Copyright © 1996 General Motors Corp. 7–13

ASSEMBLY OF TRANSMISSION

NOTE:

• For models with retarder, proceed with Step (8).

• For models without retarder, skip Step (8) and

proceed with Step (9).

(8) For models with retarder, install six M6-1

bolts 39 (Foldout 7,B). Tighten bolts 39 to 9–10 lb ft

(12–14 N

.

m).

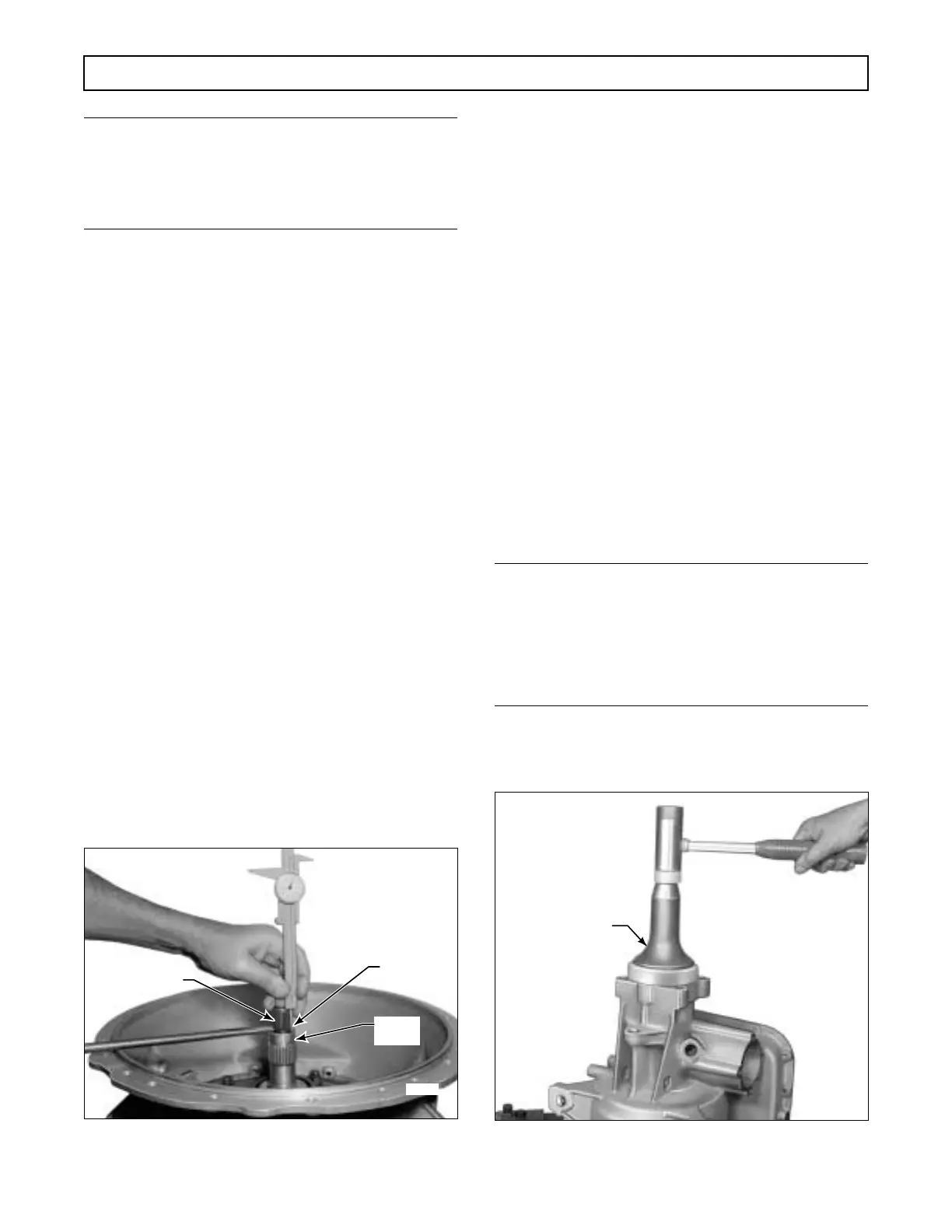

(9) To check the turbine shaft end play,

mount a vernier dial caliper on the turbine shaft. Raise

the shaft, extending the depth gauge to bear upon the

stator shaft and record the dial reading (Figure 7–30).

(10) Release the shaft and record the dial read-

ing. If the dial reading does not fall within the desired

end play range of 0.005–0.034 inch (0.13–0.85 mm),

the thickness of the selective thrust washer must be re-

calculated.

(11) Remove the compressor base, J 23630-2,

installed in Paragraph 7–6a, from the transmission

housing and output shaft.

