111

Appendix A: Integrating the PlateLoc into third-party systems

PlateLoc User Guide

GetFirmwareVersion Description

Commands the application to get the PlateLoc's firmware version

number.

Parameters

None

Returns

BSTR

Visual C++ Example

str = m_PlateLoc.GetFirmwareVersion();

Visual Basic Example

str = PlateLoc1.GetFirmwareVersion

GetCycleCount Description

Commands the application to get the number of seal cycles that have

been performed.

Parameters

Returns

LONG

Visual C++ Example

LONG cycle_count;

lres = m_PlateLoc.GetCycleCount(&cycle_count);

Visual Basic Example

DIM cycle_count as INTEGER

lres = PlateLoc1.GetCycleCount cycle_count

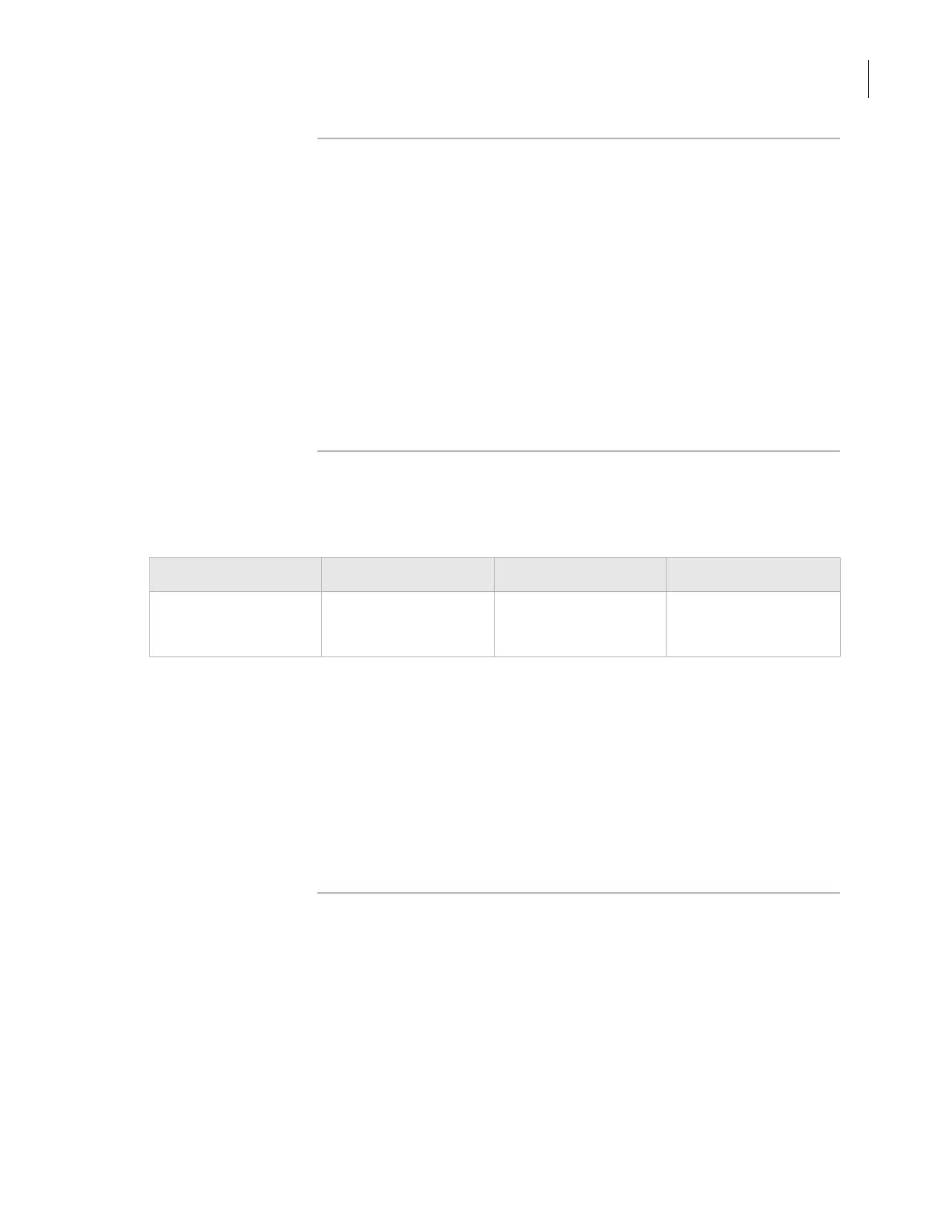

Name Type Range Description

cycle_count LONG * 0 Stores the number of

seal cycles after

returning from the call