PAGE 45

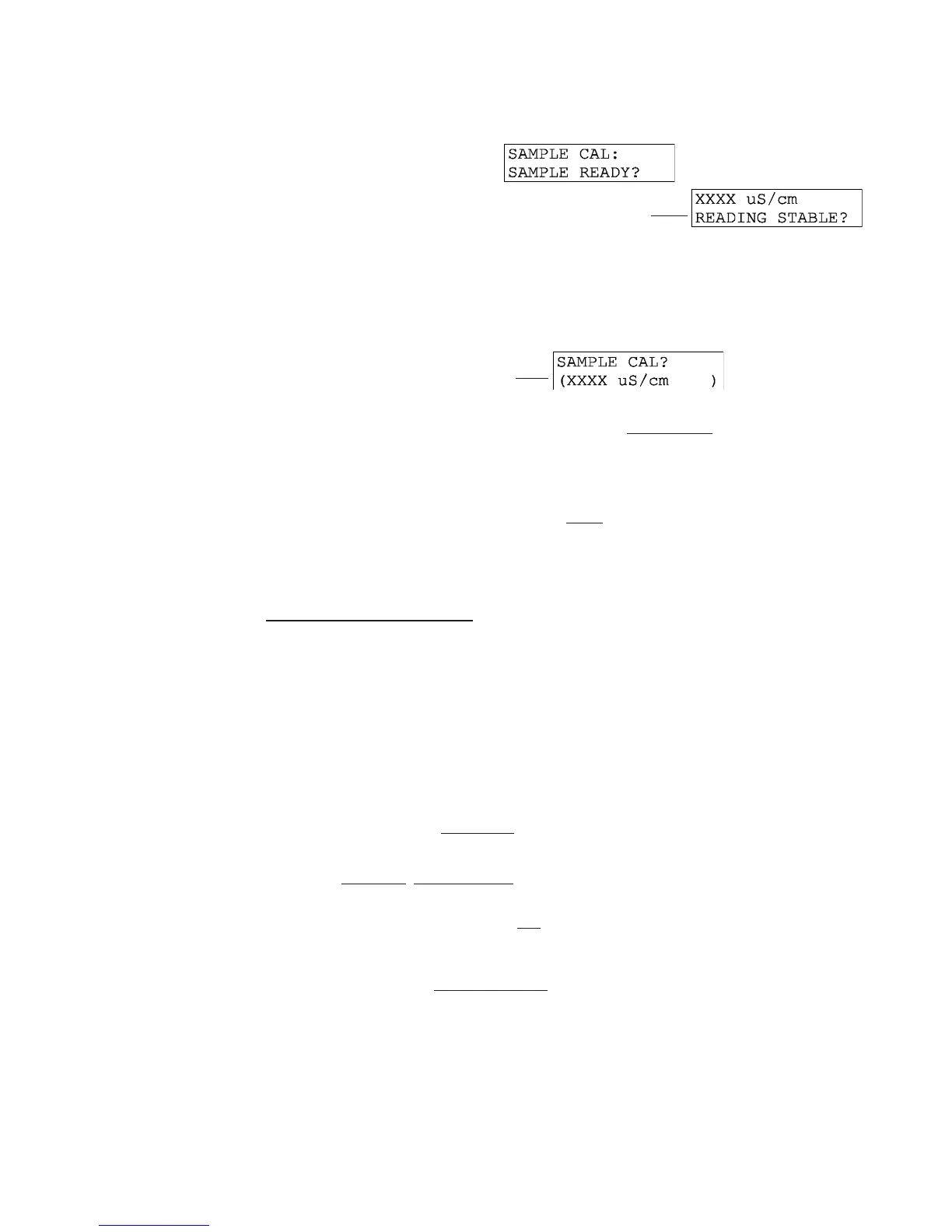

9. Press ENTER key to display . With the decade box

connected, press ENTER key again to confirm. This active

screen appears showing the measurement reading.

NOTE: During calibration, the analog output is automatically “held” at the last measured

value.