7–9. INSTALLATION OF OUTPUT

SHAFT OIL SEAL

(Foldout 12,B)

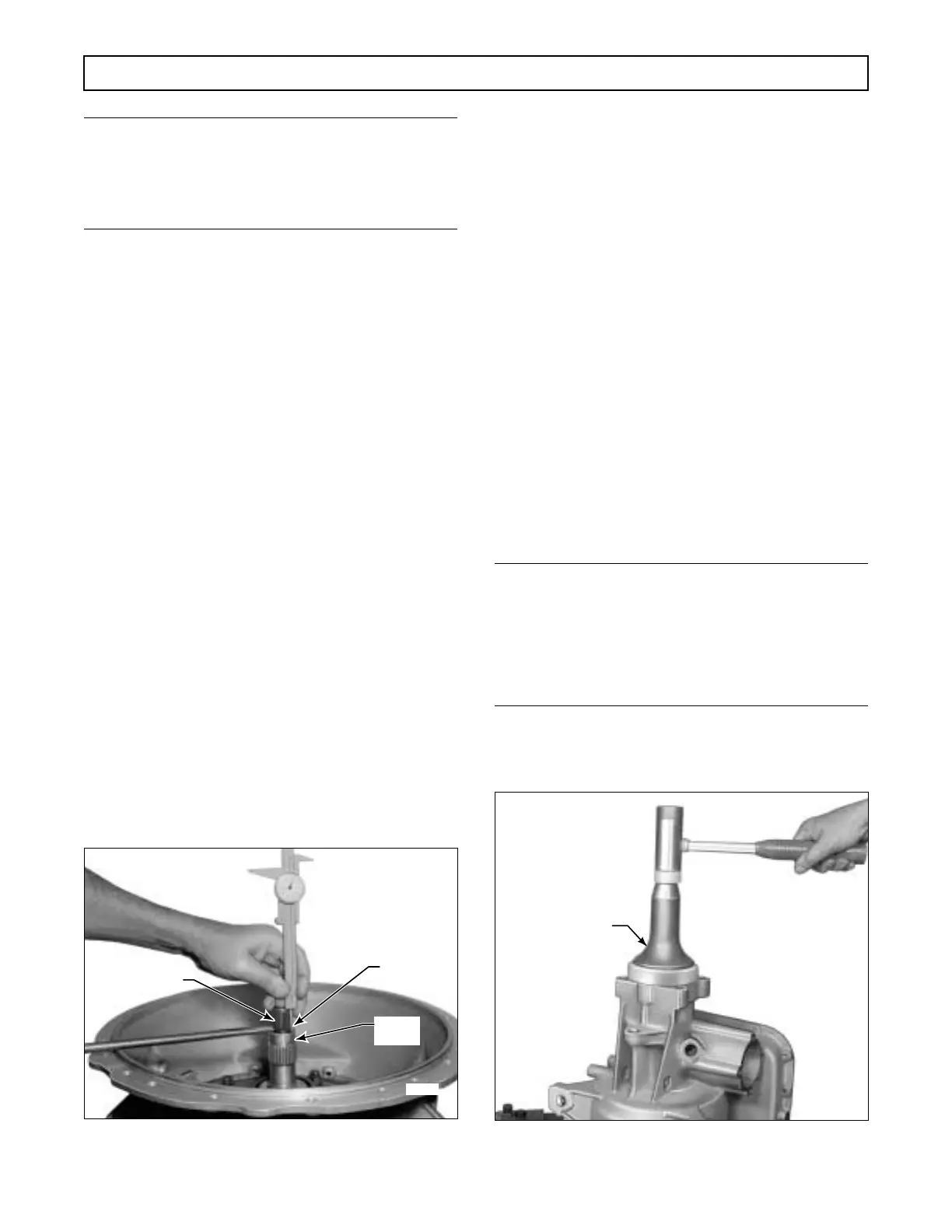

(1) Refer to Paragraph 4–6e. Coat the lip of

oil seal 6 with high temperature grease.

Figure 7–30. Measuring Turbine Shaft End Play

(2) Start the oil seal, lip first, squarely into

the rear bore of the transmission housing.

(3) Using installer tool J 23631, drive the oil

seal into the housing until the installer seats against the

housing (Figure 7–31). The rear of the oil seal will be

0.51–0.55 inch (13.0–14.0 mm) forward of the brake

mounting surface of the transmission housing when

properly installed.

(4) Refer to Paragraph 3–16h for the instal-

lation of the output flange and retaining bolt and

washer.

7–10. INSTALLATION OF MAIN

CONTROL VALVE BODY, OIL

FILTER, AND OIL PAN

a. Main Control Valve Body

NOTE:

If the control valve body assembly was replaced, it

will perform properly only if it is functionally com-

patible with the main housing channeling. Refer to

Parts Catalog SA1235 for part numbers and serial

number application.

(1) Position the transmission housing bottom

side upward.

Figure 7–31. Installing Output Shaft Oil Seal

H02997

STATOR

SHAFT

DEPTH

GAUGE

TURBINE SHAFT

Loading...

Loading...