28 Rockwell Automation Publication 6000-UM002E-EN-P - April 2018

Chapter 2 Drive System Layout

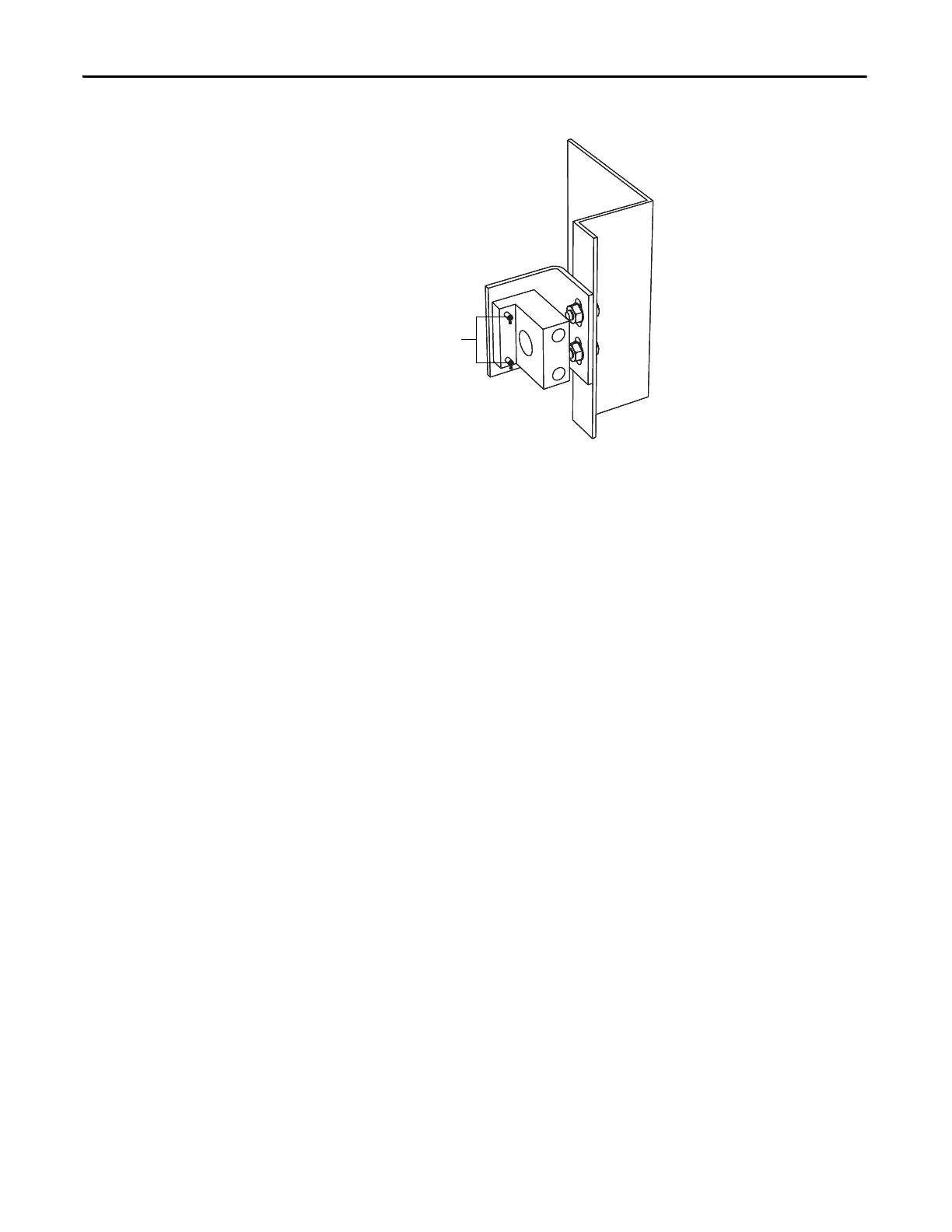

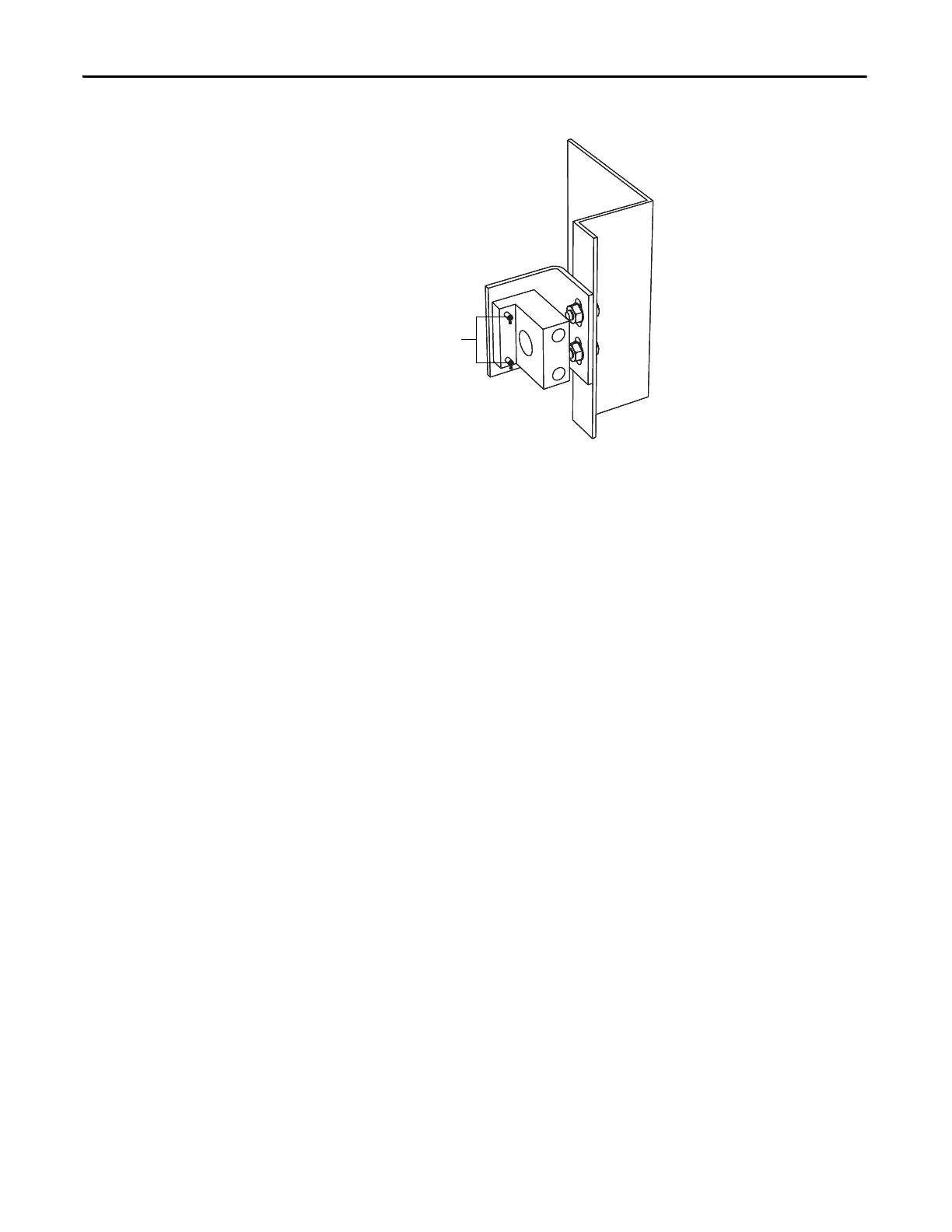

Figure 18 - Dead Bolt Counterpart Mounted to Cabinet

4. Bolt the cabinet door closed so the pins on the dead bolt counterpart make

contact with the dead bolt assembly. Doing so should leave two marks of

torque sealant or grease on the assembly where the pins made contact (See

Figure 13).

5. Slightly loosen the adjustment bolts on the counterpart and make the

necessary movements on the counterpart to ensure that the pins align with

the landing plates on the dead bolt assembly. As the amount of counterpart

movement required is an estimate, it may take a couple attempts to

properly align the assembly.

6. Clean the torque seal/grease from the key interlock once finished aligning

the counterpart.

Once properly aligned, the key should turn freely when the cabinet door is fully

bolted shut. If the key does not function when the door is tightly bolted closed,

adjustments will have to be made to the depth of the counterpart. This can be

done by adding shims on the landing plate where the counterpart is mounted.

Besides the mechanical interlock, PowerFlex 6000 drives also provide

Guardmaster® safety limit switch on each cabinet door that interlocks with input

switching devices.

When any of the cabinet doors are open, the drive will turn off the IGBT output.

At the same time, a trip signal will be sent to the circuit breaker to open the

circuit.

Two pairs of passive dry contacts (open and close) are provided to the user.

Place grease on

dead bolt pins here

Loading...

Loading...