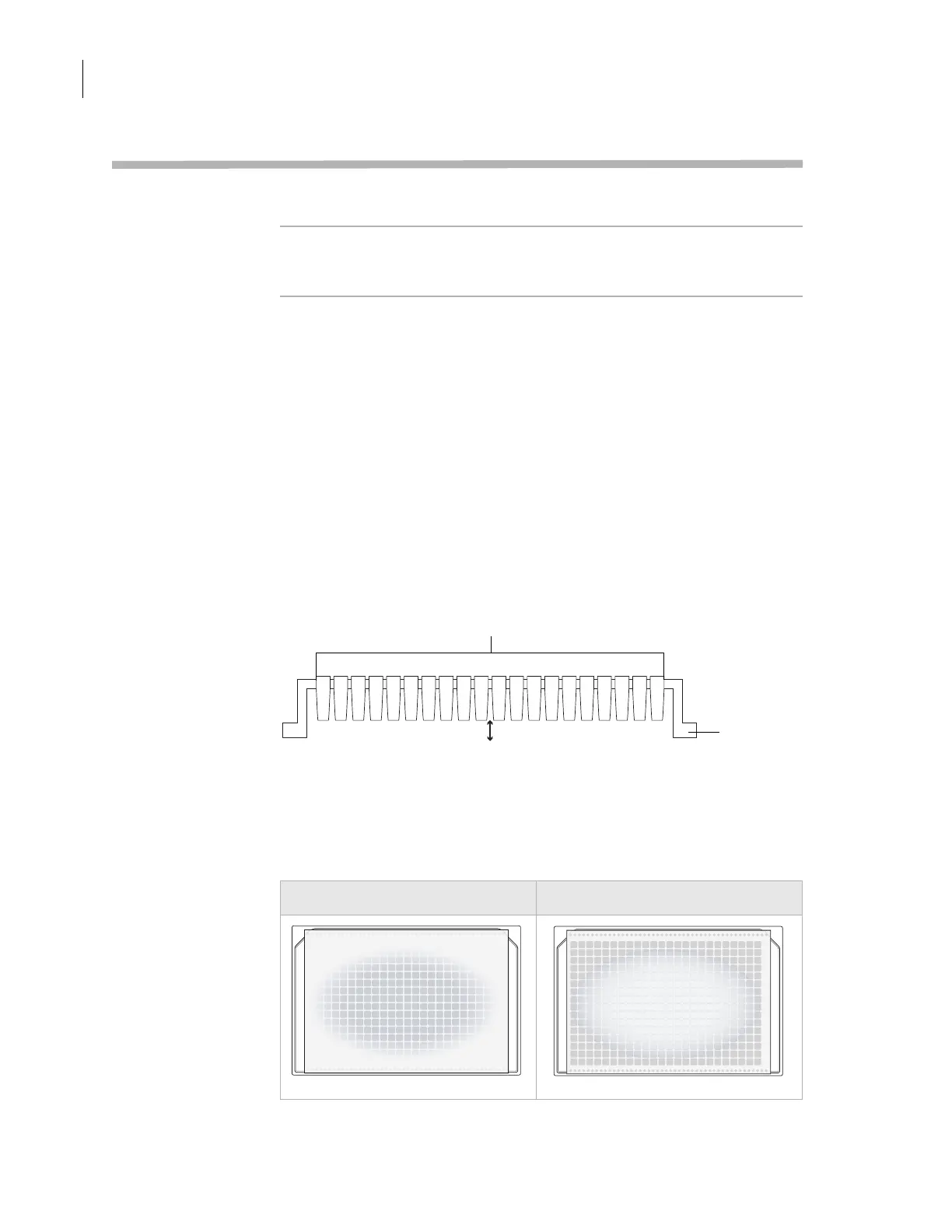

The following diagram shows the side profile of a plate. In this example,

the plate skirt extends past the bottom of the wells. Depending on the

plate material, such plate designs can cause non-uniform sealing. When

the hot plate presses down, the wells at the center of the plate might

bend upward or downward.

