91

Chapter 7: Troubleshooting

PlateLoc User Guide

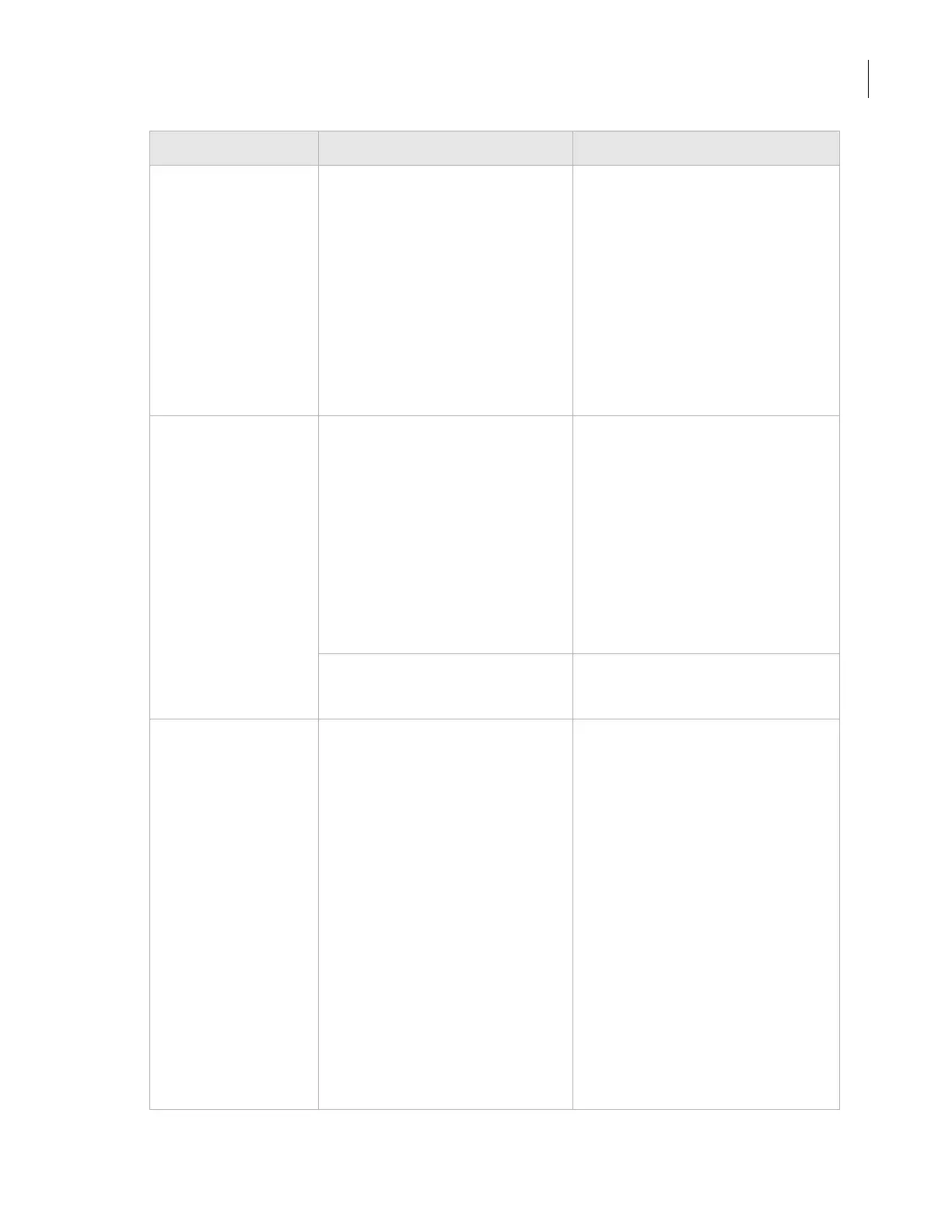

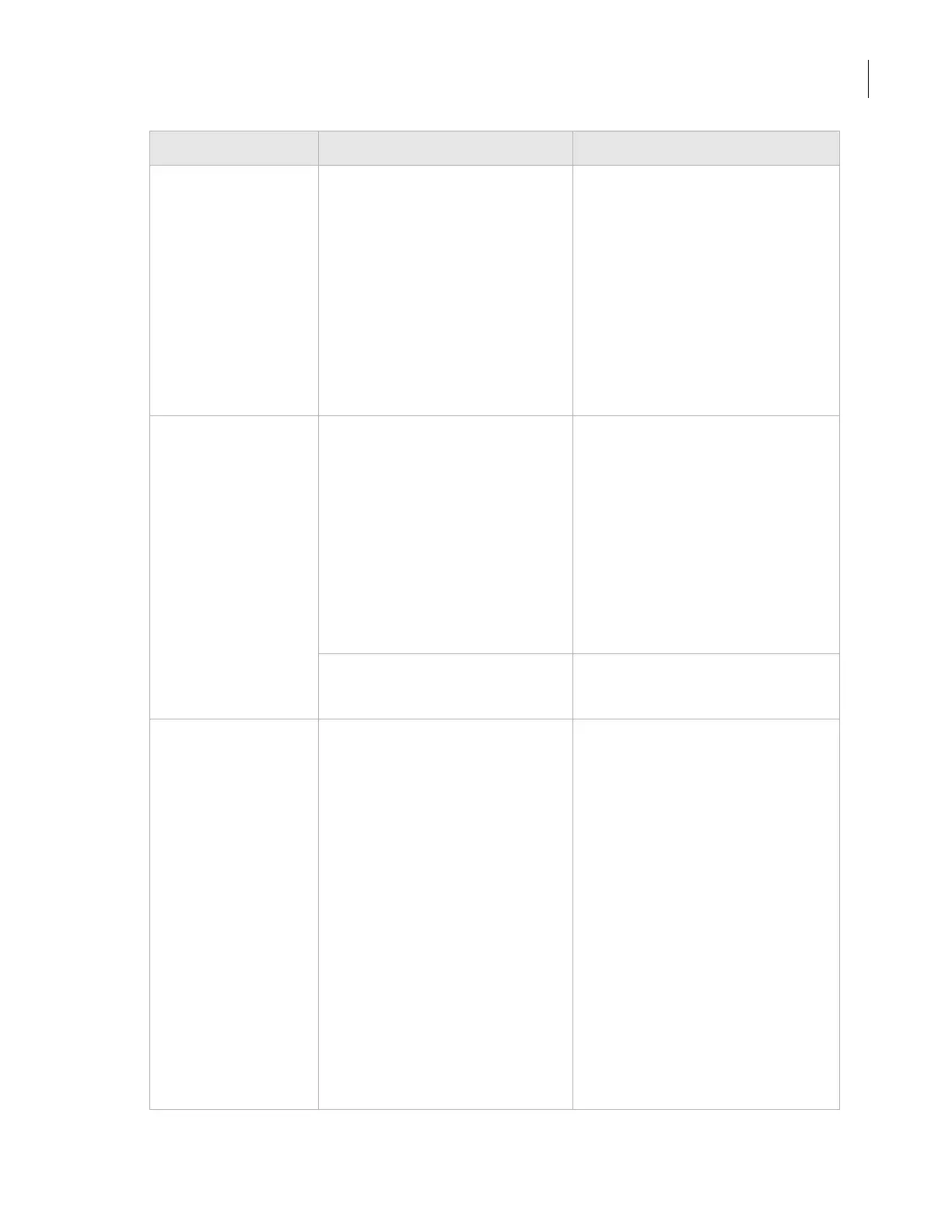

Gripper Plate Vacuum The gripper inside the PlateLoc was

unable to hold the seal material,

and the seal material might be

jammed.

1. Turn off the air and power cycle

the PlateLoc.

2. On the back of the PlateLoc, push

down the red button to open the

seal gripper inside the device.

3. Pull the seal out of the seal-entry

slot.

4. Cut off tattered or folded edges.

5. Re-insert the seal. See “Loading

and unloading a roll of seal” on

page 53 for instructions.

If you are unable to pull the seal out,

contact Velocity11 Technical Support.

Hot Plate Vacuum The hot plate vacuum was unable to

hold the seal material. Small pieces

of seal material might have fallen to

the bottom of the sealing chamber.

❑ Turn off the PlateLoc. Wait for the

PlateLoc to cool down to room

temperature. Open the door and

check for seal material at the

bottom of the sealing chamber.

❑ Seal a spare plate. If the same

error message is displayed, reload

the seal. See “Loading and

unloading a roll of seal” on

page 53.

If the error recurs, contact Velocity11

Technical Support.

Excess seal material is stuck to the

heated metal plate (hot plate)

inside the sealing chamber.

Clean the hot plate. For cleaning

instructions, see “Cleaning the hot

plate” on page 84.

Insufficient Air

Pressure

The air pressure inside the PlateLoc

is below 80 psi.

❑ Make sure the air pressure at the

source (house, cylinder, or

pump) is 0.62–0.69

MPa (90–

100

psi). See “Meeting Lab

requirements” on page 23 for

other requirements.

❑ If the air pressure at the source is

sufficient, but the air pressure

inside the PlateLoc is still too low

(as shown on the touch screen),

check the air connection for

leaks.

❑ In the Gas-Purging PlateLocs,

check that the argon is not

connected to the AIR IN fitting.

❑ If the air pressure and

connections are correct, but the

air pressure inside the PlateLoc is

still too low, contact Velocity11

Technical Support.

Error message Cause Solution

Loading...

Loading...