FlexiROC T35 R/T40 R 6 Operating

86 No: 3171473547.1 en

!

NOTE: Low tramming speed gives the highest traction and vice

versa.

6.

Operate the levers to move the drill rig in the desired direction. Levers S174 and

S175.

!

NOTE: If one crawler track is operated while the other is stationary

the tracks are subjected to unnecessary stresses. This should

therefore be avoided.

!

NOTE: A horn and a beacon indicate that the drill rig is reversing.

7.

Use the switches for track oscillation to keep the drill rig as level as possible.

Switches S176 and S177.

8.

Use the boom system to optimise the stability of the rig (See chapter: General prin-

ciples of tramming).

6.7 Checking after tramming

All emergency stop wires and all emergency stops must be checked after tramming.

6.8 Tramming - General principles

6.8.1 Tramming, general

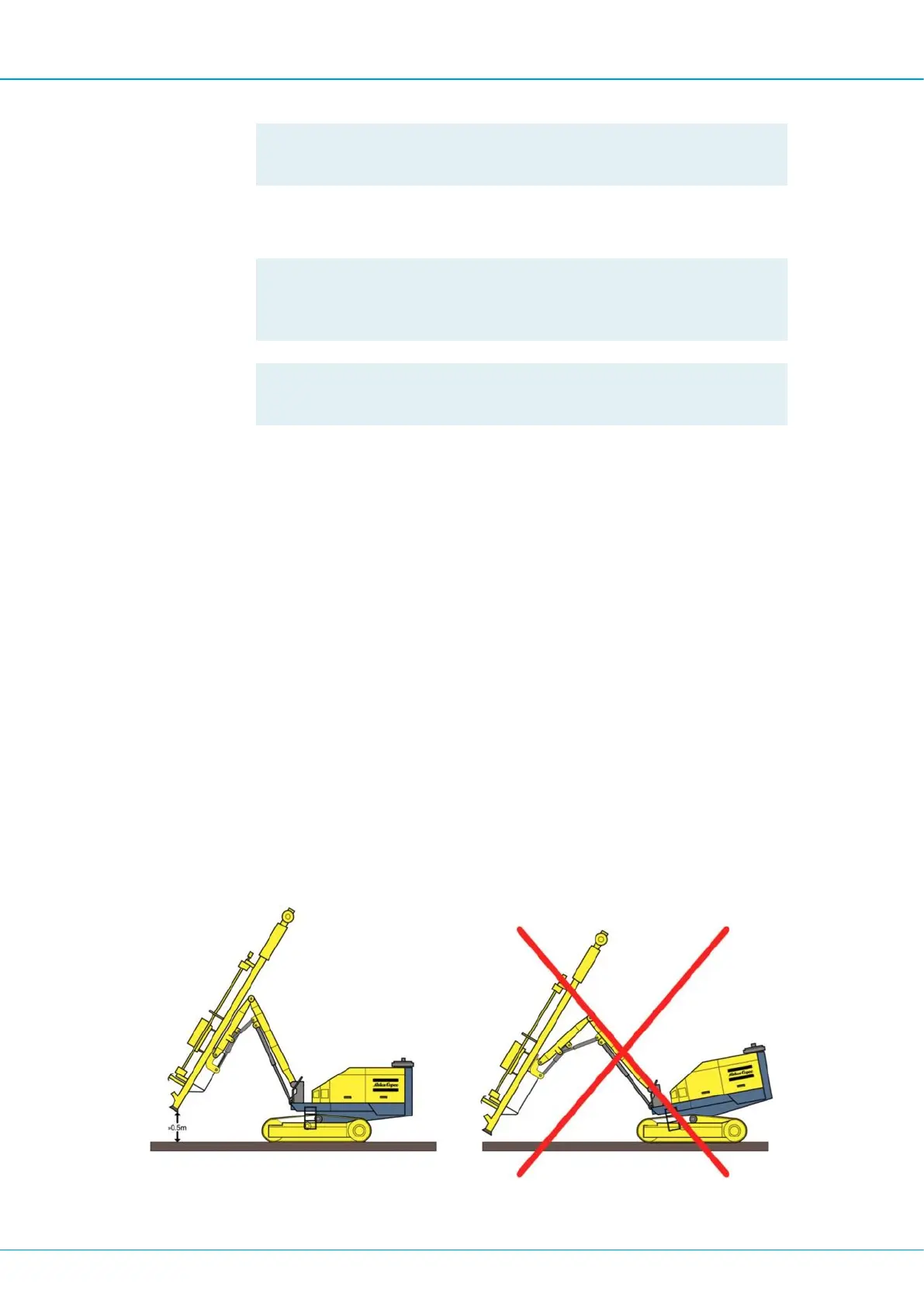

Direct the boom system straight ahead, contract the boom and position the feeder against

the outer boom before opening the track oscillation lock.

