Chapter 7: Troubleshooting

PlateLoc User Guide

90

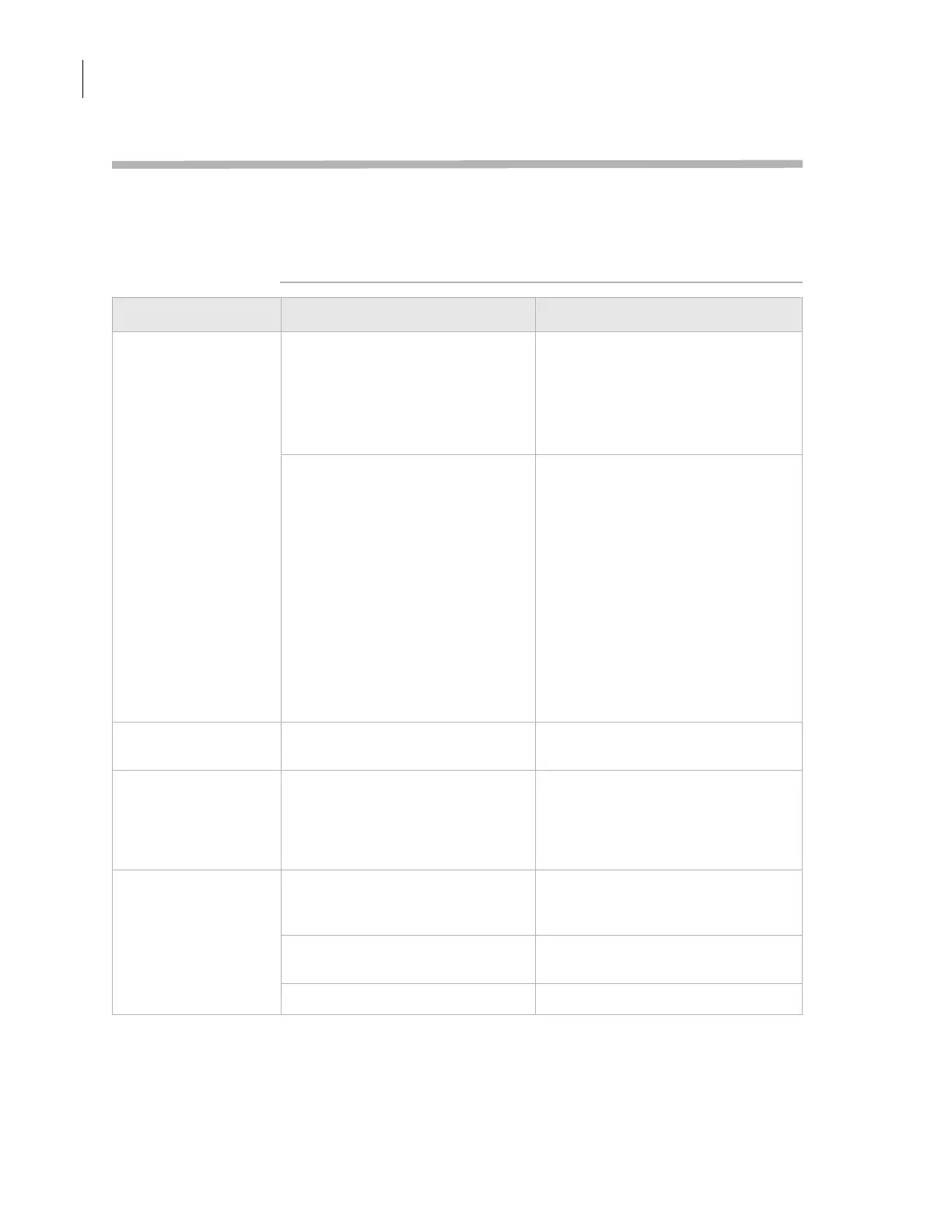

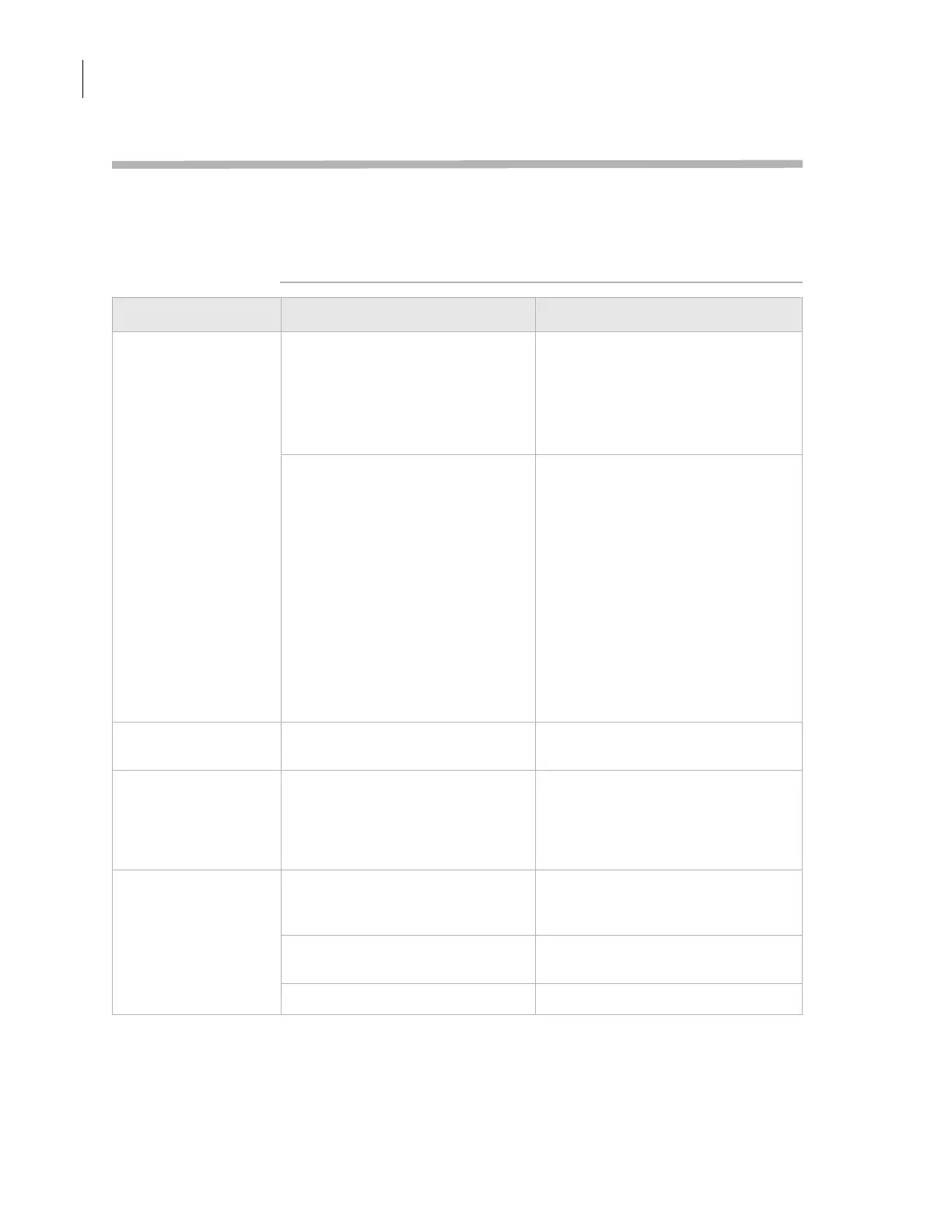

Error messages

About this topic This topic lists possible error messages that are displayed on the touch

screen, the causes of the errors, and ways to resolve the errors. If you are

still experiencing problems with the PlateLoc after trying the solutions,

contact Velocity11 Technical Support.

Error message Cause Solution

Actuator Time Out A sensor or the actuator failed. Make sure the seal material is properly

loaded. Seal a spare plate to make

sure the PlateLoc is working properly

before continuing.

If the error recurs, contact Velocity11

Technical Support.

The air pressure inside the PlateLoc

has dropped below 80 psi.

❑ Make sure the air pressure at the

source (house, cylinder, or

pump) is 0.62–0.69

MPa (90–

100

psi). See “Meeting Lab

requirements” on page 23 for

other requirements.

❑ Check the air connection for

leaks.

❑ In the Gas-Purging PlateLoc,

check that the argon is not

connected to the AIR IN fitting.

If the error recurs, contact Velocity11

Technical Support.

Cutter Not Down The seal-cutting blade inside the

device is out of alignment.

Contact Velocity11 Technical Support.

Cycle Stopped

Manually

The operator pressed STOP to

terminate the seal cycle in progress.

Remove the plate, make sure the seal

is loaded properly, and seal a spare

plate to make sure the PlateLoc is still

working properly. Continue to seal

plates.

Door Close The door was unable to close after

you start the seal cycle or run.

Check for obstacles (for example,

under the door hinge) that are

preventing the door from closing.

The door was opened while the seal

cycle was in progress.

Remove the plate and restart the seal

cycle.

The door sensor is broken. Contact Velocity11 Technical Support.

Loading...

Loading...