11

Chapter 1: PlateLoc introduction

PlateLoc User Guide

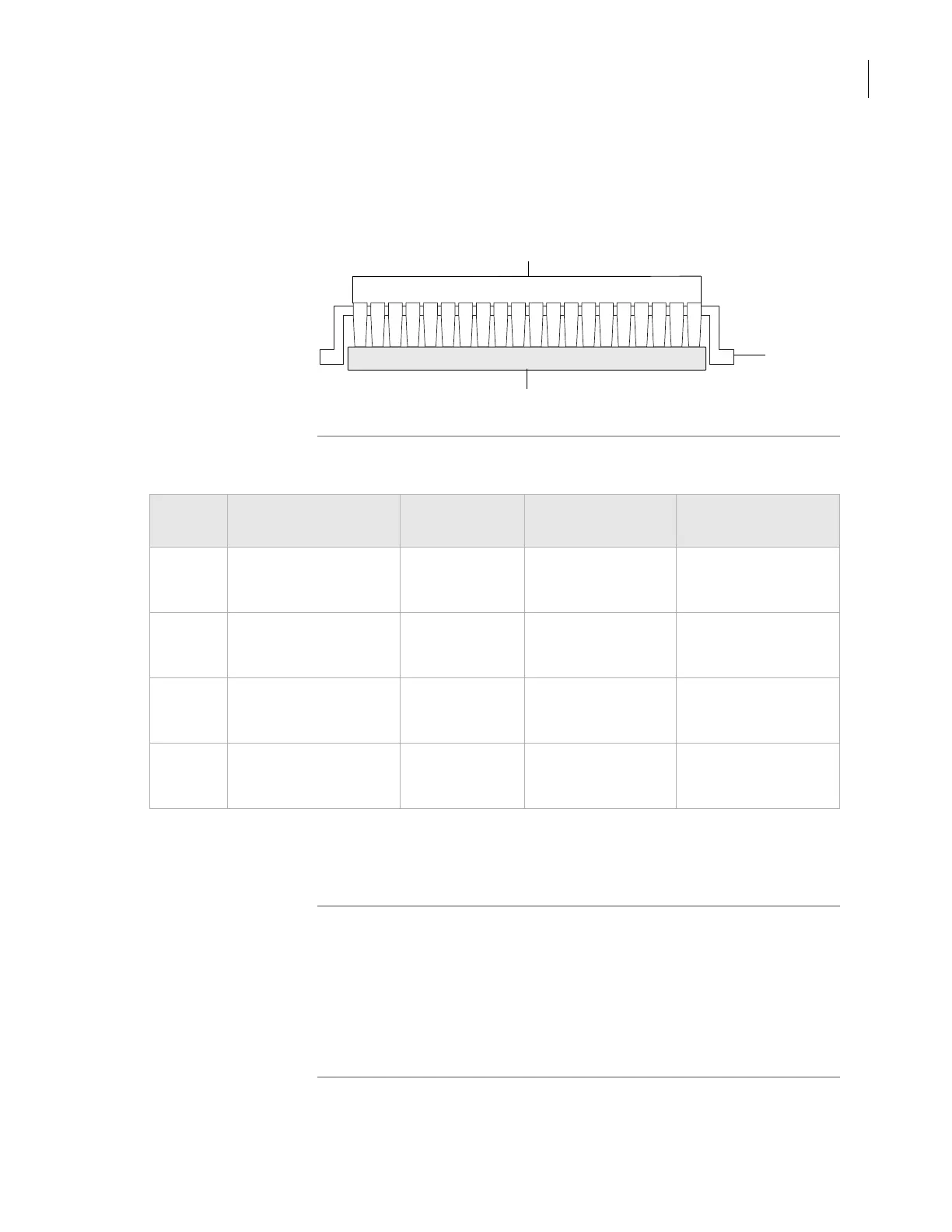

Using inserts to support plates

For plates that tend to bend or do not lie flat during the seal cycle, you

can place an insert under the plate to provide equal support under

every well. The following diagram shows an insert supporting the wells

for uniform sealing.

