Rockwell Automation Publication 6000-UM002E-EN-P - April 2018 37

Drive System Layout Chapter 2

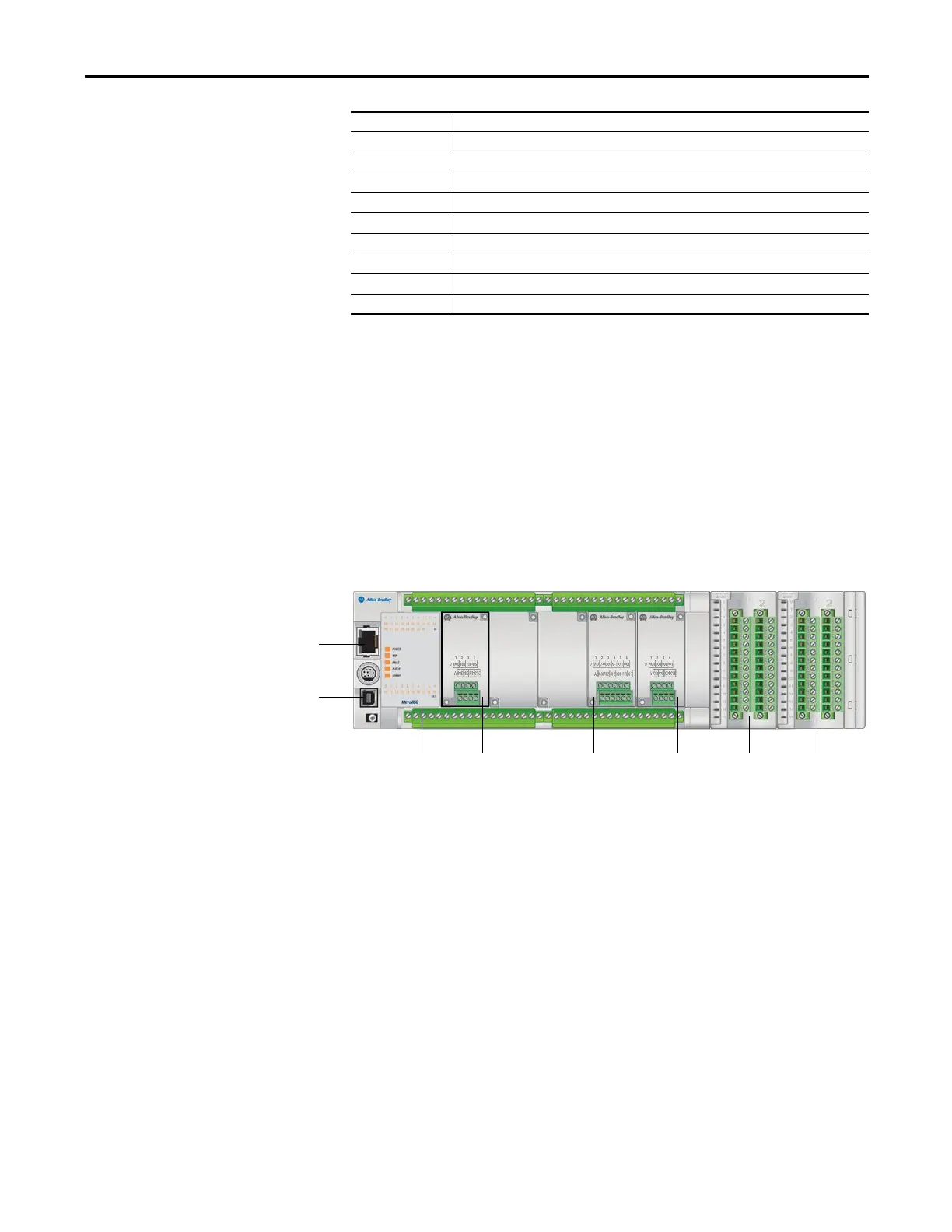

PLC

The PowerFlex 6000 uses a Micro850 PLC to perform many of its internal

control functions. The PLC controls and monitors the cooling fans, input and

bypass switching devices, door switch status, etc. The PLC is also responsible for

interfacing with the user's automation control system via many optional

communication protocols. Standard communication protocols are EtherNet/IP,

Modbus/TCP Server and Modbus RTU. Optional communication modules are

available to support other communication protocols.

Figure 27 - PLC Overview

HMI

The PowerFlex 6000 HMI is a PanelView™ Plus 6 series, catalog number 2711P-

T7C4D9.

The HMI is connected to the controller (Micro850) through a communication

interface (standard RJ45 EtherNet/IP connection). The HMI configures

operating parameters and input operation commands, and displays the operation

status, operation parameters, parameter trends, and fault messages.

5V 5V power supply indicator

3.3V 3.3V power supply indicator

Digital Signal Processor Board Indicator Lights

HVEN Allow High voltage switching on indicator

RUN Drive Running indicator

Fault Drive is in fault state

Trip Drive is in trip state; any fault can result in trip

Standby –

Standby –

Standby –

Power input

Extend I/O Extend I/OPlug inPLC Plug in Plug in

EtherNet/IP port

Loading...

Loading...