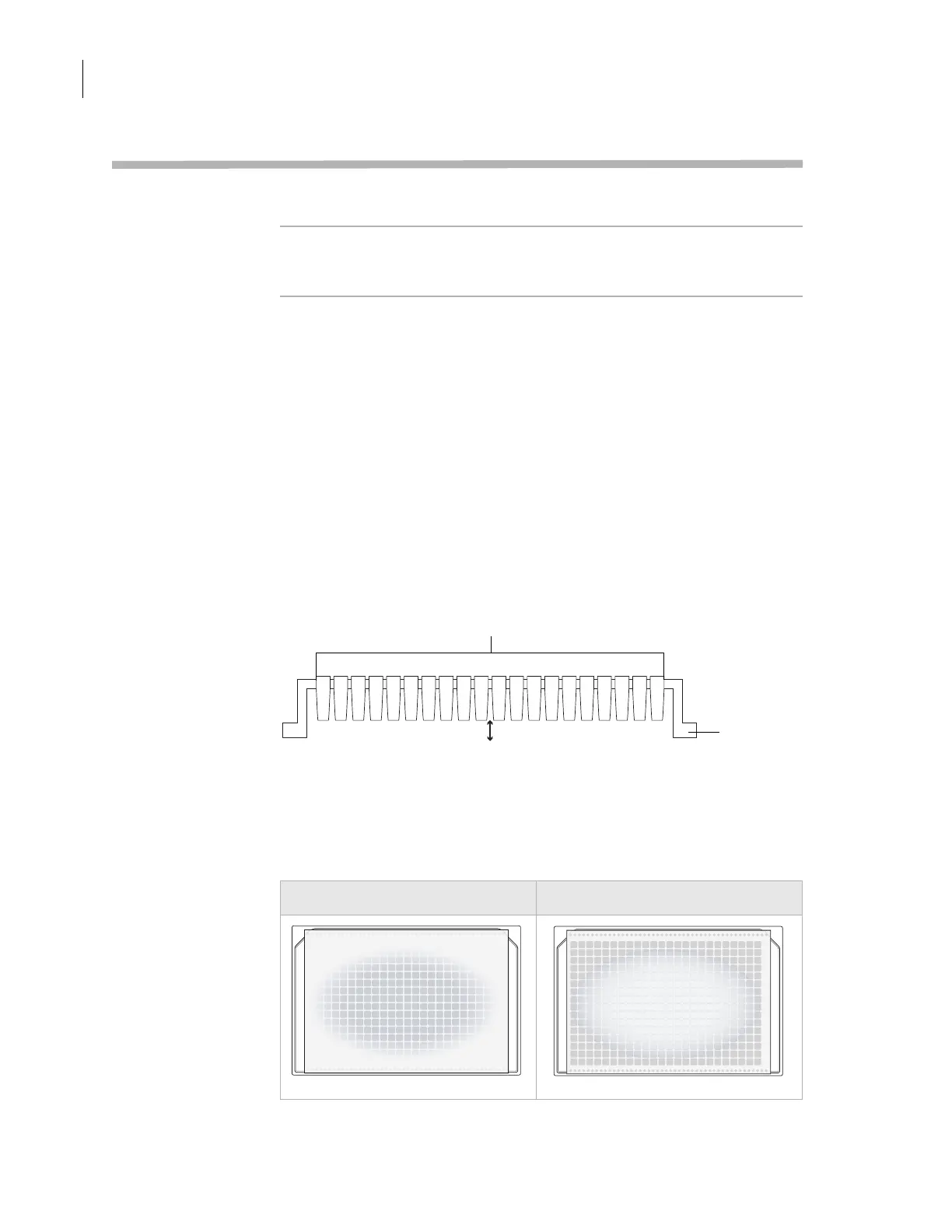

The following diagrams show the top view of sealed plates. Non-uniform

seals can result when the center of the plate bends upward (left) and

downward (right) during the seal cycle.

Skirt

Wells

Bending movement

Plate center is higher Plate center is too low

00200

PlateLoc

shim too high

00200

00199

PlateLoc

shim too low

00199

Loading...

Loading...