While tramming, the track oscillation lock must be open so that the caterpillar tracks can

move freely whenever there is a change in terrain. Use track oscillation to keep the chassis

frame as horizontal as possible.

Adapt the speed to the terrain. Always check the terrain where the drill rig will be man-

oeuvred.

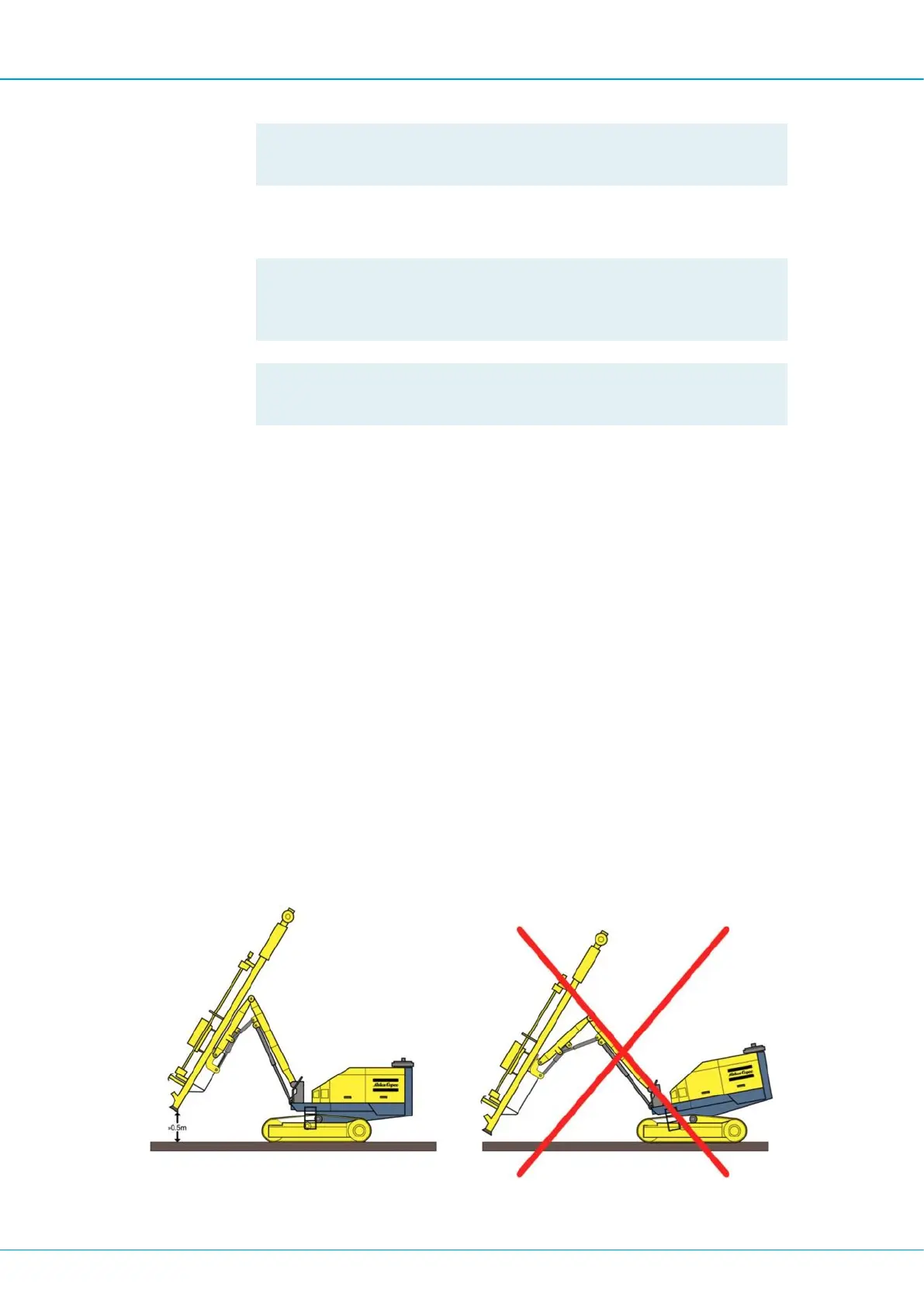

Left: Correct position for general tramming. Right: Wrong position.

Loading...

Loading...