- 6P10 PILOT MANUAL

-

14

4.3 - Electrical connections

4.3.1 - Power electrical connections

• During the transport, an accidental

loosening of the electrical connections can

occur.

• In order to eliminate any risk of anomalous

overheating, a control of the tightening of the

connections is strongly recommanded.

See § «Spare parts list - electrical boxes»

The rules and regulations in the country of

installation MUST be respected (standard

C15-100).

• The electrical lines for general power supply to

the circuits must be made in compliance with your

country’s current rules and regulations (standard

C15-100).

• Standard C15-100 determines the cable section to

be used based on acceptable currents.

• Standard C15-100 determines the cable section to

be used based on the following elements:

- Nature of the conductor :

. type of insulation, number of strands, etc...

- Installation mode :

. in uence of conductor and cable groups

. ambient temperature

. tightly or non-tightly installed

. length of cables, etc...

4.3.3 - Power electrical connection of the pilot

Electrical supply must be protected by an omni-polar power cut-

o device having a 3mm minimum spacing (EN 60335.1) : fuses or

circuit breakers must be calibrated according to the power of the

pilot.

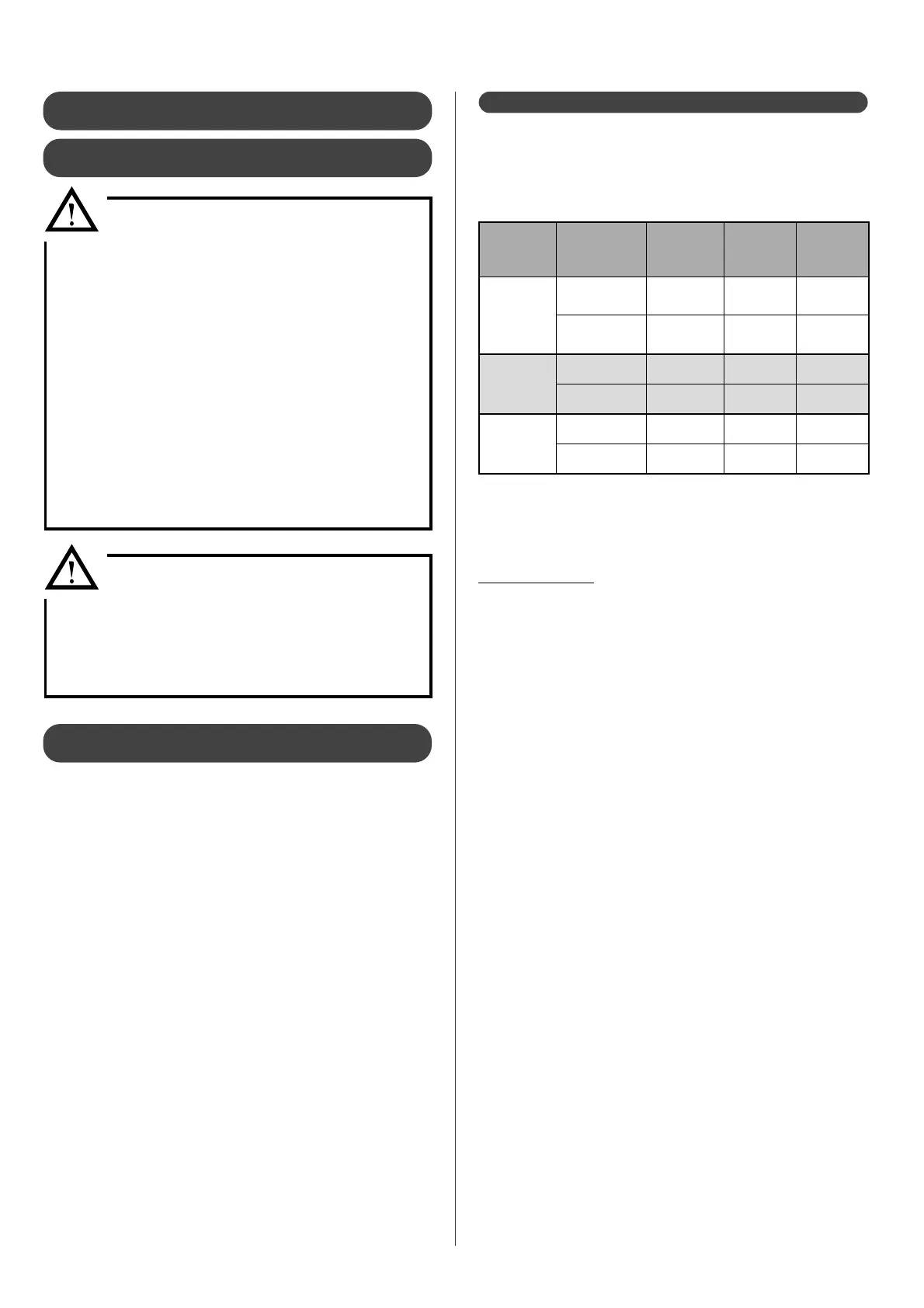

Electrical protection - 6P10 (with electrical back-up)

Number of

circulator

pumps

Supply

voltage

Cable cross-

section

Maximum

intensity

called

Circuit

braker

2

230V mono

3 G 6 mm² to

3 G 10 mm²

27,9 A 32 A

400V tri

5 G 2.5 mm²

to 5 G 4 mm²

9,3 A 16 A

3

230V mono 6 to 10 mm² 28,7 A 32 A

400V tri 2,5 to 4 mm² 9,5 A 16 A

4

230V mono 6 to 10 mm² 29,4 A 32 A

400V tri 2,5 to 4 mm² 9,8 A 16 A

Plan for a circuit breaker dedicated to the power supply of the Pilot

on the electrical panel. It must be able to completely cut-o the

electrical supply from the network (all-pole) to eliminate any danger

when carrying out maintenance on the appliance.

How to proceed:

• Check that the «ground» cable is connected properly to the

