A-9

Appendix A Maintenance and Troubleshooting of this Device

A2-4-6 Parameter adjustment

If diagnosis is judged to be not possible, the data collected under normal operating conditions

(section A2-4-2) and when there is simulated clogging (section A2-4-3) can be analyzed and the

parameters adjusted.

The reason why diagnosis cannot be performed is that the index value—even under normal

operating conditions—is similar to or smaller than that when there is clogging, so the normal and

clogged states cannot be distinguished. There are two primary causes leading for this situation.

• A large amount of variation of the index under normal conditions

• A small variation of the index when there is clogging

This situation may be improved by adjusting the parameters of the pressure frequency index

diagnosis. The following describes the two cases.

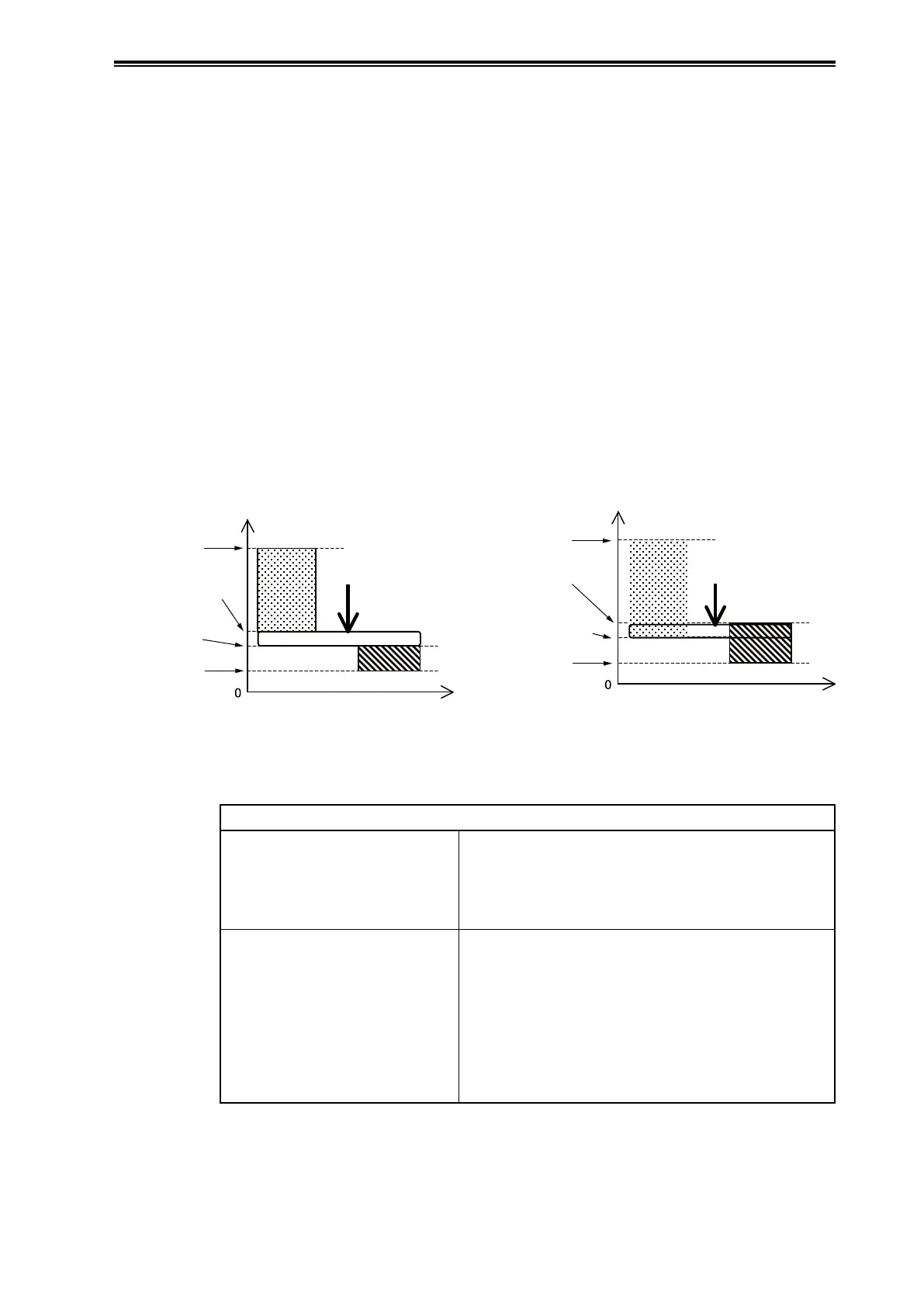

(A) Variation of the index under normal operating conditions is large.

In this case, although the value of the index is small with simulated clogging, variation in the index

is large under normal conditions, so the index value can be close to or equivalent to its value with

clogging even when there is no clogging, as shown in the figure below.

