36 Rockwell Automation Publication 6000-UM002E-EN-P - April 2018

Chapter 2 Drive System Layout

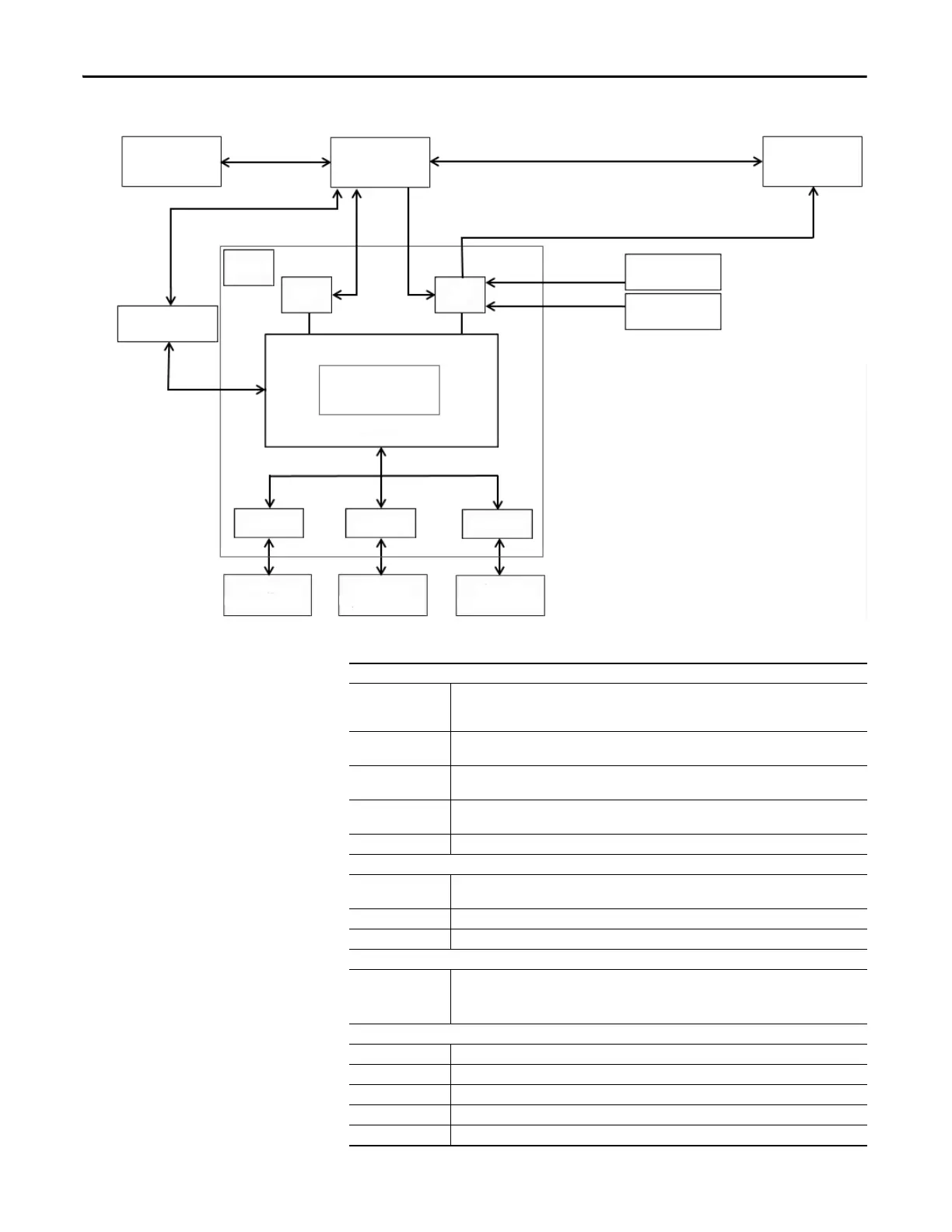

Figure 26 - Control Unit Layout

Table 3 - Control Unit Description

HMI

PWM Board A

DCS

Phase A

Power Modules

Fieldbus

VSB

HECS

PLC

Communication

Board

PWM Board B PWM Board C

Phase C

Power Modules

DT

AT

DB

CPU Board

Phase B

Power Modules

RJ45 Modbus TCP/IP

RS-232

Modbus RTU

Fiber Optic

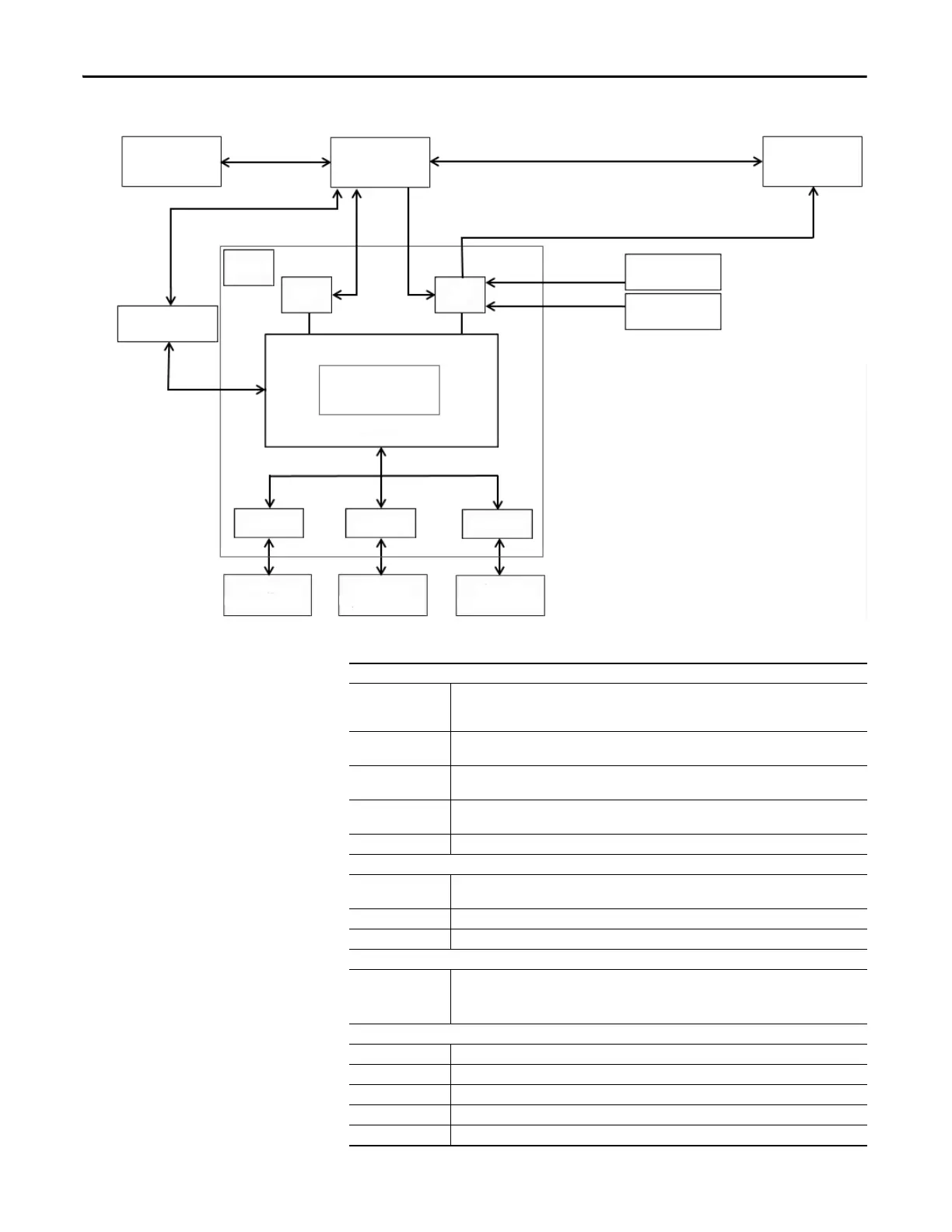

Board Function

PWM Board A, B, C Output PWM and control signals to Power Modules

Collect and process fault and state information from Power Modules to CPU board

Each phase PWM board can control up to nine power cells

CPU Board Process analog input signals, switch and fault information, control DA and switch signal output,

realize V/F algorithm, set and change parameters in communication with PLC

Analog Signal

Processor Board (AT)

Collect and process analog input signals to CPU Board, output analog signals processed by DT

board

Digital Signal

Processor Board (DT)

Collect and output digital signals, digital to analog conversion function

DB Board Acts as a base board in the Control Unit and interfaces the digital and analog signal cables

Connector

PLC Communication

Interface

Connection between PLC and Control Unit.

Fiber Optic Socket Connection between Power Modules and Control Unit (two per module)

Interface Terminals Connects external inputs and outputs

Status Indicators

Phase control board

transceiver indicator

light

B: board healthy indicator

T: transmit data to power module indicator

R: receive data from power module indicator

CPU Board Indicator Lights

RX Receive communication signals from PLC

TX Transmit communication signals to PLC

FPGA FPGA healthy indicator

DSP2 DSP2 healthy indicator

DSP1 DSP1 healthy indicator

Loading...

Loading...