Inserts supplied with

the PlateLoc

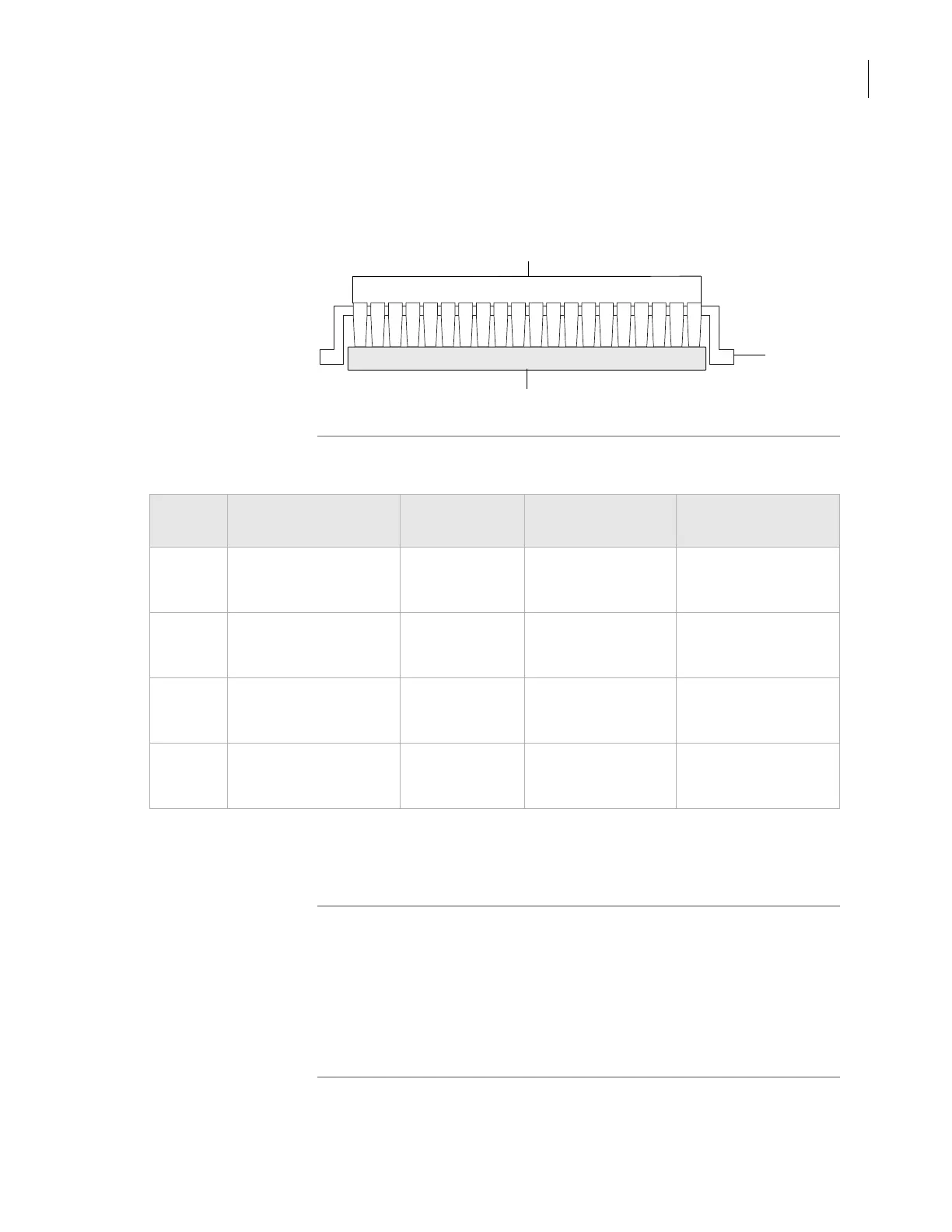

The following table lists the inserts that are supplied with the PlateLoc.

Other types of inserts are available. For a complete list of available

inserts, see the PlateLoc Thermal Plate Sealer Seal Selection Guide. You

can locate the guide on the Velocity11 website at www.velocity11.com.

Insert selection The type of insert you use depends on the plate material and plate

design. Velocity11 recommends that you run optimization tests to

determine the best insert for the plate you are using. See “Optimizing

seal quality” on page 77 for some optimization test guidelines.

For insert selection guidelines and starting parameters to use, see the

PlateLoc Thermal Plate Sealer Seal Selection Guide. You can locate the

guide on the Velocity11 website at www.velocity11.com.

Wells

Skirt

Insert

Insert Description Thickness Height above plate

stage support

Use with...

90 Metal pad with rubber

foam padding on the

plate-facing side

8.65 mm

(0.340 in)

4 mm (0.2 in) Plates that require

flexible support

180 Metal pad 4.60 mm

(0.180 in)

0

mm (0 in)

Plates that require

non-flexible support

under the wells

235 Metal pad 6.00 mm

(0.235 in)

1.4 mm (0.055 in) Plates that require

non-flexible support

under the wells

290 Metal pad 7.37 mm

(0.290 in)

2.8 mm (0.11 in) Plates that require

non-flexible support

under the wells

Loading...

Loading...