Index value Index value

Maximum value

under normal

operating conditions

Minimum value

under normal

operating conditions

Maximum value

under simulated

clogging

Minimum value

under simulated

clogging

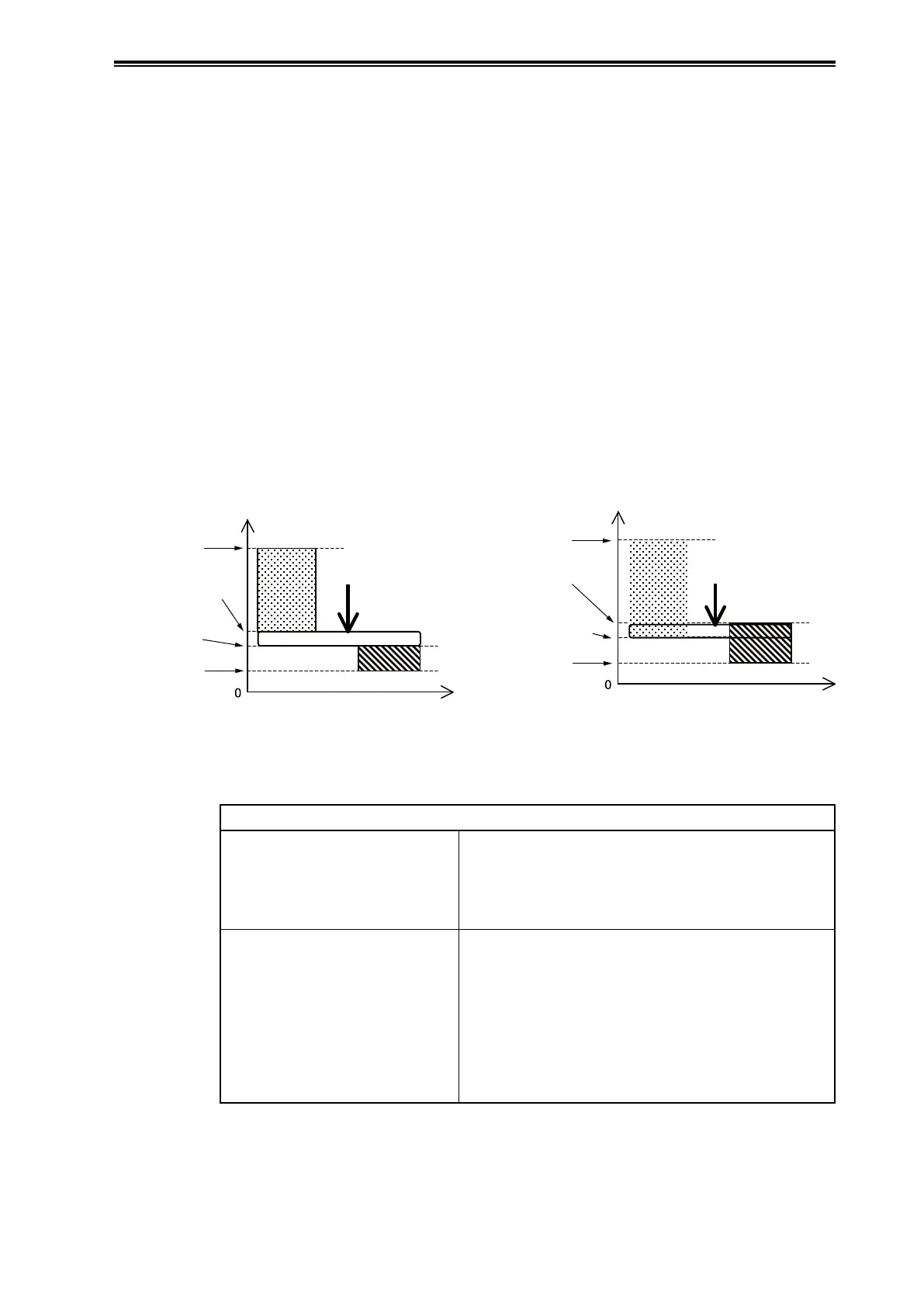

Maximum value

under normal

operating conditions

Minimum value

under normal

operating conditions

Maximum value

under simulated

clogging

Minimum value

under simulated

clogging

Normal condition Simulated clogging

Normal condition Simulated clogging

condition

Slight dierence Value being overlapping

In this case, it is necessary to examine the cause of the large variation that occurs under normal

conditions, and to reduce this effect. Use the following the guidelines for adjustment.

Guidelines for parameter adjustment

The index value sometimes

decreases significantly under normal

operating conditions. At this time,

the process variable changes or the

standard deviation becomes large.

Increase the Press Freq Filter Constant in steps of 0.02–

0.05.

The index value under normal

operating conditions changes

significantly depending on the

operating conditions.

Check whether the operating conditions are related to the

process variable. If there is a PV range where the difference

between the maximum index value and the minimum is

relatively small, or a PV range where the minimum under

normal conditions is not small, set Press Freq Calc PV

High Limit and Press Freq Calc PV Low Limit to the values

of this range. When these parameters are used, diagnosis

should be carried out only when pressure is applied, and

should be stopped when no pressure is applied.

Loading...

Loading...