45

Chapter 3: Getting started

PlateLoc User Guide

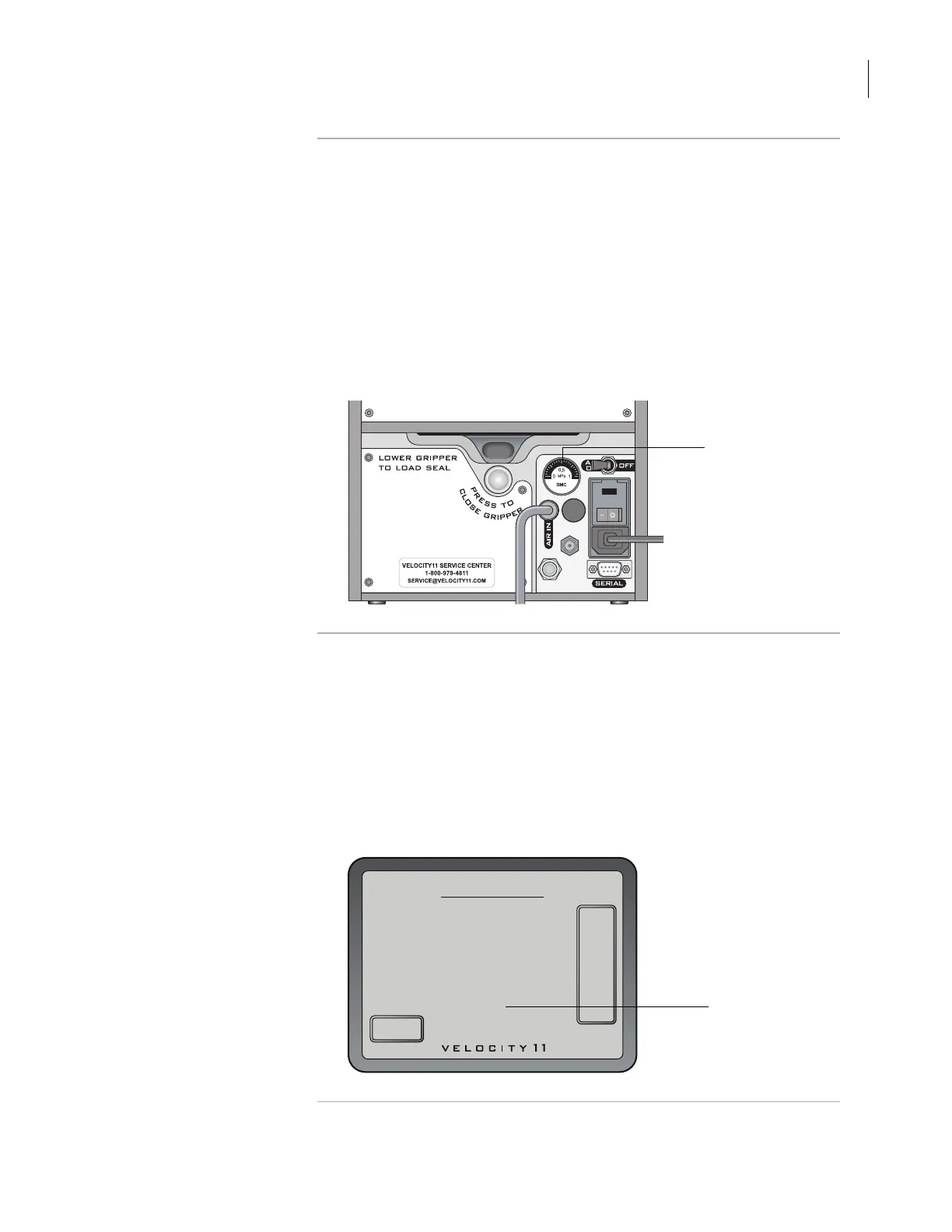

Checking for air flow To check that air is flowing into the PlateLoc:

1. Check the pressure gauge on the back of the PlateLoc.

If air is flowing into the device, the gauge should show a non-zero

pressure value.

If the gauge shows 0 psi, check the air tubing connections and the

connections at the source (house, cylinder, or pump).

!! IMPORTANT !!

The pressure reading on the back of the

PlateLoc might be different from the value shown on the

touch screen. The pressure gauge on the back of the PlateLoc

should be used to determine the presence of air flow only. To

check the air pressure inside of the device, view the air

pressure information displayed on the touch screen.

Checking the

internal air pressure

Although the required air pressure from your lab is 0.62–0.69 MPa

(90–100 psi), the PlateLoc down-regulates the pressure inside the

device. For optimum results, the air pressure should be approximately

87–90 psi inside the sealing chamber.

To check the internal air pressure:

1. Check the touch screen

Main Menu. The air pressure is displayed

below the Status and should be 87–90 psi.

The following diagram shows the Main Menu and the location of the

air pressure information.

00191

PlateLoc

connections

00191

PlateLoc

connections

Check the gauge

for air flow.

00206

PlateLoc

screen menu 1

Main Menu

Seal Time: 1.8s

Set Time: 1.8 Seconds

Set Temp: 20 Degrees C

Air pressure: 89 psi

Seal Temp: 20°C

Status: Ready

Setup

R

U

N

Check the internal

air pressure.

Loading...

Loading...