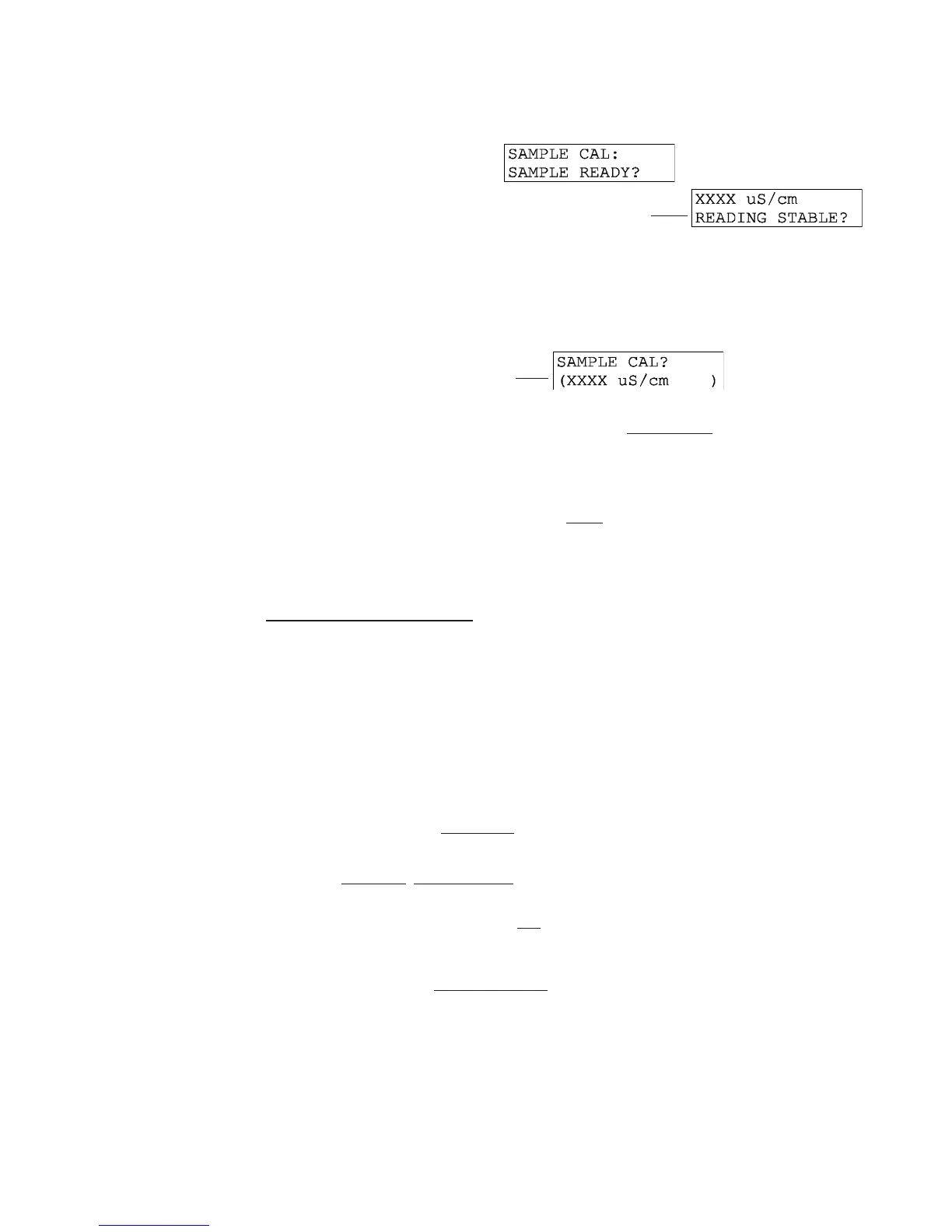

10. Wait for the reading to stabilize which may take up to 30 minutes. Then press ENTER

key. The “PLEASE WAIT” screen may appear if the reading is still too unstable. After

the reading has stabilized, this

static screen appears

showing the “last measured” value.

11. Use arrow keys to adjust the displayed value to exactly match the desired conductivity

value used in the calculation..

12. Press ENTER key to enter the value and complete calibration (“CONFIRM CAL OK?”

screen appears).

13. Press ENTER key again to display the active measurement reading on the “CONFIRM

ACTIVE?” output status screen. When the reading corresponds to the actual typical

process value, press ENTER key again to return the analog output to its active state

(MEASURE screen appears).

This completes ELECTRONIC CAL calibration.

8.4 % Concentration Calibration8.4 % Concentration Calibration

8.4 % Concentration Calibration8.4 % Concentration Calibration

8.4 % Concentration Calibration

After zeroing the sensor (first-time sensor calibration only), calibrate the sensor span using one

of these methods:

• CONC CAL Method: This method requires you to immerse the sensor into a prepared

% concentration reference solution of known value, or to keep the sensor installed in

the process while obtaining a process sample. When keeping the sensor installed,

determine the process value by laboratory analysis or comparison reading. In either

case, enter the known reference solution or sample % concentration value.

• COND CAL Method: This method requires removing the sensor from the process,

immersing it into a

conductivity reference solution, entering a reference for temperature

compensation temperature, and entering the known linear % per °C slope and conduc-

tivity value of the reference solution. The conductivity reference solution should have

an equivalent, uncompensated value that corresponds with the normal % concentration

value of the process.

1. Depending on the situation, do one of the following:

• When Keeping Sensor Installed:

Obtain a sample of the process solution and determine its value using laboratory

analysis or a recently calibrated portable meter.

• When Immersing Sensor in Reference Solution:

A. Prepare a % concentration reference solution using your normal method. To

achieve accurate calibration, the reference solution must have the same

chemical composition as the process. Also, its value should be near the typical

measured process value.

Loading...

Loading...