Chapter 4: Sealing plates

PlateLoc User Guide

72

Starting the seal cycle

About this topic This topic explains how to seal a plate when using the PlateLoc as a

standalone device or in a Velocity11 lab automation system.

Before you start Make sure:

❑ The PlateLoc is turned on.

❑ The air is turned on and the internal air pressure is 87–90 psi.

❑ Gas-Purging PlateLocs only. The argon source (house or cylinder) is

turned on.

❑ The seal is properly loaded.

❑ Lab automation systems only. Communication between the

controlling computer and the PlateLoc is established.

❑ You have set the correct sealing parameters.

❑ Standalone PlateLoc only. The plate is loaded.

Standalone device

procedure

To start the seal cycle:

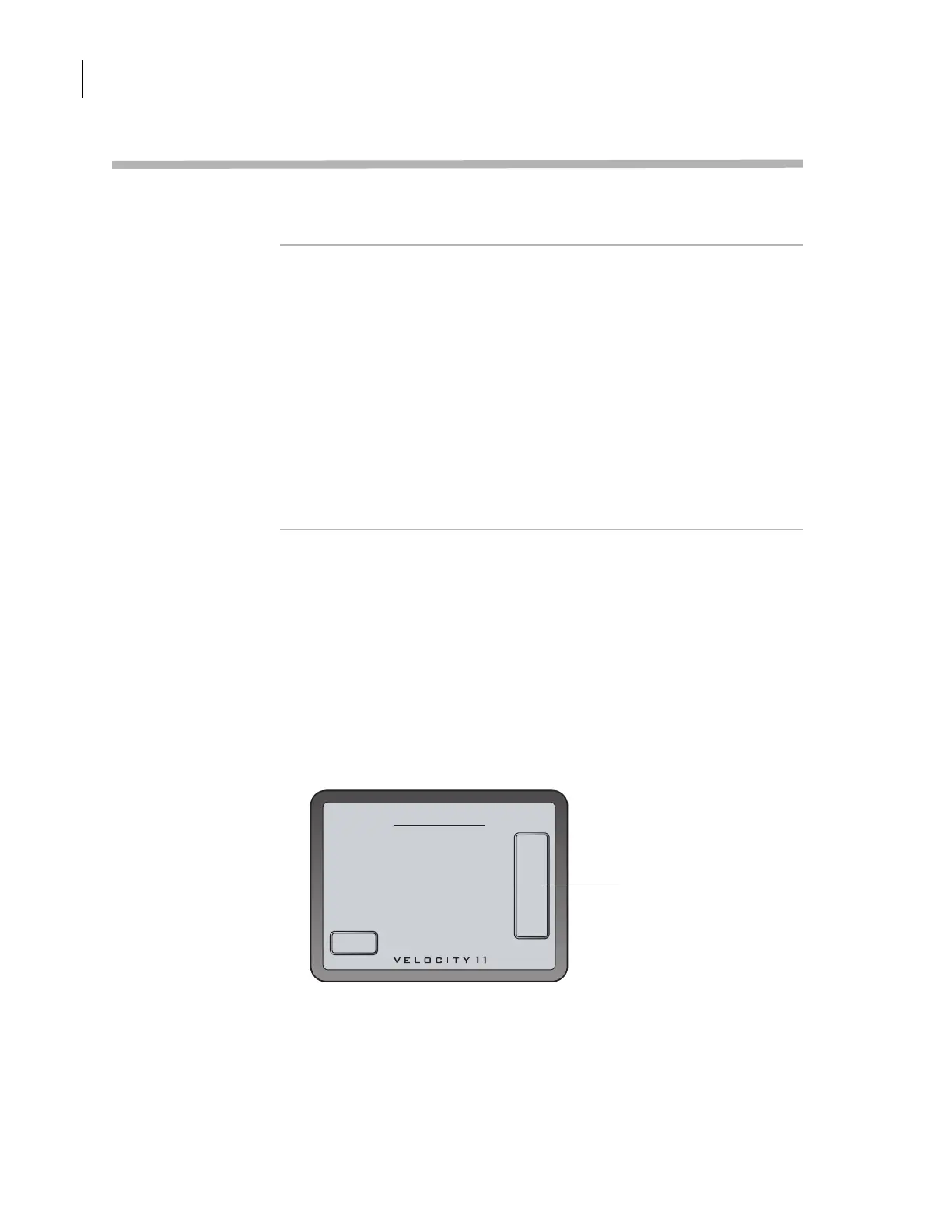

1. From the touch screen

Main Menu, press RUN.

The plate moves into the sealing chamber and the door closes. The

seal cycle begins.

In the Gas-Purging PlateLoc, if the Argon Fill Time is greater than

0.0 seconds, the argon fills the sealing chamber for the specified

amount of time before the seal is applied. The argon automatically

turns off just before the seal is applied.

Note: If the RUN button is blank, the PlateLoc is warming up or

cooling down. You cannot start the seal cycle until the PlateLoc is

within 2 °C of specified sealing temperature.

To monitor the seal cycle progress:

1. On the touch screen

Main Menu, check the Status message.

The following table lists the possible Status messages.

00206

PlateLoc

screen menu 1

Main Menu

Seal Time: 1.8s

Set Time: 1.8 Seconds

Set Temp: 160 Degrees C

Air pressure: 89 psi

Seal Temp: 159°C

Status: Ready

Setup

R

U

N

Press to start the seal cycle.

Loading...

Loading...