PAGE 54

Section 10 - TSection 10 - T

Section 10 - TSection 10 - T

Section 10 - T

roubleshootingroubleshooting

roubleshootingroubleshooting

roubleshooting

10.1 K10.1 K

10.1 K10.1 K

10.1 K

eeping the Teeping the T

eeping the Teeping the T

eeping the T

ransmitter Calibratedransmitter Calibrated

ransmitter Calibratedransmitter Calibrated

ransmitter Calibrated

Depending on application circumstances, periodically calibrate the transmitter to maintain

measurement accuracy.

Maintenance Tip! Upon startup, frequently check the system until operating

experience can determine the optimum time between calibrations that provides

acceptable measurement results.

Calibrate the transmitter using a method described in Section 8.3, 8.4 or 8.5. Calibrating with

old, contaminated or diluted reference solution may cause measure-ment errors. Do not reuse

reference solutions. Note that the value of a reference solution changes as its temperature

changes. Therefore, always allow the temperatures of the sensor and reference solution to

equalize while calibrating.

10.2 Avoiding Electrical Interference10.2 Avoiding Electrical Interference

10.2 Avoiding Electrical Interference10.2 Avoiding Electrical Interference

10.2 Avoiding Electrical Interference

Recommendation: Do not run sensor cable (and interconnect cable, if used) in

same conduit with AC or DC power.

Maintenance Tip! Excess cable should not be coiled near motors or other

equipment that may generate electrical or magnetic fields. Cut cables to proper

length during installation to avoid unnecessary inductive pickup (“electrical noise”

may interfere with the sensor signal).

When experiencing problems, try to determine the primary measurement system component

causing the problem (sensor, transmitter or interconnect cable, if used).

10.3 Checking Electrical Connections10.3 Checking Electrical Connections

10.3 Checking Electrical Connections10.3 Checking Electrical Connections

10.3 Checking Electrical Connections

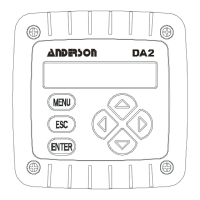

1. Verify that adequate DC voltage exists at the appropriate transmitter TB1 terminals.

2. Check all transmitter wiring to ensure proper connections.

10.4 V10.4 V

10.4 V10.4 V

10.4 V

erifying Sensor Operationerifying Sensor Operation

erifying Sensor Operationerifying Sensor Operation

erifying Sensor Operation

To verify sensor operation, refer to the procedure in the troubleshooting section of the sensor

operating manual. Or replace the suspect sensor with a known new or working sensor and

perform calibration.

10.5 V10.5 V

10.5 V10.5 V

10.5 V

erifying Terifying T

erifying Terifying T

erifying T

ransmitter Operationransmitter Operation

ransmitter Operationransmitter Operation

ransmitter Operation

1. After disconnecting DC power and the sensor from the transmitter, connect a 1000 ohm

resistor between Terminals 4 (red) and 5 (yellow) on TB2.

2. Connect a 100,000 ohm resistor between Terminals 1 (white) and 7 (green) on TB2.

3. Reconnect DC power to the transmitter.

4. Verify that the transmitter conductivity reading is between 5.00 and 50.00 mS/cm. Also,

verify that the temperature reading is between -10 and +10°C.

If these readings are achieved, the transmitter is operating properly, but the interconnect cable

(if used) may be faulty.

Loading...

Loading...