grounding peg or grounding network of the building.

• Connect the Pilot’s electrical cable to the dedicated plug,

equipped with a circuit breaker.

• Leave the pilot switched o until set-up.

• If a back-up boiler has to be connected ensure it is powered

o before any action.

The proper voltage is: 230 V (+10% / -15%).

Each appliance is delivered from the factory completely pre-wired.

However, it is necessary to connect the following elements to the

relevant terminals:

• The general electricity supply.

• The di erent sensors or thermostats on the Pilot.

• The 2-core shielded cable connecting the Pilot and the Heat

pump (10m length supplied).

• The back-up boiler (optional)

For three phase 400V electrical connection, refer to § «Electrical

Power Connection»

Under no circumstances will the manufacturer be held liable for

any problems which may arise due to improper installation and/or

choice of power supply cable.

4.3.2 - Prior recommandations before power

electrical connections

Check:

• The power consumption

• Number and thickness of the power supply

cables

• Fuse or circuit breaker ratings

The power supply must come from an electrical protection and

sectioning device which complies with all current rules and

regulation in e ect in the country of use.

This CE-approved unit complies with all the essential requirements

of the following directives:

- Low voltage n°2006/95/CE

- Electromagnetic compatibility n° 2004/108/CE

Ensure that the installation is equipped with a properly sized and

connected grounding cable.

Ensure that the voltage and frequency of the general power supply

ts requirements.

The acceptable variation in voltage is:

230 V -10% to +6% 50Hz for single-phase + Ground models.

400 V -10% to +6% 50Hz for three-phase + Neutral + Ground models

Under no circumstances will the manufacturer be held liable for

any problems which may arise due to improper installation and/or

choice of power supply cable.

Electrical supply of each device must be done power off by a

quali ed professional.

Loading...

Loading...