- 6P10 PILOT MANUAL

-

9

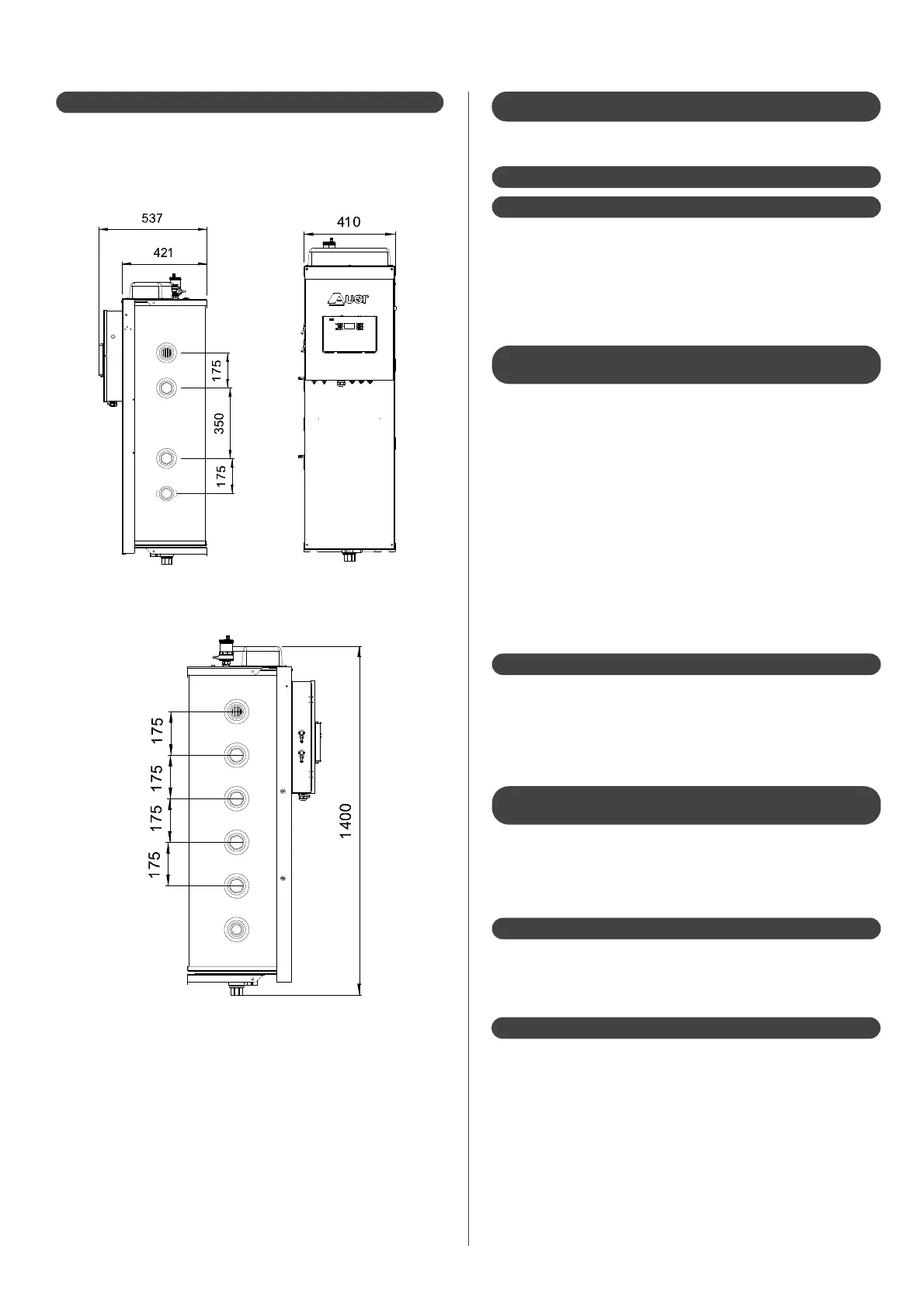

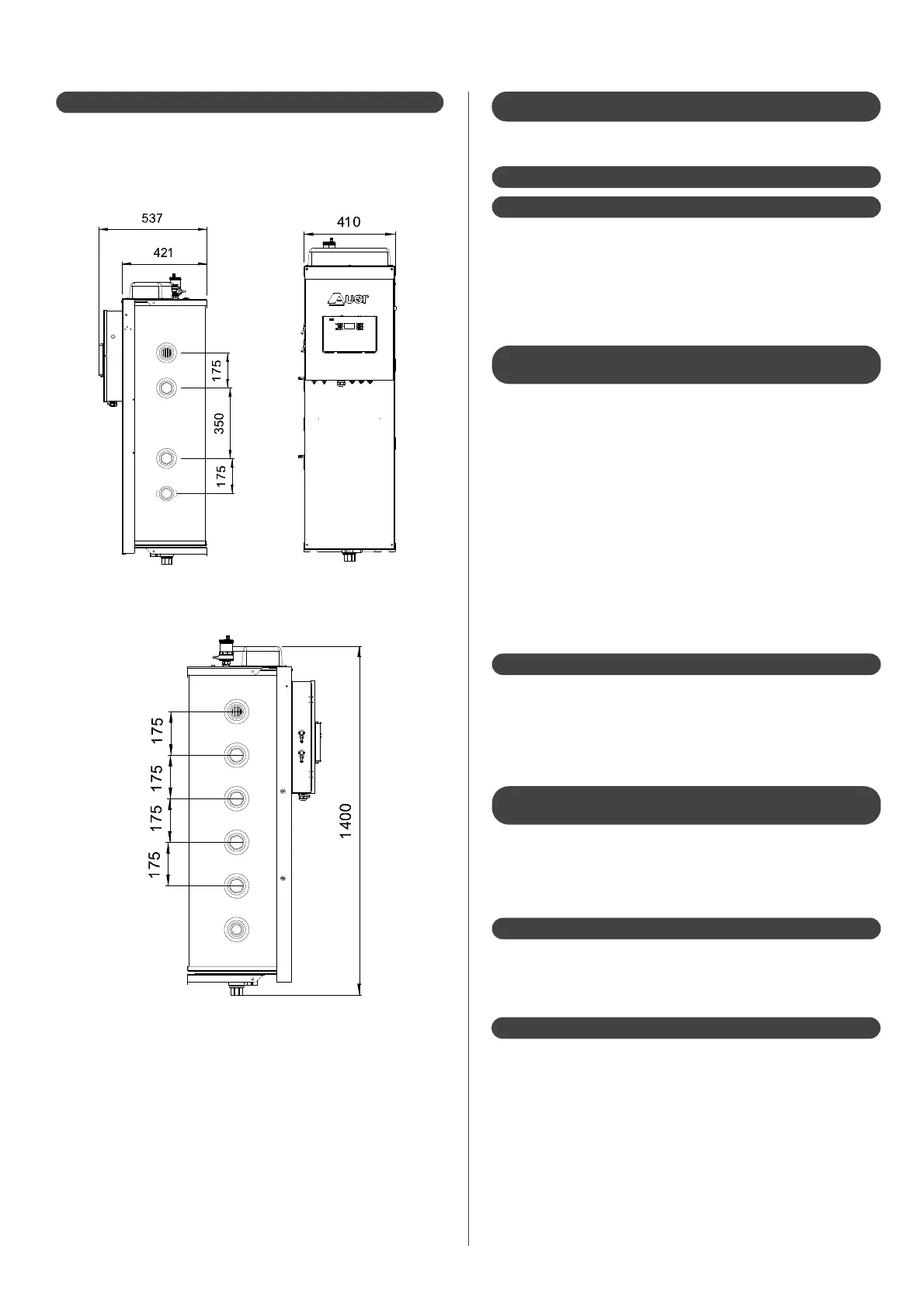

4.1.3 - Dimensions

The pilot must be placed at least 200mm above the oor or any

obstacle the enable it to be drained.

It must be placed at least 400mm under the ceiling to facilitate

the access to the air bleed and to the electrical back-up.

4.2.1 - Recommendations

A type CB backflow prevention device may be installed. This

device must be at di erent, non-regulated pressure zones. Check

your national laws and regulations to know if this is an obligatory

requirement. The backflow prevention device is designed to

prevent incoming heating water from entering the drinking water

circuit. It must be connected to the mains drainage system.

4.2.1.1 - Back ow prevention device

A su cient ow rate should be ensured so that the di erence in

temperature between the outlet and inlet points does not exceed

6°C. In an installation equipped with thermostatic mixing valves, this

inspection must be done with all taps/valves open.

The output actually needed determines the water ow rate of

the heating circuit and allows to calculate the dimensions of the

distribution network.

Adapt the speed of the circulator pump to the hydraulic

characteristics using the ow rate/pressure curve provided.

All necessary measures must be taken to ensure that the installation

can be continuously purged. Automatic air purging valves should be

placed at each high point of the installation, and manual air purging

valves should be installed on each radiator.

4.2.1.2 - Cross sections, purging of the

heating circuits

4.2 - Hydraulic installation

Consult the hydraulic schematic diagrams in the appendix.

Plan for a desludging tank with a su icient volume at a low point

on the inlet of the heating circuit. This tank must be equipped

with a drain so it can collect the oxides, particles, and calamines

which detach from the inner walls of the heating circuit while it is

in operation.

4.2.1.3 - Desludging tank

Before placing the pilot and heat pump, it is necessary to rinse the

installation with an appropriate product. This allows to eliminate all

traces of soldering waste, joint ller, grease, sludge, metallic particles,

etc... in the radiators, under oor heating, etc...

4.2.1.4 - Preparing the hydraulic circuit

(rinsing)

4.2.1.5 - Insulation of the pipes

Insulators must be in accordance with DTU 67.1.

All the apparent pipes and accessories (circulator, expansion vessel,

valve, ...) must be insulated or placed in insulated box.

4.2.1.6 - Expansion vessel

The installation must be equipped with an expansion vessel with

a su cient capacity (which depends on the static height of the

installation, the blowing-up pressure of the expansion vessel and

the volume of the installation)

Loading...

Loading...